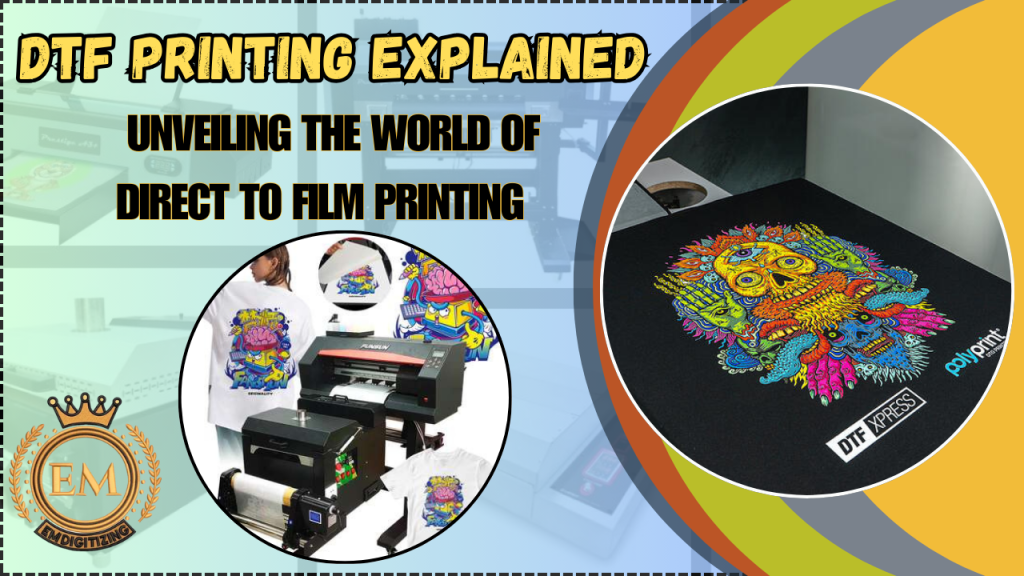

DTF printing, short for Direct to Film printing, is a revolutionary printing method that allows for high-quality and vibrant designs to be transferred directly onto fabrics. This relatively new technique has gained significant popularity in the fashion, apparel, and custom merchandise industries.

It offers numerous benefits such as excellent print quality, versatility in fabric compatibility, and cost efficiency. In this article, we will explore the ins and outs of DTF transfer printing, including how it works, its applications, advantages, and considerations for implementation.

Additionally, we will compare this printing method with other common printing methods, discuss its challenges and limitations, and glimpse into its future prospects as an evolving technology.

DTF Printing Explained | Unveiling The World Of Direct To Film Printing

What is DTF Printing?

So, you’re probably wondering what the heck Direct To Film Printing (DTF) is.

Well, let me break it down for you. DTF stands for “Direct to Film,” and it’s a printing technique that allows you to transfer designs onto various fabrics with ease.

Forget the days of struggling with heat presses and messy inks – this printing is here to save the day!

History of DTF Printing

Now, let’s take a quick trip down memory lane and explore the origin of this printing. This innovative method first emerged in the early 2000s, gaining popularity in the fashion and textile industries.

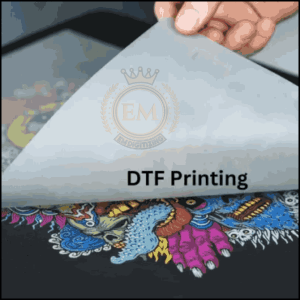

It all started with the development of specialized films that could be printed on and then transferred to fabrics using a heat press. Over the years, it has evolved and improved, becoming a go-to choice for many businesses and individuals looking to bring their designs to life.

How Does DTF Printing Work?

Direct to Film (DTF) printing is a cutting-edge textile printing method that offers a versatile and efficient alternative to traditional printing techniques.

Step-by-Step Process of Direct To Film Printing (DTF)

Okay, let’s get into the nitty-gritty of how this printing actually works. Brace yourself, because it’s about to blow your mind.

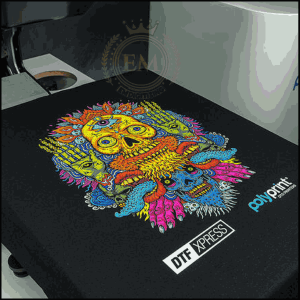

The heat melts the adhesive layer, allowing it to bond with the fabric, while the ink from the film transfers onto the fabric, creating a vibrant and long-lasting print. It’s like magic but without the need for a wand.

Key Components of DTF Printing

Now, you might be wondering what the superheroes behind this printing are. Well, the key components include a DTF printing Machine (obviously), specialized DTF film, a heat press, and an adhesive powder.

These components work together harmoniously to give you the power to create stunning prints on a variety of fabrics. It’s like a well-choreographed dance but without the need for fancy footwork.

Benefits of DTF Printing

Direct to Film (DTF) printing presents a revolutionary approach in the textile printing industry, bringing forth numerous benefits that enhance both the quality and efficiency of fabric printing.

High Print Quality and Vibrancy

One of the greatest perks of Direct To Film Printing (DTF) is the exceptional print quality it delivers. The colors are vibrant, the details are sharp, and the prints can withstand countless washes without fading away like your childhood dreams.

Say goodbye to dull and lackluster prints – it is here to make your designs pop!

Versatility and Compatibility with Various Fabrics

It isn’t picky when it comes to fabrics. It plays well with cotton, polyester, blends, and even stretchy materials.

Whether you’re printing on t-shirts, hoodies, or yoga pants, it has got your back. It’s like having a reliable best friend who’s always up for an adventure.

Cost and Time Efficiency

Time is money, my friend, and Direct To Film Printing (DTF) understands that. Unlike other printing methods, DTF doesn’t require excessive setup or clean-up time.

Plus, you can print multiple designs in a single batch, saving you valuable time and reducing production costs. It’s like having a personal assistant who’s both efficient and cost-effective.

Factors to Consider when Implementing DTF Printing

When implementing Direct to Film (DTF) printing, several key factors should be considered to ensure successful and efficient operation.

Investment and Equipment Requirements

Ready to dive into the world of Direct To Film Printing (DTF)?

There are a few things to consider first. While this DTF shirt printing can be a cost-effective option in the long run, it does require an initial investment in equipment, such as a printer, heat press, and DTF film.

So make sure you crunch those numbers before taking the plunge.

Your bank account will thank you!

Preparation and Pre-treatment of Fabrics

Before you can start printing those fabulous designs, you’ll need to prepare your fabrics. This usually involves applying a pre-treatment solution to ensure that the ink adheres properly.

Think of it like priming a canvas before painting. It’s a crucial step to ensure the best possible print quality.

So don’t skip it, unless you want your designs to look like a preschooler’s finger painting (no judgment if that’s the look you’re going for!).

Understanding Ink and Consumable Options

Ink plays a crucial role in this printing, so it’s important to understand your options. There are different types of inks available, and each has its own unique properties.

Some are more vibrant, while others are better suited for specific fabrics. So do your research, experiment a bit, and find the ink that best suits your needs.

It’s like finding the perfect shade of lipstick – it can make all the difference!

Challenges and Limitations of DTF Printing

While Direct to Film (DTF) printing offers significant advantages in textile customization, it also comes with its own set of challenges and limitations.

Complexity of Color Management

While this offers vibrant colors, achieving consistent and accurate color reproduction can sometimes be a challenge. It’s like trying to paint a masterpiece with a box of crayons – you might not always get the exact shade you’re aiming for.

So be prepared to experiment and fine-tune your color management skills to get the best results.

Limitations in Design Detail and Image Size

While it can produce stunning designs, it does have its limitations when it comes to small, intricate details and large image sizes.

Think of it like trying to fit a majestic unicorn on a postage stamp – it’s just not going to work.

So keep that in mind when planning your designs and choose images that will truly shine in the Direct To Film Printing (DTF) process.

Environmental Considerations

Lastly, let’s talk about the environment. This DTF print, like any printing method, has its environmental impact. The use of inks and consumables can contribute to waste and pollution if not managed properly.

So be mindful of your practices, opt for eco-friendly options whenever possible, and do your part to keep Mother Earth happy. She’ll appreciate it, and so will future generations of fashionistas.

Conclusion

So, there you have it – a crash course in the wonderful world of DTF printing. It’s versatile, efficient, and produces high-quality prints that will knock your socks off (unless you’re printing socks, of course).

Whether you’re a fashion enthusiast, a business owner, or someone who simply wants to add a personal touch to their belongings, Direct To Film Printing (DTF) is definitely worth giving a shot.

Get ready to impress yourself and others with your newfound printing prowess!

EMdigitizing: Embroidery Digitizing Expert At Your Service

If you are interested in any kind of embroidery project, then EMdigitizing is the best option for you. We offer embroidery digitizing and vector art services with a fast turnaround time. You can also visit and check our website as well as our best services.

We also offer a great 50% discount on all our services for our respected first-time clients. We also offer free quotes generated in just 5 minutes.

You should grab this limited-time offer and take your embroidery project to the next level with EMdigitizing.

If you’ve any queries regarding this topic, you can ask them. Thank you for taking the time to read this article.

Frequently Asked Questions:

Direct to Film (DTF) printing is known for its durability and resistance to washing, often lasting as long as the garment itself with proper care.

DTF has advantages over sublimation in terms of versatility, as it can print on a wider range of fabrics and colors, but sublimation might offer better results on specific materials like polyester.

A primary disadvantage of DTF printers is the initial setup cost, which can be higher than other printing methods, and they require specific consumables like DTF inks and films.

DTF can be more cost-effective than screen printing for small to medium runs due to lower setup costs and less labor-intensive processes, but for large volumes, screen printing may be more economical.