10 Most Common Embroidery Machines Problems & Solutions

Introduction:

Embroidery is when you sew a design or pattern onto a cloth by hand with a needle and thread. Machine embroidery is when you do the same thing but with a machine, which makes it faster and easier. Despite the convenience, sometimes things can go wrong with the machine.

As a professional sewer, you know that if your embroidery machine is not working properly, it can ruin your design and you’ll be unhappy with the final result. To avoid this, here are 10 common embroidery machine problems and how to fix them.

10 Common Embroidery Machine Problems

Embroidery digitizing may seem simple, but it actually involves a lot of work with stitches, machines, and software. There can be problems with both the stitches and the machine, so it’s important to know about these problems to avoid them. Let’s take a look at these issues.

1. Problems with the thread:

One of the most common problems in embroidery is thread. No matter how careful you are, thread problems will happen. To keep your work going smoothly and keep your customers happy, it’s important to fix thread problems right away.

Examples of thread problems are fraying, balling, breaking, and tangling. These problems often happen because the tension is not set correctly. The good news is that these problems can be easily fixed by making some small adjustments. This will help you avoid wasting time and losing money.

2. There’s a lot of noise from the machine:

A common embroidery machine problem is that they can make noise while in use. This can happen for several reasons, such as needing to be cleaned, oiled, or having a damaged or dull needle.

To avoid noise problems, it’s important to take good care of your machine by cleaning and oiling it regularly and having it serviced when necessary. Also, make sure the feed teeth and other parts are clean and that the needle is in good working condition. If the needle is not good, replace it with a new one.

3. Breaking of Needle:

Breaking needles is a common problem in embroidery machines. This can happen when the needle is bent, loose, too small, or the stitch doesn’t fit the fabric properly.

The easiest solution to this problem is to simply replace the needle with a new one. Make sure to use the correct size of needle and stitch type for the fabric you are working with. Also, adjust the position of the needle and use the right presser foot for the stitch you are using.

4. Skipped stitches:

Another common problem with embroidery thread is when it doesn’t start properly or skips stitches during a pattern. To avoid these issues, you need to have the right equipment, materials, and proper setup.

To solve false starts, check the back of the design for the balance of the top thread and bobbin thread. If you can only see a few strands of bobbin thread, then either the bobbin is too tight or the top tension is too loose. The bobbin should drop about 1 to 12 inches when it’s in the right balance.

If the bobbin drop test is good, tighten the top tension by adjusting the small and big tension knobs. Also, check to make sure the thread is properly threaded through the machine.

5. Fraying:

A common problem with embroidery thread is when it starts to fray. To fix this, you should check your needle first. Make sure you are using the right size and type of needle for your machine. Some machines use round shank needles, while others use flat shank needles.

If the needle is too small for the thread, it can cause too much friction, which can cause fraying. You should also replace your needles after about 8 hours of use, instead of waiting for them to break. The tension of the thread might also be too high, causing fraying. And if the cone holding the thread is damaged, this can also cause issues, so replacing the cone can help fix this problem.

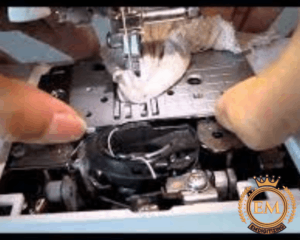

6. Jamming:

Sometimes, the embroidery machine can get stuck and not work properly. This is called jamming. To fix this, you need to take apart the machine carefully and look for the problem. Make sure to be careful and ask for help if you’re not sure what to do. You might also need to oil some parts of the machine to make sure it runs smoothly. After fixing the problem, test the machine to make sure it’s working properly.

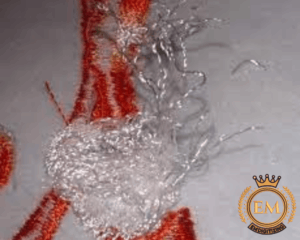

7. Birdnesting:

Birdnesting is when a thread gets tangled up and looks like a bird’s nest between the needle plate and the fabric. It happens when the top thread tension is not right, which stops the fabric from moving smoothly. To fix this, you need to check and adjust the top thread tension to make it right, and also make sure both the top and bottom thread tensions are balanced. Using the correct hoops to hold the fabric tightly without any gaps between the sewing arm and the hoop is also important.

8. Bobbin issues:

If your embroidery machine is having trouble with the bobbin, there are a few things you can try to fix it. First, turn the knob that controls the tension of the bobbin. If that doesn’t help, check your machine’s manual for instructions on how to increase the number of stitches per inch. Also, make sure the bobbin is threaded properly. To avoid this problem, use high-quality bobbins.

9. Thread Build-Up:

Thread Build-Up is a common problem that happens when there is too much thread behind the needle or on the neck plate. This can cause the thread to form balls or clumps. To fix this issue, check if the thread has been properly threaded through the tension bars. Make sure the bobbin is in the right place and that there is no slack in the thread. Also, check that the top and bottom tensions are balanced, not too tight or too loose. Finally, make sure the thread is not tangled with the bobbin or hook.

10. Puckering:

Puckering is a problem that can happen when your embroidery pattern is not lying flat on the fabric and looks bunched up. This usually happens when the fabric is taken off the machine after stitching. Puckering can be caused by several things, such as using the wrong stabilizer, hooping the fabric incorrectly, or having too tight thread tension. To avoid puckering, it’s important to use the right stabilizer for the fabric you’re working with, hoop the fabric correctly, and have the correct thread tension. As you keep using your embroidery machine, you’ll learn more about how different fabrics react and how to prevent puckering.

Closing Line:

So, these were the common Embroidery machines issues that could be fixed easily. If you can’t solve the problem, it’s best to ask a professional for help. To keep your embroidery machine working well, have a trained person check it once a year. Also, clean it regularly, change the needle often, and use good quality thread. When you’re not using the machine, cover it with a cloth to protect it from dust.

We hope you enjoyed reading this article as we did in writing.

If you want to customize embroidery logo digitizing, EM DIGITIZING will be your best choice. At EM DIGITIZING, we deliver the best embroidery logo digitizing services with the best quality. We offer 50% off on all our services to our potential customers on their first order. So, get a free quote now and we will get in touch with you.

Hope this article will be helpful for you guys!

If there’s any question related to this article feel free to comment to us. And, thanks for reading!