Embroidery is done on different clothes by embroidery machines to produce beautiful designs. The most important factor is “stitch density” which can help in perfect results of embroidery designs.

It’s not difficult until you know its importance, its definition, its proper use, and when you need to change it.

So, in this article, we’ll discuss all these aspects in detail and help you to get optimal results in your embroidery tasks.

Don’t waste time and let’s jump into the detail.

Machine Embroidery Stitch Density: A Guide to Optimal Settings

What Is Stitch Density And Why Does It Matter?

“The difference in parallel stitches and stitching lines” is referred to as density. In a design, it shows the stitches number per square inch. For appearance and quality of the design, it’s an important aspect.

You can compare it with the image pixel which means the design looks finer and detailed if it has more stitches.

The density of stitches matters for many reasons such as:

1. Durability:

Having a perfect density is the most important factor for durability. An embroidery design that has accurate density can bear wear and tear and also maintain its quality.

2. Visual Impact:

Design must have a professional look that has a great visual impact and doesn’t seem awkward.

3. Fabric Compatibility:

You can change the density of stitches according to your type of fabric. So, you should have a deep understanding of your fabric characteristics, and then density should be maintained according to it so it can control some major issues like puckering.

4. Color Blending:

During the embroidery process, color blending plays an important role. Density difference can affect color transitions which can make a design look poor.

5. Improving Production Efficiency:

Maintained density helps in high production. It lessens the wastage of thread and time for making designs.

What Is Good Stitch Density In Embroidery Design?

We know you want a good medium but don’t want the density of stitches unnecessarily high. Stitch holes are more close if the density is high. Unnecessary high density can destroy embroidery design.

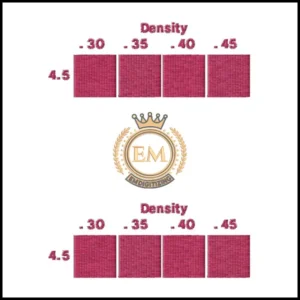

0.4 to 0.45 is a nice density of stitches and is perfect for many designs. But for the right density, there is a need for adjustment, experience, and experiments.

What Does The Stitch Density Number Mean?

Many people get confused because according to them high numbers equals high density but it’s not like that. It is inversely proportional: the higher the number, the lower will be the density.

Generally, density refers to “how much difference is between stitch rows and expressed as stitch per inch (SPI).

Ultimately, if you want to create a less dense design then you need to set rows of stitches far apart from one another.

Our company provides embroidery digitizing services and we have a group of expert digitizers. They keep a close eye on the stitch’s density and set density according to the fabric type. We convert your pattern into a digital embroidery file that contains all the information about optimal stitch density, thread weight and color, stitch direction, stitch type, and much more. So, contact us for a discussion of your density needs.

Setting The Optimal Stitch Density For Your Design:

There are some options for perfect stitch density which are as follows:

- A perfect stitch density for object fills on broadcloth material is 0.4.

- A density of 0.0 to 0.4 is recommended for satin stitches.

- For the starting of most fills, 3.8 points is a typical density. However, it should be adjusted according to fill patterns and applications for various stitch lengths.

For the required appearance, we need to do experiments with various settings of density. By this, cloth damage, breakage of threads, and breaking of needles can be prevented.

While embroidering on delicate cloth, the density of stitches should be elevated for good coverage. While designing a 3D puff design you need high density for coverage of foam.

What Are The Ways To Change The Stitch Density?

Unintentional and precise are two methods by which we can change density. For precise change, digitizing software is needed. It is possible to change the setting manually in every software program, but it may have a different name.

After loading, you can change the density of stitches in the embroidery machine because it gives you access to shrink or stretch the design. Shrinking the design will automatically decrease the density.

A digitizer will be needed to change it. If you change it by yourself it can be difficult for new ones and even experts too.

Do not be afraid!

For embroidery digitizing problems, EMdigitizing has solutions for all. You can contact us to change the density of the stitches. If you don’t have any design, we can digitize it for you according to your required density at flat rates. Our expert can also guide you about maximum density according to the fabric.

Stitch Quality Troubleshooting: Density Isn't Always The Problem:

Many of you may think the quality is not good because of the improper density of stitches. However, the stabilization method can also cause many problems. If enough stabilizer is not applied or it is hooped improperly, it can make the stitch quality worse.

A water-soluble stabilizer or changing the needle of a machine can be helpful for resolving this issue. You must stick to the current density until you try these solutions.

Final Words:

Alright, now you know about stitch density and why it matters. You need practice to get optimal results by setting the correct density of stitches.

At EMdigitizing, we will provide you with all the knowledge so you can achieve remarkable results in your embroidery projects.

If you want embroidery digitizing services you can contact us. We give 50% off to our first-time customers on all available services. At a suitable price, we can digitize your design manually with a fast turnaround.

Thanks for your time. If this article is helpful, you must let your friends know about it.

Happy stitching!

Frequently Asked Questions:

0.4 or 0.45mm is the average stitch density. But you must check the density which is perfect for your design needs and garment.

Tightly packed stitches on small embroidery areas have high density. It makes a design with comprehensive details. It gives a perfect touch to your product.

If accurate and balanced embroidery is done it is defined as high-quality stitching in which stitches are equally arranged. It also clarifies the interest of digitizers.

Polyester or nylon-like threads are considered as strong stitching materials. In many embroidery products, these materials guarantee long-term and high-quality stitching.