Custom PVC patches have become increasingly popular in various industries and sectors due to their durability, versatility, and unique design possibilities. These patches offer a wide range of benefits and applications.

In this article, we will explore everything you need to know about PVC patches, including their benefits, and different types.

Custom PVC Patches Guide – Everything You Should Learn

What are PVC patches?

So, you’ve probably seen those awesome patches on backpacks, jackets, and hats, right? Well, those are PVC patches.

PVC stands for polyvinyl chloride, which is a durable plastic material. These patches are made using a molding process and can be customized with various designs and colors.

Different Types and Styles of Custom PVC Patches

These patches come in various styles let’s discuss PVC patch design options:

2D vs. 3D PVC Patches

When it comes to custom PVC patches, you have the option of choosing between 2D and 3D designs. 2D patches feature flat designs and are typically more budget-friendly.

On the other hand, 3D patches offer a more textured and dynamic appearance, making them visually striking and unique.

Embossed and Debossed PVC Patches

Embossed and debossed PVC patches add depth and texture to your design. Embossing raises the design elements, creating a raised effect, while debossing creates a sunken or indent effect.

These techniques can enhance the overall look and feel of your custom patch, giving it a three-dimensional quality.

Glow-in-the-dark PVC Patches

For a cool and attention-grabbing effect, consider glow-in-the-dark PVC patches.

These patches absorb light and emit a soft glow in the dark, making them ideal for night-time visibility or adding an extra element of fun to your design.

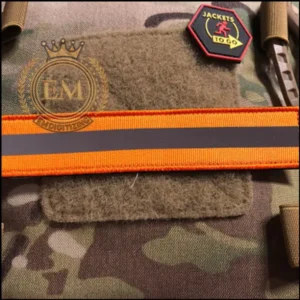

Reflective PVC Patches

Reflective PVC patches are perfect for safety purposes or when visibility is crucial. These patches have reflective properties that bounce light back to its source, making them highly visible even in low-light conditions.

They are commonly used on uniforms, backpacks, or jackets, ensuring that you can be seen from a distance.

Benefits of Custom PVC Patches

Now, let’s discuss the benefits of these patches:

PVC Patch Durability and Longevity

Let’s be real, no one wants a patch that will fall apart after a few wears. PVC patches are built to last. These bad boys are resistant to fading, tearing, and just about any other wear and tear you can think of. So go ahead, and toss them on your favorite jacket or backpack, they can handle it.

PVC Patch Versatility in Design

Personalized PVC patches are like little canvases waiting to be adorned with your wildest imaginings. They can be made in any shape, size, or color you desire. Want a patch shaped like a slice of pizza?

No problem. How about a patch that glows in the dark? You got it. The only limit is your imagination (and maybe the laws of physics).

Weather Resistance

Mother Nature can be a real buzzkill sometimes, but PVC patches couldn’t care less. Rain, snow, or scorching heat – these patches are here to stay.

They are water-resistant, UV-resistant, and can withstand extreme temperature changes without cracking or peeling. It’s like having a patch that’s immune to bad weather vibes.

Low Cost and High Quality

Who says you have to break the bank to rock some killer patches?

PVC patches are not only affordable but also maintain a high level of quality. You get the best of both worlds – a pocket-friendly accessory that doesn’t compromise on durability or style. Talk about a win-win situation.

Choosing the Right Custom PVC Patches Design Supplier

Let’s talk about choosing the right supplier for custom PVC patch manufacturing:

Researching and Evaluating Suppliers

Finding the perfect supplier for your custom PVC patches is like finding a unicorn riding a rainbow – rare and magical. But fear not, EMdigitizing is here.

Start by looking at our websites, and message us for some of our previous patch designs. Pay attention to our range of options, customization capabilities, and overall style. We know you want a supplier who can turn your vision into a reality, not someone who will leave you with a patch that looks like it belongs in a discount bin.

So, don’t be afraid to reach out and ask questions. Inquire about our production process, turnaround time, and any additional services we offer.

We have a solid quality control process so you can expect high-quality design from us.

Pricing and Ordering Process

Let’s face it, we all love a good deal. But when it comes to personalized PVC patches, price shouldn’t be the only determining factor. It’s important to consider the overall value and quality you’re getting.

We offer an affordable pricing structure and also take into account factors like customization options, additional services, and shipping costs. Don’t be afraid to ask for samples or mock-ups to get a better idea of what you’ll be getting.

Additionally, we have a user-friendly ordering process. So go ahead and discuss your needs.

Customer Reviews and Testimonials

Ah, the sweet sound of customer satisfaction. Before making your final decision, take a look at our customer reviews and testimonials. They show how great we are.

Care and Maintenance of PVC Patches

Let’s see how you maintain their integrity:

Cleaning and Washing Guidelines

Taking care of your PVC patches is a breeze. Simply wipe them clean with a damp cloth or sponge for regular maintenance. Avoid using harsh chemicals or abrasive scrubbing, as these can damage the patch.

If your patch is attached to an item that needs washing, such as a jacket or bag, follow the care instructions for that item and avoid machine drying.

Storage and Preservation Tips

When it’s time to put your PVC patches away for a while, make sure to store them properly. Keep them in a cool and dry place, away from direct sunlight, as exposure to extreme heat can cause them to lose their shape or color.

If you want to go the extra mile, you can also store them in a protective sleeve or pouch to prevent any accidental damage.

Handling and Application Recommendations

To ensure the longevity of your PVC patches, handle them with care. Avoid pulling or stretching them excessively, as this can lead to tears or distortions.

When it comes to PVC patch application techniques on fabric, make sure the surface is clean and dry for optimal adhesion.

And remember, if you ever want to remove or reposition your patches, gently peel them off rather than yanking them forcefully.

Conclusion

In conclusion, custom PVC patches are a fantastic way to add personality, style, and branding to various applications. By choosing the EMdigitizing, you have a beautiful patch design.

We offer embroidery digitizing and vector art services that can enhance your business reputation in today’s ever-evolving market.

If you’re a first-time client, we have a special offer just for you! You can get 50% off on all our services and expect the best results. We also provide a free quote, which only takes 5 minutes to generate.

So why wait? Get in touch with us today!

If you found this article helpful, don’t forget to share it with your friends. We also encourage you to share your thoughts with us. We’d love to hear what you think about this topic!

Thanks for reading!

Frequently Asked Questions:

PVC patches are made through a molding process where liquid PVC material is injected into a mold, creating a flexible and durable patch with raised details.

PVC patches are crafted using a soft, rubber-like PVC material that is versatile, weather-resistant, and allows for intricate designs with raised textures.

PVC patches serve various purposes, from branding on uniforms and accessories to expressing personal style on clothing or gear, offering a durable and customizable way to make a statement.

The cost of making PVC patches varies based on factors like size, design complexity, and quantity, with prices typically ranging from a few dollars to several dollars per patch.