oben 8 Arten von Siebdruckverfahren in 2023

Einführung:

Screen printing has long been a popular method for transferring designs onto various surfaces, from textiles to paper and plastics. As technology advances, new screen printing processes emerge, offering enhanced capabilities and efficiency. In diesem Artikel, we will delve into the top different 8 types of screen printing processes that are making waves in 2023, showcasing their unique features and applications.

oben 8 Arten von Siebdruckverfahren in 2023

8 Types of Screen Printing Processes In 2023

Let’s see the top 8 screen print types processes in 2023:

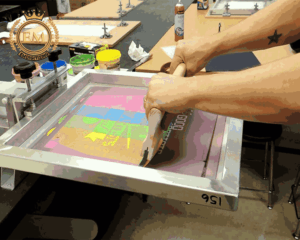

Traditional Screen Printing:

Also known as flatbed screen printing, this is the classic method that involves a mesh screen, a stencil, and a squeegee. Ink is pushed through the stencil onto the substrate, Erstellen des gewünschten Designs. Traditional screen printing in art remains a reliable choice for large-scale production and offers excellent color vibrancy and durability.

Water-Based Screen Printing

Water-based screen printing utilizes water-based inks instead of traditional solvent-based inks. This method offers several advantages, including eco-friendliness, soft and breathable prints, and the ability to achieve a wide range of colors. Water-based Siebdruck methods are particularly popular in the fashion industry, where sustainability and comfort are highly valued.

Discharge Screen Printing:

Discharge screen printing involves using a specialized ink that removes the dye from the fabric, resulting in a bleached effect. This technique is commonly used on dark-colored garments and produces soft, vintage-like prints. Discharge printing techniques offers a unique aesthetic appeal and is favored in the fashion and streetwear industries.

Plastisol Screen Printing:

Plastisol screen printing employs a thick, plastic-based ink that sits on top of the fabric rather than penetrating it. This types of printing in art method is known for its vibrant colors, Opazität, and longevity. Plastisol prints retain their vividness and durability even after numerous washes, making them suitable for apparel, promotional items, and outdoor signage.

Simulated Process Screen Printing:

Simulated process screen printing is specifically designed for reproducing highly detailed, photorealistic images with a wide range of colors. By utilizing halftones and blending techniques, this method achieves smooth gradients and subtle shades. It is often used for printing on T-shirts, Poster, and other merchandise requiring high-quality image replication.

High-Density Screen Printing:

High-density screen printing creates raised or textured effects by applying a thick layer of ink to the substrate. This types of art printing technique adds depth and dimension to the design, resulting in a tactile and visually appealing outcome. High-density prints are popular in sportswear, branding, and promotional products.

Foil Screen Printing:

Foil screen printing involves applying a layer of metallic foil onto the Stickerei-Design, creating a shiny, reflective effect. The foil is transferred using heat and pressure, resulting in a striking and luxurious finish. Foil screen printing ideas are commonly used for adding accents, Logos, or embellishments to high-end apparel, Einladungen, and packaging.

All-Over Screen Printing:

All-over screen printing, also known as jumbo screen printing, allows for printing across the entire surface of a garment or substrate. This method utilizes oversized screens and specialized equipment to achieve seamless and continuous designs. All-over printing is particularly popular in the fashion industry for creating bold and eye-catching apparel.

Tips To Improve Your Screen Printing Process

Here are some tips to improve your screen printing process:

Ensure that your artwork is high-quality, properly sized, and optimized for screen printing. Use vector graphics or high-resolution images to achieve sharp and crisp prints.

The screen mesh determines the level of detail you can achieve. Select a mesh count appropriate for your design. Higher mesh counts are ideal for intricate designs, while lower mesh counts are suitable for bold and larger designs.

Coat your screens evenly with emulsion and allow them to dry in a controlled environment. Befolgen Sie die empfohlenen Belichtungszeiten, um die gewünschte Schablonenhärte zu erreichen.

Investieren Sie in hochwertige Tinten, die speziell für den Siebdruck entwickelt wurden. Erwägen Sie die Verwendung von Zusatzstoffen wie Extendern oder Reduziermitteln, um die gewünschte Tintenkonsistenz und -leistung zu erreichen.

Stellen Sie sicher, dass Ihre Tinte richtig gemischt ist und die richtige Konsistenz hat. Zu dicke oder zu dünne Tinte kann zu Druckproblemen führen. Testen Sie Ihre Tinte auf Stoffresten, bevor Sie mit der Produktion beginnen.

Überprüfen und kalibrieren Sie Ihre Druckgeräte regelmäßig, einschließlich der Bildschirmspannung, Rakeldruck, und Abstand ohne Kontakt. Eine ordnungsgemäß gewartete Ausrüstung gewährleistet konsistente und genaue Ausdrucke.

Vor dem Druck auf das Endprodukt, Führen Sie Testdrucke durch, um mögliche Probleme oder erforderliche Anpassungen festzustellen. Perform quality control checks throughout the production run to maintain consistency and identify any defects.

Follow the manufacturer’;s guidelines for curing the prints. Ensure that the ink is fully cured to achieve maximum durability and wash resistance. Use proper curing equipment, such as a heat press or conveyor dryer, to achieve consistent and reliable results.

Clean your screens and tools after each use to prevent ink buildup and clogging. Proper maintenance extends the lifespan of your screens and ensures consistent print quality.

Don’;t be afraid to experiment with different techniques, Tinten, and substrates. Learn from your printing experiences, make adjustments as needed, and continue to refine your process.

Stellen Sie sicher, dass Ihr Druckbereich sauber und frei von Staub oder Ablagerungen ist, die die Druckqualität beeinträchtigen könnten. Richten Sie Ihre Siebe richtig aus und befestigen Sie sie an der Druckmaschine, um eine genaue Ausrichtung zu gewährleisten. Verwenden Sie Passmarken oder ein Registrierungssystem, um eine präzise Ausrichtung zwischen Farben oder Schichten zu erreichen.

Nehmen Sie sich Zeit, Ihre Tintenfarben richtig zu mischen und aufeinander abzustimmen, um die gewünschten Farbtöne und Töne zu erzielen. Notieren Sie sich Ihre Tintenmischungsverhältnisse, um bei zukünftigen Druckläufen eine konsistente Farbwiedergabe zu gewährleisten. Führen Sie bei Bedarf Farbtests und Anpassungen durch, um eine genaue Farbanpassung zu erreichen.

Verwenden Sie die passende Rakelhärte für Ihre spezifische Tinten- und Substratkombination. Üben Sie während des Druckvorgangs einen gleichmäßigen Druck aus, um eine gleichmäßige Tintenabdeckung zu gewährleisten. Maintain a proper angle and speed while printing to avoid ink smearing or uneven application.

Entdecken Sie die Verwendung von Spezialtinten wie Metallic-Tinten, fluoreszierend, oder im Dunkeln leuchtende Tinten, um Ihren Drucken einzigartige visuelle Elemente zu verleihen. Erwägen Sie die Integration von Spezialeffekten wie dem Drucken mit hoher Dichte, Folienapplikationen, oder strukturierte Oberflächen, um auffällige und haptische Designs zu schaffen.

Lassen Sie Ihren Ausdrucken ausreichend Zeit zum Trocknen, bevor Sie sie anfassen oder aushärten, um ein Verschmieren oder eine Farbübertragung zu verhindern. Befolgen Sie die empfohlenen Aushärtungsanweisungen für Ihren spezifischen Tintentyp, um optimale Haltbarkeit und Waschbeständigkeit zu gewährleisten. Lagern und handhaben Sie fertige Drucke ordnungsgemäß, um Schäden oder ein Verblassen der Farbe im Laufe der Zeit zu vermeiden.

Bleiben Sie in Workshops über die neuesten Fortschritte und Techniken im Siebdruck auf dem Laufenden, Online-Tutorials, oder Branchenpublikationen. Holen Sie Feedback von erfahrenen Druckern oder Mentoren ein, um Verbesserungsmöglichkeiten zu identifizieren und Best Practices umzusetzen. Üben Sie regelmäßig, um Ihre Fähigkeiten zu verfeinern, und experimentieren Sie mit neuen Ideen, um die Grenzen Ihrer Siebdruckfähigkeiten zu erweitern.

Indem Sie diese Tipps umsetzen, Sie können die Qualität und Effizienz Ihres Siebdruckprozesses verbessern. Erinnern, Übung und kontinuierliche Verbesserung sind der Schlüssel zur Beherrschung der Kunst des Siebdrucks.

Fazit:

Während sich die Technologie weiterentwickelt, Die Welt der Siebdrucktechniken erweitert und diversifiziert sich immer weiter. Die Spitze 8 Die in diesem Artikel beschriebenen Arten von Siebdruckverfahren bieten einen Einblick in die spannenden Möglichkeiten und Anwendungen in 2023. Whether it’;Ob traditioneller Siebdruck für die Massenproduktion oder spezielle Techniken wie wasserbasierter Druck für Nachhaltigkeit, screen printing remains a versatile and powerful method for transferring designs onto various surfaces. With advancements in ink formulations, equipment, and design software, screen printing continues to push boundaries and inspire creativity in industries ranging from fashion to advertising.

Looking for top-notch customization of embroidery logo digitizing? Suchen Sie nicht weiter als EM-DIGITALISIERUNG! We specialize in delivering the highest quality embroidery logo Digitalisierung von Dienstleistungen. Plus, we have an exclusive offer for our first-time customers –; enjoy a whopping 50% Rabatt auf alle unsere Dienstleistungen. Get a free quote today and let us bring your vision to life! If you have any queries or comments, don’;t hesitate to reach out. Vielen Dank, dass Sie sich die Zeit genommen haben, diesen Artikel zu lesen!

Screen printing uses the technique of forcing ink through a stencil onto a substrate using a mesh screen. It is a versatile and widely used printing method for various materials.

The most popular printing method currently is DTG (Direkt zum Kleidungsstück) Drucken. It allows for high-quality, full-color prints directly onto garments, offering flexibility and intricate details.

When it comes to longevity, screen printing is known for its durability. The ink used in screen printing forms a strong bond with the fabric Entwurf, making it highly resistant to fading or cracking over time.

The latest printing technology in the industry is UV printing. It utilizes ultraviolet light to instantly cure the ink, allowing for printing on a wide range of surfaces and providing vibrant colors, sharp details, and quick drying times.

DTF (Direkt zum Film) Drucken ist eine relativ neue Technologie, die Kostenvorteile gegenüber herkömmlichen Siebdruckverfahren bietet. Es macht Bildschirme überflüssig und verkürzt die Einrichtungszeit, Dies macht es für bestimmte Anwendungen potenziell kostengünstiger.