10-Reasons-Why Do We Use An Embroidery Hooping Station?

Embroidery is a beautiful form of art that has been around for centuries. It requires precision and patience to create intricate designs on fabrics that can be appreciated for generations. One of the essential tools in embroidery is the embroidery hooping station.

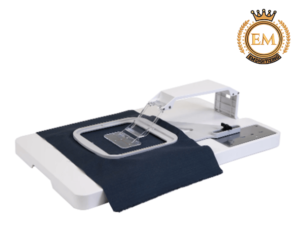

An embroidery hooping station is a specialized workspace designed to make hooping fabric for embroidery easier and more efficient. It typically includes a variety of tools and accessories to help with the hooping process, as well as a dedicated work surface for preparing and hooping the fabric.

Here are some of the components you might find in an embroidery hooping station:

Hoop storage: A designated area for storing embroidery hoops of different sizes and shapes.

Hoop press: An embroidery machine designed to hold the hoop and fabric in place while you stretch and align the fabric for hooping.

Hoop alignment tools: Rulers, templates, or other tools used to ensure that the fabric is centered and straight within the hoop.

Hoop helpers: Clips or clamps used to secure the fabric to the hoop while you work.

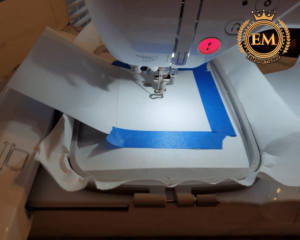

Hoop stabilizers: Materials used to add support and stability to the fabric during the embroidery process, such as tear-away, cut-away, or wash-away stabilizers.

Scissors and cutting tools: Used to trim excess fabric or stabilizer from the hoop after embroidery is complete.

Lighting: Proper lighting is important to ensure that you can see the details of your embroidery work.

By having a dedicated embroidery hooping station, you can streamline your embroidery process and make hooping easier and more efficient. This can help to improve the quality of your work and reduce the time and effort required to complete each project.

Embroidery hooping station has also become a popular tool in the embroidery industry due to its benefits, including time-saving and improving the quality of embroidery. Let’s discuss the top 10 reasons why embroidery hooping stations have become a staple in the embroidery industry.

10-Reasons-Why Do We Use An Embroidery Hooping Station?

Let’s see some of the reasons why do we use an embroidery hooping station:

1. Precise Placement:

One of the main reasons for using an embroidery hooping station is the precise placement of the fabric. It ensures that the embroidery is aligned correctly, ensuring the design looks neat and professional.

2. Time-Saving:

Embroidery hooping stations are known for their time-saving capabilities. They allow for a much faster hooping process than traditional methods, which saves a lot of time, especially when handling bulk orders.

3. Increased Production:

Embroidery hooping stations are a great way to increase production. Since they save time and ensure precision, the embroidery process can be carried out much faster, and a larger number of orders can be processed in less time.

4. Improved Quality:

Using a hooping station can improve the quality of embroidery designs. It allows the fabric to be held securely in place, eliminating any creases, bunches or wrinkles that may result from incorrect hooping.

5. Versatility:

Embroidery hooping stations are versatile and can be used for a wide variety of fabrics, including delicate fabrics such as silk, velvet and organza.

6. Increased Control:

Hooping stations provide increased control over the embroidery process. They offer a better grip on the fabric and can be adjusted to suit the individual’s preference for tension and hold.

7. Durability:

Embroidery hooping stations are built to last. They are made from high-quality materials, ensuring they can withstand the frequent use and handling of different fabrics.

8. Reduced Strain:

Traditional hooping methods can cause strain on the wrist and fingers. Using a hooping station reduces this strain and makes the process more comfortable.

9. Consistency:

The use of embroidery hooping stations ensures consistency in the embroidery process. The embroidery is placed in the exact same position each time, resulting in a uniform and professional finish.

10. Less Waste:

Using a hooping station reduces the amount of waste during the embroidery process. It eliminates the need for re-hooping and ensures that the embroidery is done right the first time.

Winding Up:

Embroidery hooping stations have revolutionized the embroidery industry. They have become an essential tool for embroiderers, saving time, increasing production, and improving the quality of embroidery. Whether it’s for personal use or commercial purposes, a hooping station is a valuable investment for any embroidery enthusiast. It helps create precise and intricate designs while ensuring that the process is comfortable and less time-consuming.

An embroidery hooping station can provide several benefits such as:

Improved efficiency and faster hooping process.

- Organization of all tools and supplies needed in one convenient location.

- Proper lighting to see embroidery details.

- Ability to work with larger embroidery projects.

- Improved embroidery quality by using specialized hooping aids.

A dedicated work surface: This can be a table or desk with enough space to lay out the fabric, hoops, and other supplies.

Proper lighting: Good lighting is important to be able to see the details of the embroidery work and to prevent eye strain.

Storage space: Shelves, drawers, or other storage solutions for embroidery thread, stabilizers, and other supplies.

Hoop press: A machine designed to hold the hoop and fabric in place while you stretch and align the fabric for hooping.

Hoop storage: A designated area for storing embroidery hoops of different sizes and shapes.

Cutting tools: Scissors, rotary cutters, and other cutting tools for trimming excess fabric or stabilizer from the hoop after embroidery is complete.

Hoop alignment tools: Rulers, templates, or other tools used to ensure that the fabric is centered and straight within the hoop.

Hoop stabilizers: Materials used to add support and stability to the fabric during the embroidery process, such as tear-away, cut-away, or wash-away stabilizers.

There are several types of hooping aids available to help with the process of securing fabric in an embroidery hoop. Here are some common types:

Hoop springs: These are metal or plastic springs that attach to the inside of the hoop and provide extra tension to keep the fabric taut.

Hoop helpers: These are small plastic clips that attach to the edges of the hoop and help to keep the fabric in place while you’re working.

Hoop mats: These are silicone or rubber mats that you place over the hoop to help grip the fabric and keep it in place.

Magnetic hoops: These are hoops with magnets that hold the fabric in place, eliminating the need for traditional hooping methods.

Echidna embroidery hooping station is considered one of the best among other systems due to its versatile and customizable features, which allow it to be adapted to the specific needs of the user. The station includes a range of hooping aids such as hoop mats, hoop guards, hoop springs, and clips, which make the hooping process easier and more efficient. Additionally, the station includes built-in storage, lighting, and a dedicated work surface, which provide an organized and comfortable workspace for the user. The Echidna embroidery hooping station is also known for its durability and high-quality construction, which ensures that it will last for years to come.