Want to learn how to do T-shirt screen printing at home? This guide will show you how!

Screen print transfers at home are a great way to make your own unique T-shirts. We’ll walk you through each step, from picking the right materials to actually printing your design. This guide is perfect for beginners and anyone who wants to get creative with their clothes.

Follow along, and you’ll be making your own cool T-shirts in no time!

How to Do T-Shirt Screen Printing at Home | Detailed Guide

Materials Needed for Screen Printing at Home

Here’s a list of everything you’ll need to start at home silk screen printing. Gather these materials and you’re ready to begin:

Screen and Frame: Pick a screen with a mesh count between 110 and 160. This size works well for most projects. Frames can be made of wood or aluminum and aluminum lasts longer.

Photo Emulsion and Sensitizer: Choose a dual-cure emulsion. It’s easier to use, especially if you’re just starting out. Ensure the sensitizer is compatible with the emulsion type you choose.

Squeegee: A 70-durometer squeegee is recommended for most fabric screen printing tasks. It’s stiff enough to push ink through the screen but flexible enough to give a smooth finish.

Ink: Water-based inks are great for beginners. They are easy to clean up and good for the environment.

They look best on light-colored fabrics. If you’re working with dark fabrics, use plastisol ink for brighter colors.

Transparency Film: Make sure the transparency film is clear and fits your printer type (inkjet or laser).

It should be made for screen printing so it blocks light properly when you’re exposing your design.

Lamp: A 250-watt bulb should work well. It needs to emit UV light, which helps the photo emulsion harden correctly.

These materials are essential for setting up at home screen printing t shirt workspace, allowing you to transfer your designs onto T-shirts effectively.

T-Shirt Screen Printing At Home in 9 Easy Steps

Now that you’ve gathered all the necessary materials, it’s time to start the screen printing process!

Step 1: Create Your Design

Start by designing your artwork. It’s best to keep it simple, especially for your first print. Use graphic design software or print your design onto a transparent acetate film. Ensure the design has clear edges and is suitable for screen printing.

If you already have a design but it’s not high quality, you can contact us at EMdigitizing. We can vectorize your design, ensuring that no matter how much you enlarge it, the pixels won’t distort, and your end results will look great.

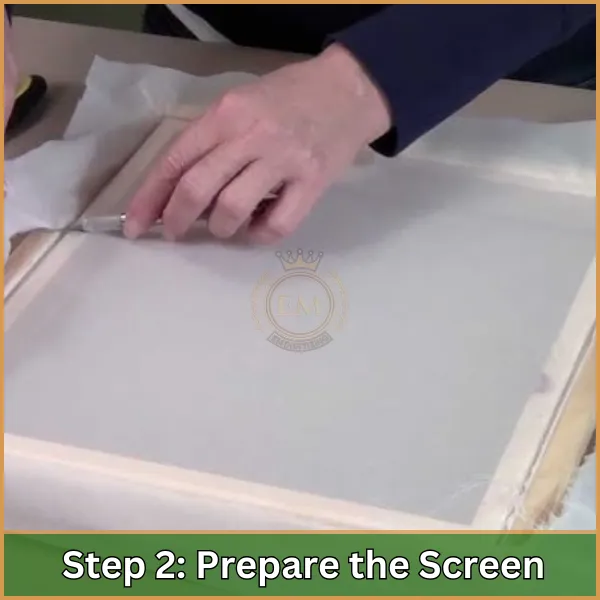

Step 2: Prepare the Screen

Select a mesh screen appropriate for your design’s complexity and the fabric texture. Coat the screen with a light-reactive emulsion using a squeegee. Ensure an even layer to create a good stencil.

Step 3: Expose the Emulsion

Once the emulsion has dried completely, place your acetate sheet with the design on the screen.

Expose the screen to bright light (like a 150-watt bulb) for the time specified by your emulsion instructions.

This process hardens the emulsion where the light hits, leaving the areas covered by your design unhardened.

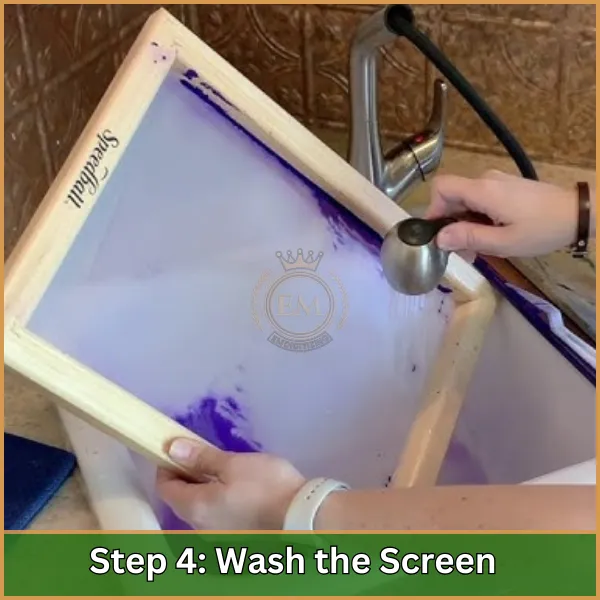

Step 4: Wash the Screen

After exposure, carefully rinse the screen with lukewarm water. The unhardened emulsion will wash away, revealing your stencil. Allow the screen to dry completely.

Step 5: Prepare the Fabric for Printing

Lay your blank t-shirt flat on a printing board or surface. Ensure it is wrinkle-free for an even print. If using a printing press, secure the shirt to the platen.

Step 6: Ink Application

Position the screen over the t-shirt. Apply ink at the top of the screen and use a squeegee to pull the ink across the stencil. This forces the ink through the open areas of the screen onto the fabric below.

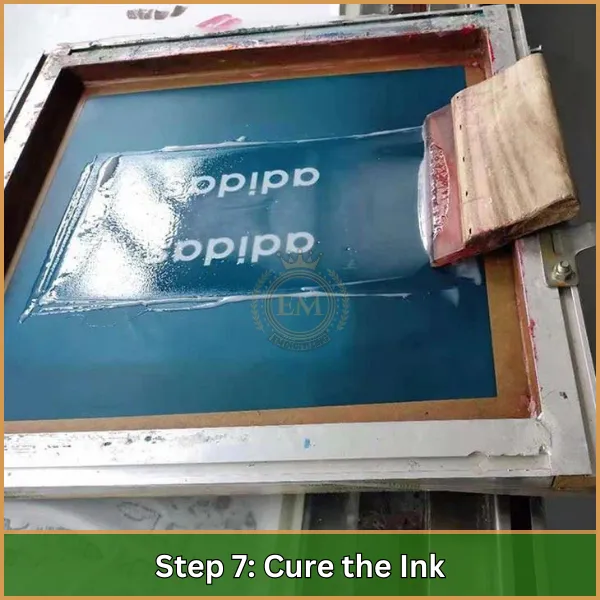

Step 7: Cure the Ink

For inks to last, they need to be cured after printing. You can use a heat press, conveyor dryer, or an oven, depending on your setup. Follow the ink manufacturer’s instructions for the appropriate curing temperature and time.

Step 8: Clean Up

Once the printing is complete, clean the screen and tools with water to remove any remaining ink and emulsion. It is important to clean your equipment properly to extend its life.

Step 9: Quality Check

Inspect the printed t-shirt for any imperfections. If necessary, wash the shirt to remove any residue and ensure the print adheres well.

What are the Benefits of Screen Printing at Home?

Screen silk printing at home offers several benefits that make it an appealing choice for hobbyists, artists, and entrepreneurs alike:

- Cost-Effective: Once you invest in the basic equipment, screen printing can be quite cost-effective, especially when producing designs in bulk. It eliminates the need to pay for professional printing services.

- Customization: You have complete creative control over your designs, allowing you to experiment with different colors, patterns, and materials. This is ideal for creating personalized items or unique merchandise.

- Flexibility: Screen printing at home allows you to print on a variety of surfaces including textiles, ceramics, wood, paper, glass, and metal. This flexibility can expand the range of your projects or products.

- Quality and Durability: Screen-printed designs are known for their durability and high quality, especially when properly cured. The inks used are typically more robust than those in digital printing, resulting in prints that can withstand wear and washing better.

- Potential for Business: For those looking to start a small business, screen printing at home can be turned into a profitable venture. The ability to produce in small batches allows for low startup costs and the capacity to offer custom products.

- Environmental Control: When printing at home, you can choose to use environmentally friendly inks and materials, helping to reduce the environmental impact compared to some commercial printing processes.

These benefits highlight the practical and economic advantages of adopting screen printing as a home-based activity or business.

Bottom Line: Ready to Start Screen Printing at Home!

Now that you have set up your screen printing machine, you will need high-quality images to achieve the best results. For this, consider getting your images vectorized.

We offer vector art services at affordable prices with a fast turnaround time. Plus, if you are ordering from us for the first time, you’ll receive a 50% discount.

So don’t wait, place your order today and take your t-shirt designs to the next level!

Thank you for taking the time to read this article.

Frequently Asked Questions:

Screen printing can be profitable, especially for high-volume orders, due to its low cost per unit and ability to produce durable, vibrant designs.

T-shirt printing is a profitable business with a high demand for custom designs, but success depends on creativity, marketing, and efficient production methods.

The best printer for T-shirt printing is often a direct-to-garment (DTG) printer, which offers high-quality, detailed prints and is suitable for small to medium batch sizes.