If you’re looking to add extra flair and depth to your designs, 3D puff foam embroidery is the perfect technique to explore. This method allows you to create raised, eye-catching designs that make your embroidery stand out.

In this guide, we’ll cover everything you need to know, from choosing the right materials to mastering the stitching process.

Whether you’re new to the world of 3D embroidery or looking to improve your technique, you’ll find practical tips to create stunning, professional designs.

Let’s jump in!

Learn 3D Puffy Foam Embroidery: A Simple Guide for Beginners

Understanding 3D Puffy Foam Embroidery

It is a method where foam is placed beneath the embroidery stitches to create a raised, 3D effect. This technique gives your designs a bold, textured appearance, making them pop and adding an extra layer of visual interest.

Materials Needed for 3D Puffy Embroidery

To get started with 3D embroidery, you’ll need a few essential materials that ensure your design stands out with a bold, raised effect.

Here’s a list of the key supplies required to create professional-looking embroidery.

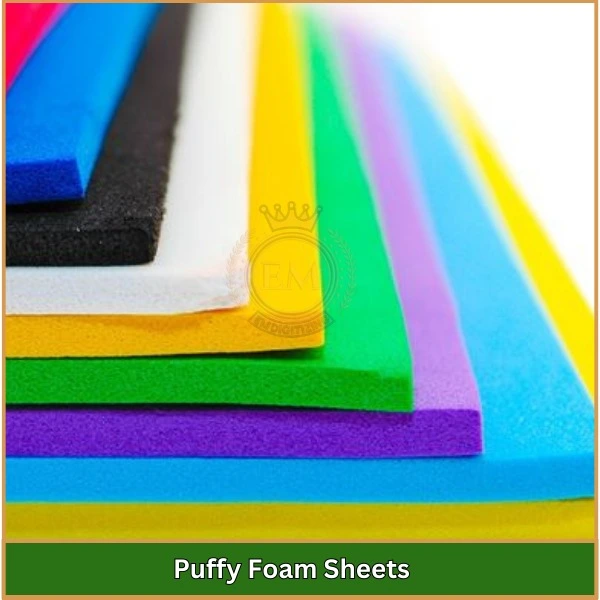

- Puffy Foam Sheets

- Embroidery Thread

- Fabric

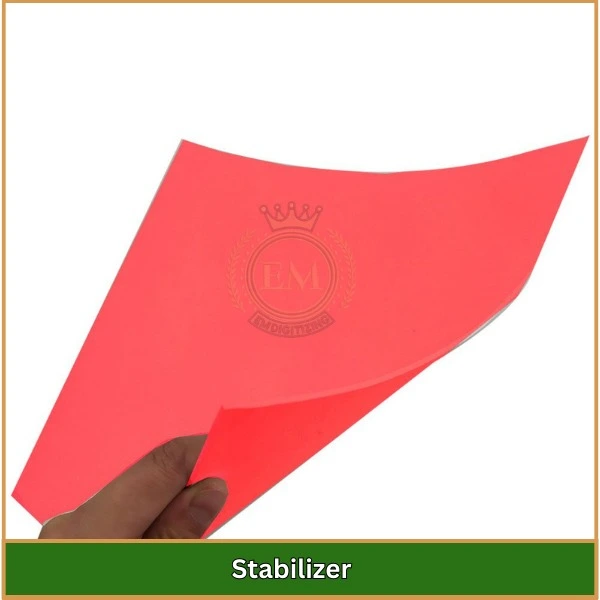

- Stabilizer

- Adhesive (Optional)

- Embroidery Machine

Puffy Foam Sheets

- Types: High-density polyethylene (HDPE) and polyurethane are the primary foams used, specifically tailored for embroidery purposes.

- Thickness: Available in 2mm, 3mm, and 6mm, with thicker foams creating a more pronounced 3D effect. Popular choices include E-Zee 3D Foam and Bodybuilder hard foam, both 3mm thick.

- Color: Typically found in white and black, select a foam color that contrasts with the thread to highlight the design effectively.

Which thickness of foam is recommended for 3d embroidery? For 3D puff embroidery, a foam thickness of 3mm is recommended as it provides the ideal balance between height and stability, creating a prominent 3D effect while ensuring durability during the embroidery process.

Embroidery Thread

- Type: Opt for strong, high-quality polyester or rayon threads. Ensure the thread color either complements or contrasts with the foam for visual impact.

- Considerations: Select thread colors that blend with the foam to minimize visibility issues where the foam may show through the stitches.

Fabric

- Material: Ideal fabrics are stable wovens like twill, denim, or canvas, which support the foam well and allow precise stitching without distortion.

- Stability: Choose fabrics robust enough to support the elevated effects of puff embroidery.

Stabilizer

- Purpose: Stabilizers prevent fabric distortion during embroidery, providing essential support to both the fabric and foam.

- Types: Cutaway stabilizers are recommended for their durability and are particularly suitable for use with thicker foams.

Adhesive (Optional)

- Usage: Some foam types come with an adhesive backing, facilitating easier attachment to the fabric before embroidery, ideal for intricate designs or smaller pieces.

Embroidery Machine

- Specifications: A machine that can handle thicker materials and is equipped with specialized digitizing software is crucial for achieving successful 3D puff embroidery. Ensure the machine settings are properly adjusted for foam stitching.

How to do 3D Puffy Foam Embroidery | Step-by-Step Process

Explore the step-by-step essentials of creating vibrant and dynamic 3D puff foam embroidery. Perfect your projects with precision from start to finish!

Step 1: Choose Your Design

Select a 3D puffy foam embroidery designs suitable for 3D embroidery. Simple, bold designs work best because they allow the foam to enhance the depth effectively.

Searching for the perfect design? Visit EMdigitizing! Explore our extensive collection of free puffy foam embroidery designs tailored for vibrant and dynamic results.

And if you’re looking for something uniquely yours, our expert digitizing services can bring your custom designs to life—perfectly matched to your vision!

Step 2: Select the Materials

Choose the right type of foam, thread, and fabric. Use high-density foam, strong polyester or rayon threads, and stable fabrics like twill or canvas.

Step 3: Prepare the Fabric

Secure the fabric in the embroidery hoop ensuring it is taut and stable. This prevents any movement that could distort the stitching.

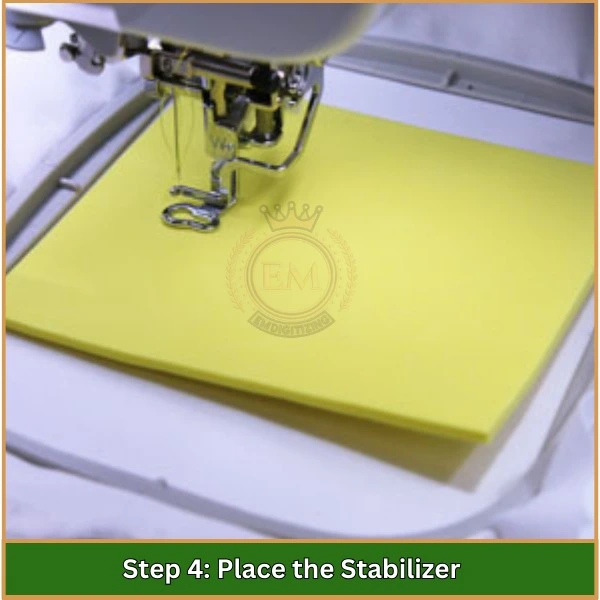

Step 4: Place the Stabilizer

Use a cutaway stabilizer behind the fabric to provide additional support and maintain fabric integrity during the embroidery process.

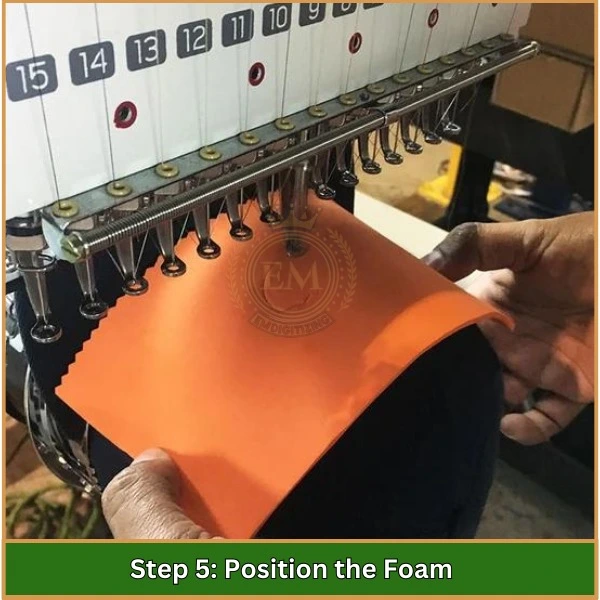

Step 5: Position the Foam

Cut the foam slightly larger than the design area and place it on top of the fabric within the hoop. Ensure it covers all parts of the design that will be embroidered.

Step 6: Start Embroidering

Begin embroidering over the foam. The embroidery machine should be set specifically for puffy foam embroidery fonts, adjusting the needle penetration and stitch density accordingly.

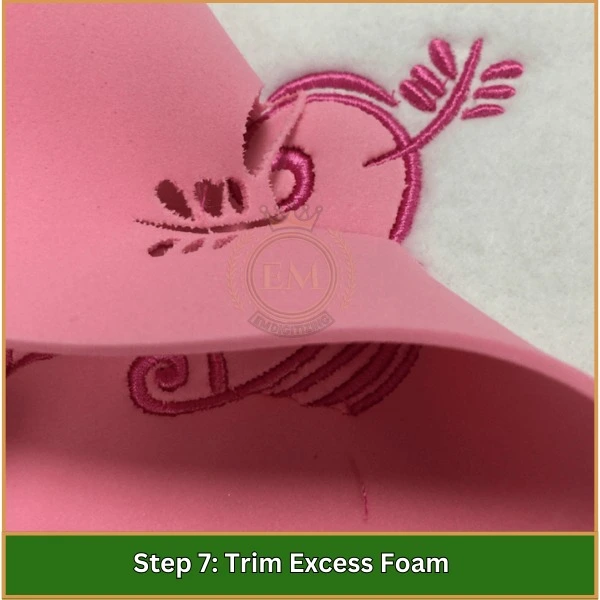

Step 7: Trim Excess Foam

Once the embroidery is complete, carefully remove any excess foam from around the stitches.

This can be done by gently pulling away the foam or using small, sharp scissors to trim close to the stitching.

Step 8: Clean Up

Perform any necessary clean-up around the design to remove small foam particles and ensure a neat finish.

Step 9: Final Inspection

Inspect the embroidered item to ensure the foam has expanded properly and the design appears as expected. Make adjustments to the machine settings if needed for future projects.

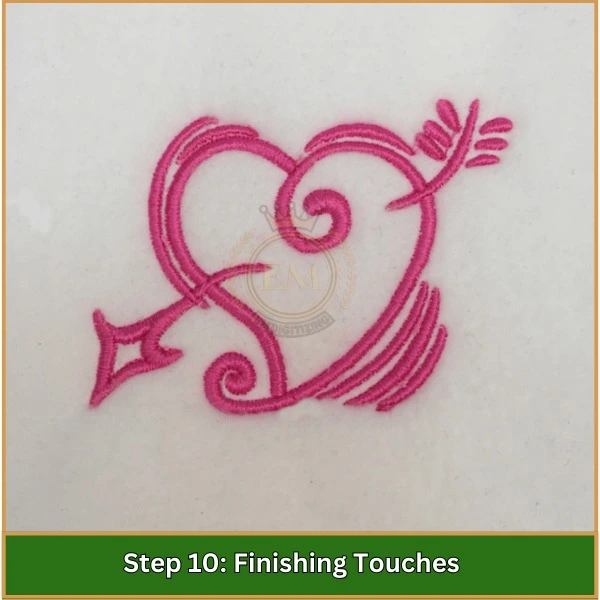

Step 10: Finishing Touches

Apply any finishing touches such as pressing the embroidered item under a cloth to ensure the stitches are set and the foam is not visible.

How to Properly Care for 3D Puffy Foam Embroidery

Taking care of your 3D embroidery is key to preserving its raised effect and overall appearance:

- Gentle Washing: Hand wash or use a delicate machine cycle for your embroidered items. Steer clear of harsh detergents or bleach, as they can weaken the foam and damage the stitches.

- Drying: Always air-dry your embroidered pieces. Using a machine dryer can cause the foam to lose its puffiness or distort the stitches.

- Storage: Store your embroidery flat or gently folded to avoid crushing the foam. Make sure no heavy objects are placed on top of the design to maintain its shape.

- Heat Exposure: When ironing, use low heat and place a cloth over the design to protect the foam and stitches from heat damage.

- Inspection: After washing, inspect your embroidery for any loose stitches or foam issues and address them promptly to keep the design looking its best.

Common Errors to Avoid in 3D Foam Embroidery

- Inadequate stitch coverage: Ensure the design fully covers the foam for a polished, professional look.

- Incorrect foam thickness: Select the correct foam thickness based on your design’s width to ensure proper coverage.

- Improper needle selection: Always use sharp needles suitable for 3D embroidery to pierce through the foam cleanly.

- Neglecting test runs: Perform test runs on scrap fabric to fine-tune stitch density and tension before starting.

- Skipping outline stitches: Always stitch an outline first to secure the foam and stabilize the design area.

- Overcomplicating designs: Stick to simple, bold designs for best results. Relying on expert digitizing for puffy foam embroidery can ensure your design is well-suited for 3D effects.

- Failure to remove excess foam properly: Carefully trim away any excess foam for a neat and clean finish.

Bottom Line

By incorporating 3D puffy foam embroidery into your projects, you can take your designs to the next level, giving them a bold, dimensional look that truly stands out. With the right materials and techniques, your embroidery will pop and create a lasting impression.

If you’re ready to take your designs further, EMDigitizing is here to help with professional digitizing services. We offer fast turnaround times, affordable pricing, and ensure high-quality results every time. Plus, as a new customer, you can enjoy 50% off your first order!

Contact us now to take advantage of this special offer.

FAQs

To embroider with puffy foam, simply place the foam on the fabric before stitching the design, then embroider over it to create raised, dimensional effects.

Puffy foam for embroidery can be purchased online from various retailers specializing in embroidery supplies, as well as from craft stores and sewing shops.

To achieve puffy embroidery, layer puffy foam beneath the fabric, secure it in place with adhesive spray or tape, then embroider the design over the foam to create raised and textured effects.