Challenges And Solutions Of Tajima Embroidery Machine

In this article, we will explain the top five most common Tajima embroidery machine problems. So, easily solve any challenges with our efficient solutions and complete your embroidery projects with more proficiency and exactness.

Tajima is an embroidery machine that is marketed and created by Hirsch. Unlike most other embroidery machines, Tajima offers you advanced networking technology that allows you to connect as many embroidery machines as you want, hence making it perfect for bulk production. But sometimes you might face some challenges with the Tajima embroidery machine.

So, have you ever faced problems with Tajima Embroidery Machines?

If yes, this article is for you!

Tajima Embroidery Machine:

Tajima embroidery machine is the best commercial embroidery machine that is established in China with the vision to cope with increasing worldwide marketing demands so that everyone can run off their own embroidery business. Tajima is known as a brand that introduced a lot of creativity in the textile business and it has been playing an important role in worldwide growth and development.

On the contrary, you get stuck because of bobbin thread issues, thread Breaks, sewing, tension, or code errors in the Tajima embroidery machine. These issues waste your time and lose focus on the quality of your embroidery projects.

Challenges & Solutions Of Tajima Embroidery Machine:

1. Error Codes Of Tajima Embroidery Machines:

There are a few codes that are used in defining the errors in your Tajima embroidery machine in the form of letters or numbers. Every code is specific for the malfunction of each part of the machine.

So, the question that might hit your mind is how you would know that your machine has this error. Well, your Tajima embroidery machine will automatically give you a code that will be shown on the display.

Solution:

– The error codes list is given in the manual guide given to the consumers that help you in resolving Tajima embroidery machine problems.

– You are recommended to read this manual carefully.

– If you have sufficient know-how of these error codes, you would be able to solve the problems really quickly.

2. Improper Machine Functioning:

Your machine might not work properly sometimes, which can be irritating and eventually a waste of your time. This might happen because of various reasons that include:

– Improper threading

– Presser’s foot isn’t placed properly

– Unwounded bobbin

Solution:

– You can refurbish the functioning of the Tajima embroidery machine just by threading it correctly. And it can be simply done by the proper insertion of the needle in the position by taking the hand wheel to its peak point.

-Uplift the presser foot of the machine while loading. The machine’s foot must be down before you start any embroidery work.

– The use of a pre-wound bobbin is suggested which results in fine stitches and helps to prevent any hassle during embroidery. Make a routine to check your bobbin on a daily basis.

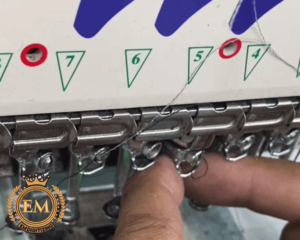

3. Problems With Bobbin Adjustments:

It is a very important step to adjust the bobbin rightly before embroidering any projects. A lot of us get annoyed when the top thread color doesn’t match the bobbin thread. At this point, an error code of 291 is going to be shown on the screen which means there is an issue with the bobbin thread. This problem occurs when you don’t trim the former color. In addition to that, these issues might be connected to your electronic machine. Possibly your machine displayed this error because you did not clean your needle plate and your thread began hooping.

Solution:

– First and foremost, it is important to use the highest quality bobbin thread in order to avoid damage to your machine and embroidery. So the use of Tajima’s branded bobbin is extremely recommended.

– Along with this, never leave your needle plate unclean and your gadget without greasing it for smooth and efficient working.

– To avoid thread looping, you have to check and properly replace your needle.

4. Wrong Placement Of Needle:

If you ever faced that your machine is not stable to hold the thread, this is because of a firm grip on your needle thread. At some point, you get tangled on the top thread and the machine will stop automatically. It means you are using an old and damaged needle.

Solution:

– Ensure to check the appropriate needle for your embroidery projects and properly replace it if you are using an old or damaged needle.

– Right insertion of needle and thread is important to perform stitching smoothly and efficiently.

5. Thread Tension:

You are suggested to adjust the top tension rightly as this is a matter of energy and time you are investing to embroider a project. It is ideal to test the tension on a scrap piece of material by changing the color of the thread. Loose or tighten the top and bobbin thread tension is controlled by adjusting tension in order to prevent your thread from seeing on the top and for even stitching.

Winding Up:

Tajima embroidery machines are considered to be the best commercial embroidery machines and have been offering services for a lot of years now. It is very common to face issues while dealing with electric devices. One of the best features that are offered by the Tajima embroidery machine is its manual guide for users where all the details are mentioned from its features to the working mode.

We hope you enjoyed reading this article as we did in writing.

If you want to customize embroidery logo digitizing, EM DIGITIZING will be your best choice. At EM DIGITIZING, we deliver the best embroidery logo digitizing services with the best quality. We offer 50% off on all our services to our potential customers on their first order. So, get a free quote now and we will get in touch with you.

Hope this article will be helpful for you guys!

If there’s any question related to this article feel free to comment to us. And, thanks for reading!

No doubt the Tajima embroidery machine is considered one of the best embroidery machines, and especially if you are considering a commercial multi-needle embroidery machine then you would appraise the quality of the Tajima embroidery machine positively. Tajima is an advanced embroidery machine made by Hirsch in China in 2001. It is not like an ordinary machine; Tajima provides you with modern networking equipment that enables you to connect a lot of embroidery machines, hence making it perfect for bulk production.

Tajima embroidery machine is the best commercial embroidery machine that is established in China with the vision to cope with increasing worldwide marketing demands so that everyone can run off their own embroidery business. Tajima is known as a brand that introduced a lot of creativity in the textile business and it has been playing an important role in worldwide growth and development. On the contrary, you get stuck because of bobbin thread issues, thread Breaks, sewing, tension, or code errors in the Tajima embroidery machine. These issues waste your time and lose focus on the quality of your embroidery projects.

Error codes of Tajima embroidery machines:

There are a few codes that are used in defining the errors in your Tajima embroidery machine in the form of letters or numbers. Every code is specific for the malfunction of each part of the machine.

So, the question that might hit your mind is how you would know that your machine has this error. Well, your Tajima embroidery machine will automatically give you a code that would be shown on the display.

Solution:

– The error codes list is given in the manual guide given to the consumers that help you in resolving Tajima embroidery machine problems.

– You are recommended to read this manual carefully.

– If you have sufficient know-how of these error codes, you would be able to solve the problems really quickly.

Improper machine functioning:

Your machine might not work properly sometimes, which can be irritating and eventually a waste of your time. This might happen because of various reasons that include:

– Improper threading

– Presser’s foot isn’t placed properly

– Unwounded bobbin

Solution:

– You can refurbish the functioning of the Tajima embroidery machine just by threading it correctly. And it can be simply done by the proper insertion of the needle in the position by taking the hand wheel to its peak point.

-Uplift the presser foot of the machine while loading. The machine’s foot must be down before you start any embroidery work.

– The use of a pre-wound bobbin is suggested which results in fine stitches and helps to prevent any hassle during embroidery. Make a routine to check your bobbin on a daily basis.

Problems with bobbin adjustments:

It is a very important step to adjust the bobbin rightly before embroidering any projects. A lot of us get annoyed when the top thread color doesn’t match the bobbin thread. At this point, an error code of 291 is going to be shown on the screen which means there is an issue with the bobbin thread. This problem occurs when you don’t trim the former color. In addition to that, these issues might be connected to your electronic machine. Possibly your machine displayed this error because you did not clean your needle plate and your thread began hooping.

Solution:

– First and foremost, it is important to use the highest quality bobbin thread in order to avoid damage to your machine and embroidery. So the use of Tajima’s branded bobbin is extremely recommended.

– Along with this, never leave your needle plate unclean and your gadget without greasing it for smooth and efficient working.

– To avoid thread looping, you have to check and properly replace your needle.

Wrong placement of needle:

If you ever face that your machine is not stable to hold the thread, this is because of a firm grip on your needle thread. At some point, you get tangled on the top thread and the machine will stop automatically. It means you are using an old and damaged needle.

Solution:

– Ensure to check the appropriate needle for your embroidery projects and properly replace it if you are using an old or damaged needle.

– Right insertion of needle and thread is important to perform stitching smoothly and efficiently.

Thread tension:

You are suggested to adjust the top tension rightly as this is a matter of energy and time you are investing to embroider a project. It is ideal to test the tension on a scrap piece of material by changing the color of the thread. Loose or tighten the top and bobbin thread tension is controlled by adjusting tension in order to prevent your thread from seeing on the top and for even stitching.