Choosing the right screen printing inks can make all the difference in how your designs turn out. These inks are specially made to give bright, long-lasting prints on all kinds of surfaces.

Whether you’re working with clothing, accessories, or signs, understanding the types of inks is key to getting great results.

In this guide, we’ll cover the basics of screen silk printing inks, explain their different uses, and help you decide which ink is best for your specific project.

Let’s explore how the right ink can bring your designs to life!

Guide to Screen Printing Inks: Everything You Need to Know

Understanding Screen Printing Ink

It is a special type of ink used in the process of screen printing to transfer designs onto various materials like fabric, paper, or metal. This ink is thicker than regular printing ink, allowing it to create vibrant and durable prints that can withstand washing and handling.

Common Types of Screen Printing Inks

There are various types of printing inks, each offering unique qualities and finishes, making it important to choose the right one based on your project’s needs and fabric type.

- Plastisol ink

- Water-Based ink

- Discharge ink

- Foil Screen ink

- Metallic ink

1. Plastisol Ink

Plastisol is the most commonly used screen print ink in the industry. It is thick, durable, and ideal for printing on various fabrics. Plastisol ink remains on the surface of the fabric, providing vibrant and long-lasting prints. This type of ink is widely used because it doesn’t dry out on the screen, making it easier to work with over extended periods.

Pros:

- Vibrant colors: Plastisol inks produce bright, bold prints that stand out.

- Durability: The prints last longer and are highly resistant to fading, cracking, or peeling.

- Ease of use: This ink is user-friendly and does not dry out quickly, allowing more time to work.

Cons:

- Not breathable: Plastisol can feel heavy on the fabric and doesn’t allow much air to pass through.

- Environmental concerns: Since it is made from PVC, it’s not as eco-friendly as some other types of inks.

2. Water-Based Ink

Water-based ink uses water as the main solvent instead of chemicals, making it a more eco-friendly option. This type of silk screen printing inks soaks into the fabric rather than sitting on top of it, resulting in a softer finish. They are perfect for achieving a natural look, especially on light fabrics.

Pros:

- Soft feel: Water-based inks absorb into the fabric, leaving a lightweight and soft print.

- Eco-friendly: They contain fewer harmful chemicals and are safer for the environment compared to plastisol.

- Ideal for light fabrics: These inks work best on light-colored materials and provide a clean, smooth finish.

Cons:

- Limited on dark fabrics: Water-based inks don’t show up as well on dark fabrics unless mixed with special additives.

- Fast drying: They tend to dry quickly on the screen, which can make them difficult to use for detailed or large designs.

3. Discharge Ink

It works differently from traditional ink screen printing. Instead of adding color to the fabric, it removes the existing dye and replaces it with a new color. This makes discharge ink perfect for printing bright designs on dark fabrics, giving the look of the best silk screen printing inks without layering too much ink.

Pros:

- Soft finish: Like water-based inks, discharge ink results in a soft, breathable print.

- Bright colors on dark fabrics: It provides a vibrant, natural-looking color on dark materials without adding heavy layers of ink.

Cons:

- Complex process: Discharge printing requires more expertise and can be harder to control.

- Chemical smell: This type of ink can produce a strong odor during the printing process.

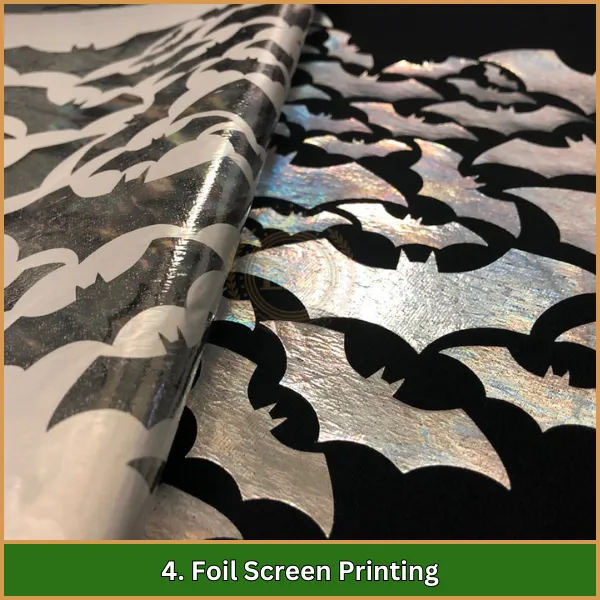

4. Foil Screen Printing

Foil screen printing adds a shiny metallic look to garments by using a thin sheet of foil. The process begins by printing adhesive onto the fabric and then applying the foil over the adhesive. The result is a reflective, shiny finish that gives the design a luxurious look.

Pros:

- Shiny finish: Foil printing provides a striking, metallic look that stands out, making it perfect for special designs.

- Unique appearance: It adds a unique, high-end finish to products, making them more attractive.

Cons:

- Less durable: Foil prints can crack or peel over time, especially with frequent washing or wear.

- Higher cost: It is a more expensive process compared to traditional screen printing inks.

5. Metallic Ink

Metallic ink is made by mixing small metal particles with standard ink, giving it a reflective, shiny appearance. This best screen printing ink is commonly used for creating special effects or decorative prints that need to stand out.

Pros:

- Shiny appearance: Metallic ink adds a glossy, reflective sheen that makes designs eye-catching.

- Durability: Metallic prints tend to last longer and maintain their vibrant appearance.

Cons:

- Thicker ink: The metallic particles make the ink thicker, which can lead to a rougher texture on the fabric.

Limited use: Metallic ink doesn’t work well with all fabric types and may require specific techniques for application.

Factors to Consider When Choosing the Right Screen Printing Inks for Your Project

Choosing the right ink for screen printing involves understanding several key factors to ensure you get the best results for your project. Here are the important aspects to consider:

1. Substrate Type

The type of material you are printing on plays a significant role in selecting the appropriate ink. Fabric screen printing ink like Plastisol works well on cotton and polyester, while water-based inks are ideal for natural fibers such as cotton and silk.

2. Design Requirements

- Color Vibrancy: For bright colors, water-based inks are great for a vibrant finish. For darker fabrics, Plastisol inks provide better coverage and opacity.

- Detail Level: If your design has intricate details, specialty inks like metallic or puff inks may need specific techniques and mesh sizes for best results.

3. Curing Method

Different inks require different curing methods. Plastisol inks cure at lower temperatures, making them suitable for heat-sensitive materials.

Water-based inks, on the other hand, often require higher temperatures and longer curing times.

4. Durability and Longevity

When choosing ink, consider how long the print needs to last. Look for inks that are resistant to UV light, moisture, and wear, especially if the item will be exposed to the elements.

5. Environmental Considerations

If sustainability is important, select inks with low volatile organic compounds (VOCs) or eco-friendly formulations to meet environmental regulations and reduce your carbon footprint.

6. Cost-Effectiveness

Consider not only the price of the ink but also how efficiently it performs. Some inks may have a higher initial cost but will save money in the long run due to lower consumption or reduced waste.

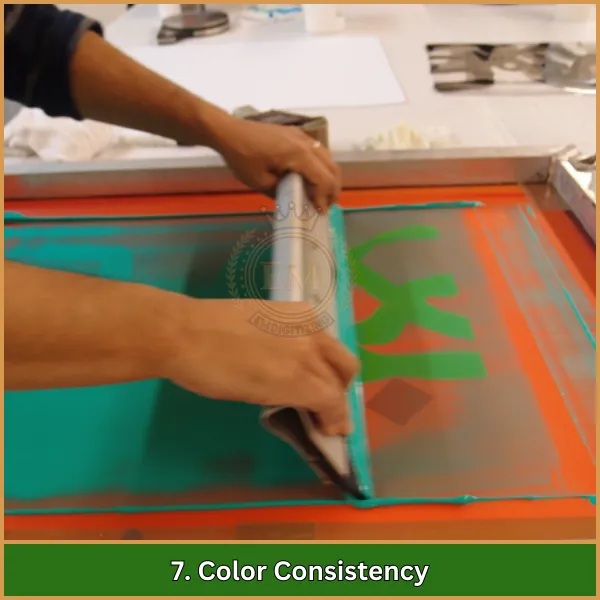

7. Color Consistency

Ensure that the ink provides consistent color throughout print runs. Conduct color-matching tests to ensure the ink works well with your color management system for precise results.

What are the Applications of Screen Printing in Different Industries?

Screen printing is widely used in various industries because of its versatility and ability to produce high-quality prints. Here are the key applications in different sectors:

1. Apparel Industry

- T-Shirts and Clothing: Screen printing is commonly used to customize t-shirts, hoodies, and other garments. Plastisol inks are popular for their durability and vibrant colors, making them perfect for clothing that is frequently washed and worn.

- Promotional Apparel: Companies use screen printing for branded clothing items like uniforms and giveaways because the ink ensures long-lasting and appealing designs.

2. Textile Accessories

- Bags and Caps: Screen printing is used on accessories such as tote bags, caps, and socks, providing consistent quality across different materials.

3. Advertising and Marketing

- Banners and Signage: Screen printing is used to create vibrant banners, flags, and signage for events. The durability of plastisol inks makes them ideal for outdoor use.

- Point-of-Sale Displays: Retailers use screen printing to create attractive displays that grab customer attention and promote products.

4. Home Decor

Textiles: Screen printing is applied to home textiles like curtains, cushions, and tablecloths, allowing for custom designs that enhance home interiors.

5. Industrial Applications

- Safety Clothing: Special functional inks are used in safety apparel to ensure high visibility and meet safety standards, often with reflective properties.

- Product Labels: Screen printing is used for durable labels on industrial products that can withstand harsh conditions.

6. Specialty Products

- Sports Apparel: Specialty inks are used on sportswear to provide flexibility and breathability while maintaining vibrant, long-lasting colors.

- Promotional Items: Inks are applied to items like pens, keychains, and mouse pads for branding and marketing purposes.

7. Packaging

- Food Packaging: Special inks are formulated for packaging materials, ensuring they are safe for food contact while maintaining high-quality prints.

Conclusion

In summary, selecting the right screen printing inks is key to producing high-quality, long-lasting prints. By knowing the various ink types and their applications, you can ensure your designs look vibrant, clear, and professional on any material. The right ink choice will make a big difference in the overall appearance and durability of your prints.

To make your designs even more precise and ready for screen printing, EMdigitizing offers expert vector art services. Our team ensures that your artwork is perfectly prepared for sharp and detailed printing results. Plus, as a first-time customer, you can enjoy a 50% discount on our vector art services. Take advantage of this great offer to enhance your printing projects with top-quality designs!

FAQs

To clean ink off a screen printing screen, scrape off the excess ink, then use a screen wash or emulsion remover made for screen printing. Rinse it well with water to remove any remaining ink.

Yes, you can use printing ink for block printing, but its thickness and drying time might be different from regular block printing inks, which could affect the quality of the print.

Yes, you can layer screen silk printing ink by applying different colors in separate passes. Make sure each layer dries completely before adding the next to prevent color mixing.

Yes, you can paint with printing ink, but it is specifically made for screen printing, so it may not work like traditional paints on different surfaces.