15 Best Checklist of Equipment & Supplies Needed to Start Screen Print Shop

In this article, we will provide a comprehensive checklist of equipment and supplies needed to start a screen print shop. Starting a screen print shop can be a lucrative business, but it requires careful planning and investment in the right tools and materials. We’ll cover the essential equipment for screen printing, such as printers, screens, and drying racks, as well as the materials for screen printing, such as inks and emulsion. We’ll also discuss other important factors, such as setting up a proper printshop, finding suppliers like NorCal Screen Print Supply and NorCal Screen Printing Supplies, and starting a printing business from scratch. Whether you’re starting a new screen printing business or expanding an existing one, this checklist will help ensure you have everything you need to succeed.

15 Best Checklist of Equipment & Supplies Needed to Start Screen Print Shop

Checklist of Equipment & Supplies Needed to Start Screen Print Shop

Starting a screen print shop can be a profitable venture, but it requires careful planning and investment in the right equipment and supplies. In this article, we’ll provide a comprehensive list of things needed to start a business, along with useful information about each item and tips for getting started.

Screen Printing Press:

The screen printing press is the foundation of your screen printing operation. It is the machine that holds the screens in place and enables you to print designs on various substrates. There are different types of screen printing presses, including manual, automatic, and semi-automatic models. Depending on your budget and production volume, you can choose the one that fits your needs.

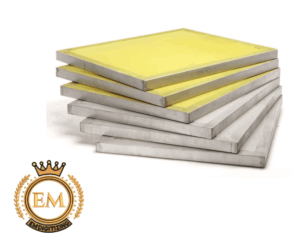

Screens:

Screens are the essential component in screen printing. They come in various mesh counts and sizes, depending on the type of design you want to print. The mesh count is determined by the number of threads per inch, with a higher number indicating a finer mesh. The size of the screen depends on the substrate you are printing on, and the design size. Make sure you have a variety of sizes and mesh counts to accommodate different designs.

Emulsion:

Emulsion is the material that is applied to the screens to create stencils for printing. It is a photosensitive liquid that reacts to light and hardens when exposed to UV light. There are different types of emulsion, including dual-cure, SBQ, and diazo. Choose the type that works best for your printing needs.

Ink:

Ink is the substance that you apply to the substrate to create the design. There are various types of inks available, including water-based, plastisol, and discharge inks. Choose the ink that best suits your printing needs and budget.

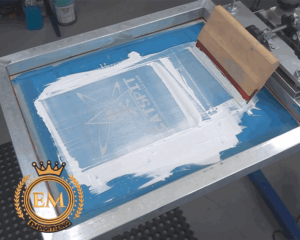

Squeegees:

Squeegees are the tools used to apply ink to the substrate. They come in different sizes and durometers, depending on the type of ink and substrate you are printing on. You’ll need to have a variety of squeegees on hand to accommodate different printing needs.

Flash Dryer:

The flash dryer is a machine used to cure the ink between print layers. It helps to prevent ink bleeding and allows for faster production times. There are different types of flash dryers available, including manual and automatic models.

Conveyor Dryer:

The conveyor dryer is used to cure the ink after the final print layer. It is a necessary piece of equipment for high-volume production. There are different types of conveyor dryers available, including gas and electric models.

Exposure Unit:

The exposure unit is used to expose the emulsion to UV light, which creates the stencil for printing. There are different types of exposure units available, including tabletop and standalone models.

Film Printer:

The film printer is used to print the design onto transparent film, which is then used to create the stencil. There are different types of film printers available, including inkjet and laser models.

Cleaning Supplies:

Cleaning supplies are essential to maintain your equipment and keep your print shop clean. You’ll need a variety of cleaners, including screen cleaners, ink removers, and degreasers.

Shop Tools:

Shop tools are necessary to set up and maintain your equipment. You’ll need a variety of tools, including screwdrivers, wrenches, pliers, and tape measures.

Substrates:

Substrates are the materials that you print your embroidery designs on, such as t-shirts, hats, bags, and posters. Make sure you have a variety of substrates on hand to accommodate different printing needs.

Heat Press:

A heat press is used to apply heat and pressure to transfer designs onto substrates. It is essential for printing on items like hats and bags that cannot be printed on with a screen printing press. There are different types of heat presses available, including clamshell and swing-away models.

Computer and Design Software:

Creating and editing designs require the use of a computer and design software. You can use popular design software to create your designs. You’ll also need a reliable computer to run the software.

Business Supplies:

Business supplies are necessary to run your screen printing business. These include items like business cards, invoices, receipts, and shipping materials. Make sure you have a system in place for managing your orders and finances.

In addition to these essential items, there are other things you’ll need to consider when starting a screen print shop. You’ll need to research the market and competition, set up a website and social media presence, and develop a marketing strategy. You’ll also need to obtain the necessary licenses and permits, register your business, and obtain insurance.

Tips To Start Screen Print Shop

Starting a screen print shop requires careful planning and preparation. Here are some tips to help you start your screen printing shop:

Develop a Business Plan:

A business plan is very important for any new venture. It will help you identify your target market, competition, and marketing strategy. It will also help you determine your startup costs and funding needs. A well-written business plan can help you secure financing and guide your decision-making as you grow your business.

Research the Market:

Before starting your screen print shop, it’s important to research the market and competition. Look at other screen printing businesses in your area and assess their strengths and weaknesses. Identify gaps in the market that you can fill and determine how you can differentiate yourself from the competition.

Choose the Right Equipment:

Invest in quality equipment that can handle the volume and type of printing you plan to do. Don’t skimp on essential items like a screen printing press, exposure unit, and flash dryer. Research different brands and read reviews before making your purchase.

Build a Strong Brand:

Your brand is what sets you apart from the competition. Develop a strong brand identity, including a logo, website, and social media presence. Use consistent branding across all of your marketing materials to build brand recognition.

Develop a Marketing Strategy:

Marketing is essential for attracting new customers and building your business. Develop a marketing strategy that includes both online and offline tactics. Consider offering promotions, hosting events, and partnering with local businesses to expand your reach.

Focus on Customer Service:

Customer service is key to building a loyal customer base. Respond promptly to customer inquiries, deliver orders on time, and go above and beyond to meet your customers’ needs. Positive word-of-mouth referrals can be a powerful tool for growing your business.

Learn from Experts:

Join a screen printing association or attend industry conferences to learn from experienced screen printers. Take advantage of online resources, like forums and blogs, to stay up-to-date on industry trends and best practices.

Starting a screen print shop can be a challenging but rewarding venture. By following these tips and investing in the right equipment and supplies, you can build a successful screen printing operation.

Conclusion:

Starting a screen print shop can be a challenging but rewarding venture. By investing in the right equipment and supplies and following best practices for running a business, you can build a successful screen printing operation. Make sure to research your options and seek advice from experienced screen printers to help you get started.

If you want to customize embroidery logo digitizing, EM DIGITIZING will be your best choice. At EM DIGITIZING, we deliver the best embroidery logo digitizing services with the best quality. We offer 50% off on all our services to our potential customers on their first order. So, get a free quote now and we will get in touch with you.

Hope this article will be helpful for you guys!

If there’s any question related to this article feel free to comment to us. And, thanks for reading!

The cost of making a screen print screen can vary depending on the size and type of screen. A basic 20×24 inch screen can cost around $20 to $30 to make, while larger screens or specialized screens can cost more.

A screen printing workshop is a space where screen printing is taught, practiced, or facilitated. These workshops can be open to the public or private and can range in size from small independent studios to large commercial facilities.

Screen printing and vinyl printing are two different printing methods that each have their own advantages and disadvantages. Screen printing is generally better for larger quantities and more detailed designs, while vinyl printing is better for smaller runs and simpler designs

The cost of screen printing can be influenced by several factors, such as the number of colors in the design, the complexity of the design, and the size of the print run. Additionally, the cost of materials, such as ink and screens, can also contribute to the overall expense.

Yes, screen printing can be a profitable business with the right approach. Factors such as market demand, pricing strategy, and cost management can all impact the profitability of a screen printing business. Building a strong brand and providing excellent customer service can also contribute to long-term success.