Using metallic ink in screen printing can instantly elevate the look of your designs, giving them a bright, reflective finish. It’s an easy way to add a touch of elegance or make your prints more noticeable. Whether you’re creating custom apparel, posters, or product labels, these inks bring a unique shine that regular inks simply can’t match.

In this article, we’ll take a closer look at the main reasons why incorporating metallic screen printing inks into your screen printing projects can make a big difference.

Why Metallic Inks Are Great for Screen Printing

What Are Metallic Inks?

They are special inks that create a shiny, reflective look when printed. They have tiny metallic particles or pigments that make the surface sparkle. These inks are often used to make designs stand out with a bright and attention-grabbing finish. You can find them in colors like gold, silver, and other metallic tones, giving your prints a rich and elegant appearance.

Types of Metallic Printing Inks

There are several different kinds of shimmering inks, each providing unique effects. Here are the main categories:

1. Metallic Pigment-Based Inks

These inks contain metal particles such as aluminum, bronze, or copper, giving a strong, reflective metallic shine.

- Pros:

- Provides a bold, striking metallic effect.

- Highly reflective and great for luxury designs.

- Available in popular shades like gold, silver, and copper.

- Cons:

- Can be difficult to print on porous surfaces due to ink absorption.

- Prone to oxidation over time, which can dull the shine.

- Requires specific techniques for even coverage.

2. Pearlescent Inks

These inks use mica or pearl-like pigments while using a metallic ink printer to create a soft, shimmery finish that is more delicate than traditional metallic printing inks.

- Pros:

- Offers a subtle, elegant glow, perfect for softer designs.

- Less reflective, making it ideal for understated projects.

- Available in a variety of colors beyond metallic shades.

- Cons:

- Lacks the strong shine of metallic pigment-based inks.

- May not be as visually impactful in low-light conditions.

- Requires careful application to avoid uneven finish.

3. Foil-Like Inks

Foil-like inks mimic the look of metallic foil, offering a high-gloss, mirror-like finish.

- Pros:

- Provides a smooth, ultra-shiny finish.

- Highly reflective, similar to actual metallic foil.

- Ideal for designs that require a premium or luxurious feel.

- Cons:

- More expensive compared to other ink types.

- Can be challenging to achieve a consistent finish.

- Requires special techniques for proper application.

4. Chrome Inks

Chrome inks are designed to give a highly reflective, mirror-like appearance, similar to polished chrome.

- Pros:

- Offers a sleek, polished, mirror-like finish.

- Extremely reflective, perfect for eye-catching designs.

- Works well for modern, high-tech visuals.

- Cons:

- Difficult to apply evenly.

- Requires specific curing processes to maintain the reflective quality.

- Prone to scratching and damage if not applied correctly.

5. Glitter Inks

These inks contain small reflective particles or glitter to create a sparkling, fun finish.

- Pros:

- Adds a vibrant, playful sparkle to designs.

- Great for colorful, festive, or attention-grabbing prints.

- Available in a wide range of colors and glitter sizes.

- Cons:

- Glitter particles can clog printer nozzles or screens.

- May feel rough to the touch, depending on the amount of glitter used.

- Can lose some shine over time, especially with excessive handling.

6. Iridescent Inks

Iridescent inks shift color depending on the angle of the light and the viewing position, creating a dynamic rainbow-like effect.

- Pros:

- Offers a unique, color-shifting effect that changes with light.

- Creates a visually dynamic and engaging design.

- Works well for eye-catching and creative projects.

- Cons:

- Requires careful application for the full effect.

- Not as bold as metallic or glitter inks in terms of reflectivity.

- Can be more expensive and harder to source.

Key Benefits of Using Metallic Inks in Screen Printing

Incorporating shimmering and reflective inks into your screen printing projects can significantly enhance the final look. These types of inks provide not only visual appeal but also durability and versatility across a range of materials.

- Luxurious and Premium Look

- Enhanced Visual Appeal

- Versatility Across Various Materials

- Unique Texture and Finish

- High Durability

Let’s dive into the detailed benefits.

1. Luxurious and Premium Look

Using these inks instantly adds a sense of luxury to your designs. The glossy, reflective finish creates an upscale feel that elevates the appearance of printed items. This luxurious effect is particularly appealing for high-end products like invitations, packaging, and branded merchandise. By giving your prints a polished, professional look, these inks help convey quality and exclusivity.

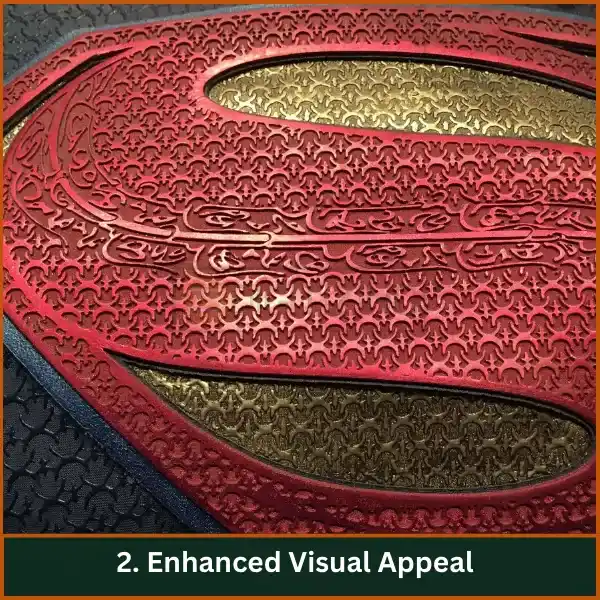

2. Enhanced Visual Appeal

The reflective quality of these inks makes them stand out from ordinary prints. As they catch and reflect light, the shimmering effect draws immediate attention to the design, making it visually striking.

This enhanced appeal is especially valuable in marketing materials, where grabbing attention is key. Whether on clothing, posters, or promotional items, the shine adds a captivating element to any project.

3. Versatility Across Various Materials

One of the major advantages of these screen printing metallic inks is their ability to adhere to a wide variety of surfaces.

From fabrics like cotton and polyester to non-porous materials such as plastic and paper, these inks work seamlessly across different textures.

This versatility makes them suitable for numerous applications, from apparel and accessories to packaging and promotional items, providing a consistent quality across different mediums.

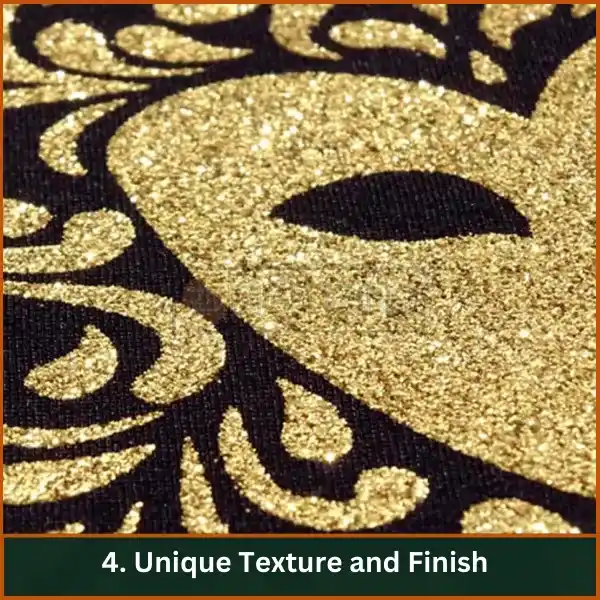

4. Unique Texture and Finish

Unlike traditional inks, shimmering options offer a unique tactile experience. The slight raised texture gives a smooth and luxurious feel, adding to the overall uniqueness of the print. This texture not only enhances the visual aspect but also creates a sensory experience for anyone interacting with the product. The added dimension makes it perfect for special projects where the finish plays a crucial role in making the design memorable.

5. High Durability

The longevity of these reflective inks is another standout benefit. The metal particles provide additional strength, making the print more resistant to fading, peeling, or wearing off. This high durability is especially important for items like promotional materials or clothing, which often endure heavy use or outdoor exposure. The ability to maintain brightness and quality over time ensures the design stays intact and impressive for much longer.

Bottom Line

Metallic ink brings a whole new dimension to screen printing, giving your designs that extra sparkle and shine. It helps make your prints more striking, durable, and visually appealing. Whether you’re after a luxurious look or something more subtle, metallic inks printing can make all the difference in creating memorable designs that stand out.

To take your designs even further, check out our vector art services at EMdigitizing. We provide high-quality vector files that are ideal for screen printing. You’ll benefit from our fast turnaround time and affordable pricing, ensuring your project is ready on time and within budget. Plus, as a special offer, we’re giving 50% off to first-time customers. Let us help you bring your creative ideas to life with precision and style!

FAQs

To print with metallic ink, use a screen printing process with metallic ink specifically formulated for the substrate, ensuring compatibility and proper curing.

To remove printed ink from metal, apply a solvent or chemical remover suitable for the ink type and metal, following safety precautions and environmental guidelines.

Yes, metallic ink can be printed, typically through screen printing or offset printing, using special inks that contain metallic particles.

Printing metallic ink at home involves using metallic ink cartridges with compatible inkjet printers or applying metallic foil with a laser printer and a laminator for a metallic effect.