Are you wondering whether to choose DTG vs screen printing for your next custom design project?

It’s a common question when you’re deciding how to print on fabric, and both methods have their own strengths.

DTG is great for detailed, colorful designs, while screen silk printing is ideal for larger orders and bold colors. In this article, we’ll guide you through the key differences between the two, so you can pick the best option for your specific needs.

Let’s explore which method will work best for your project!

Choosing Between DTG vs Screen Printing for Your Next Project

What Is DTG Printing?

Direct-to-Garment (DTG) printing is a modern method that involves printing designs directly onto the fabric using a specialized inkjet printer.

The process works similarly to how a regular home printer works, but instead of paper, it prints on fabric, primarily t-shirts.

DTG printing allows for high-resolution designs with vibrant colors and detailed graphics, making it ideal for those who want intricate and colorful designs on their apparel.

Key Advantages

- High Color Accuracy and Gradients: DTG printing excels at handling complex designs with intricate color gradients and details. It’s perfect for artwork that requires a wide range of colors and shading.

- Suitable for Small Orders: If you’re producing a small number of shirts or custom items, DTG is cost-effective because it doesn’t require a lot of preparation time or materials.

- Ease of Customization: DTG is perfect for one-off designs or items where each piece needs a slight variation, such as customized names or numbers on jerseys.

- Minimal Setup Time: Unlike screen silk printing, DTG printing doesn’t require a lengthy setup process, making it an excellent choice for rush orders.

Drawbacks

- Limitations with Bulk Orders: DTG is not cost-effective for large orders as the cost per item remains relatively high compared to screen silk printing, which becomes cheaper with more units.

- Shorter Lifespan of Prints on Certain Fabrics: DTG prints may not last as long as screen-printed designs, especially on synthetic fabrics. Washing and wearing can cause fading over time.

- Specific Material Preferences (100% Cotton): DTG works best on 100% cotton garments. It may not perform well on synthetic fabrics like polyester, limiting its material versatility.

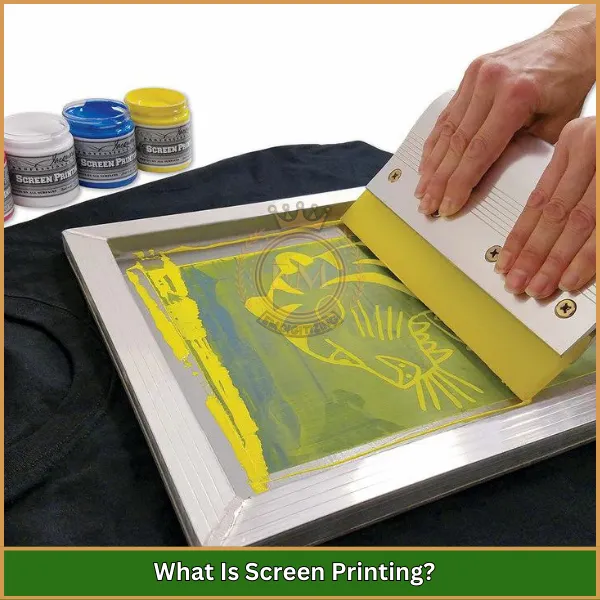

What Is Screen Printing?

It is also known as silkscreen printing, is a traditional method that has been around for decades. It involves using stencils (or “screens”) to press ink onto fabric in layers.

Each color in the design requires a separate screen, making it a more time-consuming process, but the results are long-lasting and vibrant.

Key Advantages

- Ideal for Bulk Printing: It becomes more economical with larger orders because the setup cost is spread across many units, reducing the cost per item.

- Rich, Vibrant Colors: This method produces highly saturated and opaque colors, which are excellent for bold designs that need to stand out on any fabric.

- Cost Efficiency for Large Batches: Once the screens are set up, the actual printing process is quick, making it very cost-effective for large print runs.

- Versatility Across Different Materials: It can be applied to a wide range of materials, including cotton, polyester, metal, glass, wood, and more.

Drawbacks

- Lengthy Setup Time: Each color in the design requires a separate screen, which takes time to prepare. This makes it less efficient for small or one-off orders.

- More Costly for Smaller Orders: The setup costs of this printing method can make it expensive for small print runs. The price per unit decreases with higher quantities but remains high for smaller jobs.

- Limited Color and Detail Capabilities: While it is great for bold and solid colors, it struggles with intricate details and complex gradients that DTG can easily handle.

Key Difference Between DTG vs Screen Printing

Let’s dive into the key differences between DTG vs screen printing, so you can make the best choice for your needs.

Printing Process and Setup Time

DTG uses a straightforward inkjet process that prints directly onto fabric with minimal setup, making it ideal for quick jobs and small orders. This process allows for detailed designs and a wide range of colors to be applied without much preparation.

On the other hand, screen silk printing requires the preparation of multiple screens for each color, which significantly increases setup time. For complex multi-color designs, screen silk printing can be time-consuming, but it becomes efficient when produced in bulk.

This difference in setup makes DTG printing vs screen printing a key consideration, especially if you’re on a tight schedule.

Cost Effectiveness for Different Volumes

One of the main factors to consider is cost-effectiveness. Screen printing becomes more economical as the volume increases since the cost per unit decreases once the screens are set up. This is why it’s the go-to method for larger batches of custom apparel.

In contrast, DTG is better suited for smaller orders because it doesn’t require an expensive setup, but the cost per unit remains higher for large quantities. If you’re deciding between DTG and screen printing for a bulk order, printing on screen will likely be the more budget-friendly choice.

Durability and Longevity of Prints

DTG vs screen printing durability is another crucial point. Printing on screen generally produces prints that are more durable and long-lasting.

The ink used in screen silk printing penetrates the fabric deeply, making it resistant to washing and fading over time.

DTG prints, while capable of producing vibrant and detailed images, may fade more quickly with repeated washing, especially if not cared for properly.

For garments that will be subjected to frequent wear and laundering, its counterpart is often the more durable option.

Versatility in Fabric and Material Usage

When it comes to fabric choices, screen printing offers more versatility. This method can be used on a wide range of materials, including cotton, polyester, leather, and even non-fabric surfaces like wood or metal.

DTG, however, works best on cotton and cotton-blend fabrics due to the way the ink adheres to the material. This limits DTG’s application to certain types of garments and projects, making printing on screen the superior choice for diverse fabric types.

Color and Design Capabilities

For intricate designs with lots of colors, DTG truly shines. It handles complex patterns, color gradients, and detailed images with ease, producing high-resolution prints that can replicate almost any design. In contrast, screen silk printing is better suited for bold, solid colors.

While it can produce multi-color designs, each additional color requires a separate screen, which can add to the time and cost of the project.

When comparing DTG and screen printing quality, DTG is the better option for designs that require a high level of detail and many colors, whereas its counterpart is ideal for simpler, bolder designs.

Best Situations to Use DTG vs Screen Printing

Best Situations | DTG | Screen Printing |

Order Size | Small to medium orders | Large volume orders |

Design Complexity | High-resolution, detailed, and multi-color | Simple, bold designs with fewer colors |

Turnaround Time | Quick production, minimal setup | Longer setup, faster for large quantities |

Material Suitability | Best for 100% cotton and cotton blends | Works on a wide range of materials (e.g., polyester, leather, etc.) |

Cost Efficiency | More cost-effective for small runs | More economical for bulk orders |

Durability | Moderate durability may fade with washing | Highly durable, long-lasting prints |

Customization | Ideal for personalized, one-off designs | Better suited for repeat designs and mass production |

Environmental Impact | Uses water-based inks, eco-friendly for small batches | Larger ink waste, not as environmentally friendly for small orders |

Bottom Line

Choosing between DTG and screen printing depends on what you need. DTG is great for small, colorful designs, while other printing method works best for big orders with simple designs. Knowing the difference helps you pick the right one for your project.

At EMdigitizing, we can help make your designs perfect for printing with our vector services. We work fast, offer affordable prices, and make sure your designs look great! Plus, if it’s your first time with us, you get 50% off.

Let us help you create something awesome!

FAQs

DTG printing typically does not last as long as screen printing. Screen printing usually offers more durable and vibrant results that can withstand repeated washing and wear over time.

Yes, DTG printing tends to be more expensive than screen printing, especially for larger orders. This is because DTG requires more expensive equipment and materials, making it less cost-effective for high-volume jobs.

Yes, DTG works best on 100% cotton and other natural fabrics. It produces high-quality, detailed prints on these materials, making it ideal for cotton apparel.

DTG prints can fade over time, especially with frequent washing. However, if proper care is taken, such as washing inside out and avoiding harsh detergents, the prints can last longer.