As any experienced embroiderer knows, if you’re looking for beautiful results, stabilizer is important component when creating almost any embroidery project. In this article, I will explain all about embroidery machine stabilizers: What are the main types of stabilizers and when should I use them? What brand of stabilizer should I use?

A stabilizer (referred to in industrial circles as backing) is essential for machine embroidery. It is used to support the fabric during the stitching process to keep puckering or stretching from occurring. We will help you get more professional results and become a better embroiderer.

The choice of stabilizer can make or break an embroidery project. Using a stabilizer that is insufficient for the fabric or the stitch count of the design can make even the best-digitized design look bad.

Stabilizers are classified by the method used to remove the excess from the back of the project after the design has been stitched. The three most common types are:

- Cut-Away

- Tear-Away

- Wash-Away

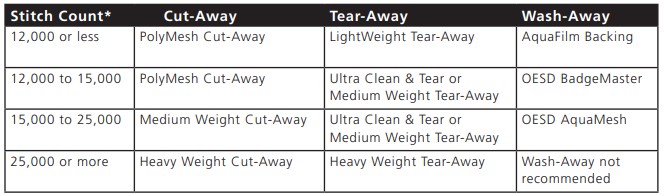

Within each group are several weights of stabilizers.

- Select the weight that most closely corresponds to the importance of the fabric to be embroidered.

- Selecting the weight according to the design’s stitch count – the greater the stitch count, the heavier the stabilizer should be.

We are adhering any one of these stabilizers to the fabric with a temporary adhesive spray before hooping is recommended to keep the layers from shifting during the embroidery process and to make the item easier to hoop.

Why Is Stabilizer So Important? Stabilizers are the foundation of your embroidery and is a necessity to support your fabric and threads. Without the use of stabilizer the registration of the design may be off, you might have puckering, and your fabric may distort. Your choice of stabilizer can “make or break” your embroidery project.

Embroidery Digitizing Services

Choosing Stabilizer for embroidery machine

The most important factors to consider when choosing a suitable stabilizer are: fabric, embroidery design, back appearance, and “Hand” or Feel

Fabric

- The most important rule is — Use a cutaway stabilizer when embroidering on knits or stretchy fabrics.

The cutaway will support the stitches not only during the embroidery process itself but also during the lifetime of the garment.

- Fabric weight and stabilizer weight should be compatible. In general, the heavier the fabric, the heavier the stabilizer should be. Conversely, the lighter, softer, or more drapey the material, the lighter the weight of the stabilizer should be.

- A piece of sheer fabric will require a water-soluble stabilizer so that no remaining bits of stabilizer will be seen from the right side.

- The fabric and chosen design should be compatible.

A lightweight fabric can become overwhelmed by a stitch-intensive design. Conversely, an open, airy design can become visually lost in a napped or heavy fabric.

Embroidery Design

- The more stitches in a design, the heavier the stabilizer should be.

- Use a best digitized design with sufficient underlay to provide base support for the stitches.

- If you must use a particular type of stabilizer, choose the design accordingly.

Back Appearance

- If you want absolutely no stabilizer to show from the wrong side, you must use a water-soluble stabilizer.

- If you are OK with most of the stabilizer being removed, you can use a tear-away.

- When using a cutaway stabilizer, the excess must be cut away, leaving a circle of stabilizers on the backside of the project.

The “Hand” or Feel

- The weight and type of the stabilizer will influence the drape of the fabric.

– A heavyweight stabilizer will add weight to the garment, and a heavy tear-away stabilizer will add weight since some stabilizers will remain behind the stitches.

– The lighter the weight of the stabilizer, the greater the drape of the fabric will be.

– Awash away stabilizer will add no weight to the fabric after it is washed.

- The cut edges of a cutaway stabilizer remain on the backside of the project. The heavier the cutaway, the more irritating this edge could be on a garment that will be worn directly against the skin.

Testing Results

Testing is always highly recommended. Even though you follow all the stabilizer guidelines, they are

just that – guidelines. There are many variables in fabric quality within each fabric grouping and differences in the quality of the design. The best way to determine the proper stabilizer is to test.

*this test performed by Bernina Stitch counts are provided as a guideline only. There are many additional factors to consider, including design density. Design density is the relationship between the stitch count and design size. For example, a 4” design with 15,000 stitches will need a heavier stabilizer than an 8” design with the same number of stitches. For best results, do a test sew of your design.

Types of Embroidery Stabilizers

Technically, there are three types of embroidery stabilizers that’s tear-away, wash-away and cut-away , we will also discuss some specialty stabilizers. Each of these three types of stabilizers may also be available as a fusible and or tacky.

What types of stabilizers should I use them? When making your decision on which type of stabilizer to use a good rule of thumb is to:

- Use a Tear Away Stabilizer if the fabric is stable and woven.

- If you can make sure to fuse your stabilizer with your fabric.

- Utilize the Cut Away stabilizer in the event that the fabric has stretch like sweatshirts, t-shirts or knits.

- Utilize a Wash Away when you are using sheer fabric or freestanding lace designs such as the Vintage Lace, 3D Flowers, 3D Butterflies, or 3D Leaves, etc.

Apart from the three kinds of stabilizers available, the majority of brands also offer special products that you can use for your embroidery. These include fabric preparations to stabilize fabrics that break, stretch or pucker. It also will increase the stitch count of your fabric, making it perfect for the design of a high stitch count.

There are products that offer different textures. They give a firm or a soft foam form that aids in the applique process without adding weight, and also make sure that the stitches are covered so they do not irritate the skin. They do not substitute for stabilizers by any means but they can all be used in conjunction with tear away or removed stabilizers.

Cut-Away Stabilizers

Cutaway stabilizers are regarded as to be the most stable of the three types of stabilizers.

They can be applied to any kind of fabric but should be used for stitching on stretchy or knit fabrics. The stabilizer that is not used is removed but the stabilizer in front of the stitches will remain throughout the life of the fabric and will stop the design’s stitches from popping out when the garment is stretched or altered.

They can be applied to any kind of fabric but should be used for stitching on stretchy or knit fabrics. The stabilizer that is not used is removed but the stabilizer in front of the stitches will remain throughout the life of the fabric and will stop the design’s stitches from popping out when the garment is stretched or altered.

Removal:

- Don’t attempt to cut open spaces within the design.

- Trim the design with scissors, but not more to 1/8 ” to 1/2 ” away from the design’s edge and trim any edges.

- Lay the project on the stabilizer side facing up. Place the fabric between your fingers then cut it with the stabilizer. This will stop you from cutting the fabric!

Heavy Weight Cut-Away

- Available in black or white

- Ideal for sweatshirts and luxurious fabrics.

- The strongest stabilizer can support the greatest amount of stitches

Medium Weight Cut-Away

- Ideal for medium-weight T-shirts and fabrics

- It will offer better support than smaller cut, but it will be less rigid than a more heavyweight

PolyMesh Cut-Away

- Available in beige, white and black

- Very little shadow that reaches one side

- Soft and soft on the skin

- Tiny shadows when used on a weave fabric like batiste

- Ideal for baby or children’s clothes and stretchy, lightweight fabrics

- White PolyMesh is also available in a fusible version (see specialties Stabilizers)

Tear-Away Stabilizers

Tear-away stabilizers are used when you wish to remove most of the excess stabilizers from the back of the project after embroidery. They can be used on all fabrics, with the exception of stretchy fabric or knits or very sheer fabrics.

Tear-away stabilizers are used when you wish to remove most of the excess stabilizers from the back of the project after embroidery. They can be used on all fabrics, with the exception of stretchy fabric or knits or very sheer fabrics.

Removal:

- Place the embroidery with the stabilizer side up on a flat surface.

- Support the stitches with your fingers as carefully tear the excess stabilizer away.

- Some tight open areas within the design may be tough to remove and can be left on the back of the project. For most tear-away stabilizers, these areas will eventually begin to disintegrate with repeated washings.

Heavy Weight Tear-Away

- It supports a large number of stitches

- Tears away very cleanly and easily – stiff edges are easy to grasp

- Great for items that need more support for heavier stitch count designs

Medium Weight Tear-Away

- Available only in black

- Firm tear away, but very easy to remove

Ultra Clean and Tear

- A soft, medium weight tear-away stabilizer

- Removes very easily – does not stress the stitches as it is removed

- The remaining fibers will easily wash away as the project is laundered

Light Weight Tear-Away

- Easy to tear away, leaving a very clean edge

- It can be printed on and used for paper piecing

- Available in a fusible version (See Specialty Stabilizer section)

- Great for use when stitching decorative stitches on the sewing side

- The lightest weight of the tear-away stabilizers – adds very little weight to the project

Wash-Away Stabilizers

Wash away stabilizers should be used when all traces of the stabilizer need to be removed from the back of the project, such as when using a sheer fabric or embroidering a project that will be seen from the backside as well front. Since this type of stabilizer does not support as many stitches as tear-away or cutaway stabilizers, careful consideration should be given to the design choice. Do not use this stabilizer if your fabric cannot be washed. click here to learn about embroidery threads.

Wash away stabilizers should be used when all traces of the stabilizer need to be removed from the back of the project, such as when using a sheer fabric or embroidering a project that will be seen from the backside as well front. Since this type of stabilizer does not support as many stitches as tear-away or cutaway stabilizers, careful consideration should be given to the design choice. Do not use this stabilizer if your fabric cannot be washed. click here to learn about embroidery threads.

Removal:

- When creating lace, the more it is washed, the softer the lace will be.

- Remove as much stabilizer as possible by tearing or cutting away the excess.

- Rinse the project under warm running water until all traces of the stabilizer are removed.

AquaFilm Backing

- Too lightweight for stand-alone lace

- A clear, lightweight backing – quick to rinse away

- Use for quilting in the hoop if the quilt itself cannot be hooped

BadgeMaster

- A heavy clear backing

- It can be used for stand-alone lace

- The majority of stabilizers can be torn away before rinsing

AquaMesh

- It can be used in the creation of stand-alone lace

- An opaque backing that supports the most significant number of stitches

- Excess cannot be torn away – cut the lot away from the outer edges and then rinse

- A very stable water-soluble stabilizer that is not prone to premature perforation during stitching

Specialty Stabilizers

1: Fusible Stabilizers

Fusible stabilizers are used by cutting a hoop-sized piece of stabilizer and adhering it to the back of the fabric. This will prevent stretching of the fabric during the hooping process and will help to keep outlines correctly registered. The fabric/stabilizer is then hooped in the traditional manner.

Fusible Poly Mesh Cutaway Fusible Tear Away

To use:

- Remove the excess by either cutting away the Fusible PolyMesh or tearing away the Fusible Tear Away.

- Lightly adhere the adhesive side of the stabilizer to the back of the project in the area to be embroidered.

- After the embroidery has finished, carefully separate the stabilizer from the fabric (heating with iron very briefly may aid in this).

2: Paper-Backed Pressure Sensitive Adhesive Stabilizers

These stabilizers are used in the same manner. They are all coated with the same type of pressure-sensitive adhesive with a protective paper backing.

The difference will be in the number of stitches that the stabilizer will support as well as the manner in which the excess stabilizer is removed. Select the stabilizer type (cutaway, tear away, or water-soluble) by applying the same principles as if using a regular stabilizer. (Refer to the earlier page on stabilizers.)

Most generally, these stabilizers are used for “hoopless” embroidery.

Stabil-Stick Cutaway Stabil-Stick Tear Away

SQUAMISH PLUS (WATER-SOLUBLE)

To use:

- Hoop with the paper side up.

- Score and remove the paper to reveal the sticky surface.

- Position the fabric over the sticky surface and smooth it into place.

To remove:

- Separate the stabilizer from the fabric by gently pulling the layers apart.

- Remove the excess by either cutting, tearing, or washing it away, depending on the type of stabilizer used.

Check out 4 Best Embroidery Machines with detailed reviews pros and cons. Note we are not selling embroidery machines. Our comparison is 100% neutral.

3: Water Activated Stabilizer

Hydro-Stick Tear Away

Hydro-Stick is a heavyweight tear-away stabilizer with an adhesive coating that is activated by water. It is most often used for “hoopless” embroidery.

HydroStick holds the fabric VERY firmly. The project cannot be accidentally bumped or moved out of place during the embroidery process.

It will not gum the needles since it is not a sticky adhesive.

To use:

- Hoop the stabilizer with the coated side up.

- Allow the stabilizer to dry for a few minutes before embroidering.

- Moisten the top slightly with water and adhere the fabric to the top of the hooped stabilizer.

To remove:

- Continue to lift and moisten until the stabilizer has been separated. Then tear the excess away.

- Lift a loose corner of the stabilizer and apply moisture to the area between the stabilizer and the back of the fabric.

Toppings

As the name implies, toppings are used only on the top of the fabric to control the nap of the fabric. They are too lightweight to be used as the backing stabilizer.

AquaFilm Topping

- A clear water-soluble product – excess easily removed with water

- Improves the appearance of the embroidery design on any fabric with any kind of an irregular weave

- Must be used on napped fabrics such as towels, knits, velvets, or velveteens to prevent the nap of the fabric from poking through the stitches

To use:

- Place the AquaFilm over the top of the hooped fabric. Aquarium does not need to be hooped with the fabric, but it does need to be secured.

Moisten the corners and attach to the fabric; use Painter’s Tape or pins (carefully placed outside the stitching area) to hold the AquaFilm in place.

Use a design basting box or a hoop basting box to further secure the AquaFilm. Slow the machine down to its slowest speed as the basting box is stitched. Using the foot control on your machine will also give you greater control.

To remove:

- The remainder can be rinsed away with water.

- Carefully tear away as much of the aquarium as possible.

TopCover

TopCover is a vinyl-type product that prevents the color of the fabric from showing through the stitches as well as controlling the nap.

It is ideal for use when stitching light designs on dark fabric, or vice versa. The top cover behind the stitches will remain there throughout the lifetime of the project.

To use:

- Place TopCover over the top of the hooped fabric. It does not need to be hooped with the fabric, but it does need to be secured.

Use Painter’s Tape or pins to hold it securely.

Use a design basting box or a hoop basting box to further secure the top cover. Slow the machine down to its slowest speed as the basting box is stitched. Using the foot control on your machine will also give you greater control.

To remove:

- The needle perforations will make it easy to remove the excess. Tear away as much as possible.

- Tiny bits that cannot be torn away can be liquefied away with the tip of the iron. Be SURE to clean the iron after this use.

Guide Conclusion: You Need All 3 Types of Embroidery Stabilizer

Stabilizers come in different sizes and colours and are used for other fabrics and design types. Depending on what you embroider, you do need the three main types of stabilizers:

- Tear Away: used for any stable woven fabric that doesn’t stretch, such as leather, towels, vinyl.

- Wash Away: used for any sheer fabrics, such as organza, freestanding lace, 3D and cutwork designs.

- Cut Away: used for worn and washed products regularly—the most stable and good to use for heavy designs with large stitch counts.

FAQs

Cut Away Stabilizers are the most stable of all stabilizers and are permanent, and they will continue to support your stitches for the life of the project. Cut Away is always a good choice for any project that will be worn and washed regularly. Most brands have different weights of Cut Away – Heavy, Medium, or Mesh.

Stabilizers are pretty expensive, so you didn’t buy any. Instead, you can use dryer sheets, save them after drying my clothes, iron them, and reuse them. If you need a stiffer stabilizer, use it before it has been dried with your clothes, and it works great and makes your craft smell good!

Use a cutaway stabilizer, preferably a fusible no-show mesh. They keep knits from stretching out of shape and keeps embroidery where it belongs. Turn shirt inside and fuse a piece of no-show mesh significantly more important than the hoop size. Turn right side out, find your centre point and hoop the stabilized shirt.

One piece of medium-weight cutaway stabilizer is the best choice. The tear-away stabilizer may be used with the lightest designs, such as toile or vintage, and when topping is unnecessary.

Cutaway, you trim with scissors around the back of the design and tear away just tears away. Usually, with cutaway, you trim but leave some around the design (on the backside).

Always use a cutaway stabilizer for the best results because polyester fabrics are less stable than most fabrics.

Fundamental cutaway backing is the most commonly used. It’s a wet-laid nonwoven backing explicitly designed for machine embroidery.