Are you wondering which ink is better for your printing project—water based ink vs plastisol? Both inks are popular choices in the printing world, but they serve different purposes depending on your needs. Water-based ink is loved for its eco-friendly nature and soft feel, while plastisol ink stands out for its durability and vibrant colors.

Choosing the right ink can be confusing, but it all depends on factors like fabric type, design requirements, and project goals. Whether you’re aiming for a breathable, natural finish or a bold, durable print, understanding the strengths of each ink can help you decide. Let’s dive into the details to find out which ink suits your needs best.

Water based Ink vs Plastisol Ink Which is Best Choice

What is Water-Based Ink?

It is a type of ink used in screen printing that relies on water as its primary solvent. This makes it eco-friendly and easy to clean compared to other inks. The ink penetrates the fabric fibers, creating a soft and breathable finish. Water-based ink is especially popular for printing on lighter fabrics and is known for its smooth, natural feel.

Pros

- Eco-Friendly: Less harmful to the environment due to water-based solvents.

- Soft Feel: Blends seamlessly into fabric, providing a breathable and natural texture.

- Great for Detailed Designs: Produces sharp and intricate details.

Cons

- Limited to Specific Fabrics: Performs better on lighter-colored fabrics.

- Drying Challenges: Requires more precise curing to prevent smudging.

Short Shelf Life: Dries out quickly in the screen if not managed properly.

What is Plastisol Ink?

It is a PVC-based ink commonly used in screen printing due to its durability and vibrant color output. Unlike water-based ink, it sits on top of the fabric rather than soaking into it, creating a slightly thicker texture. Plastisol ink is versatile, works on a variety of fabrics, and requires heat curing to set permanently. It’s popular for bold designs and multi-color prints.

Pros

- Vibrant Colors: Produces bright, opaque prints, even on dark fabrics.

- Versatile: Works well on almost all fabric types.

- Long Shelf Life: Does not dry out quickly, making it easy to store and reuse.

Cons

- Heavier Feel: Creates a thicker layer on fabric, less breathable than water-based ink.

- Environmental Impact: Contains PVC, which is less eco-friendly.

- Heat Curing Required: Needs precise temperature control for curing to avoid damage.

Key Differences Between Water Based Ink vs Plastisol Ink

1. Durability

Plastisol ink is known for its excellent durability, as it forms a thick layer on the fabric that resists cracking and fading, even after numerous washes. In contrast, water-based ink integrates into the fabric fibers, which can lead to fading over time, especially on darker materials.

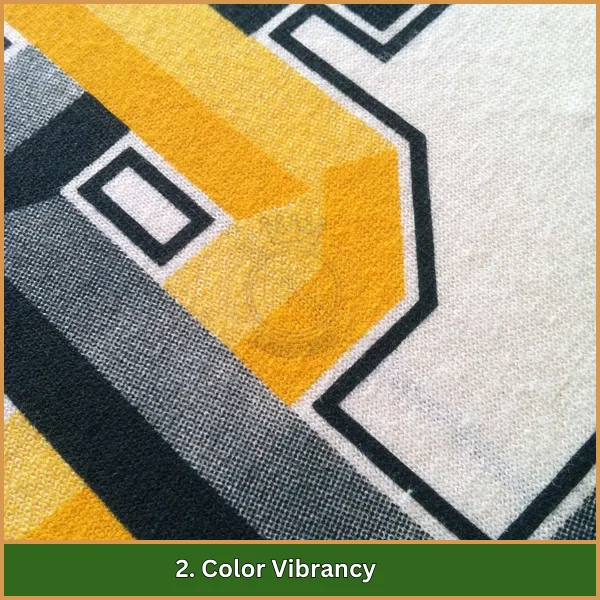

2. Color Vibrancy

Plastisol ink delivers vibrant, bold colors with high opacity, making it ideal for printing on dark fabrics or intricate designs. In the debate of plastisol vs water based ink, plastisol stands out for its ability to provide bright, consistent prints, while water-based ink offers softer and more natural tones, best suited for subtle designs.

3. Environmental Impact

Water-based ink is an eco-friendly option as it relies on water as its primary solvent and contains fewer harmful chemicals. Plastisol ink, being PVC-based, poses environmental concerns and requires proper disposal methods to avoid polluting the environment.

4. Texture and Finish

Water-based ink penetrates the fabric, leaving a smooth, natural feel that is soft to the touch. Plastisol ink, on the other hand, sits on the fabric’s surface, resulting in a heavier, slightly rubbery texture that is noticeable when worn.

5. Ease of Use

When comparing plastisol ink vs water based, plastisol ink is much easier to handle for beginners. It has a long shelf life and doesn’t dry out quickly, making it a user-friendly option. Water-based ink requires more skill and attention, as it dries faster during printing and can be challenging to manage.

6. Curing Process

Plastisol ink needs to be cured at a precise temperature using heat presses or conveyor dryers, ensuring it bonds to the fabric correctly. Water-based ink also requires curing, but the process often takes longer and may demand higher heat, making it slightly more complex.

7. Fabric Compatibility

When it comes to screen printing water based ink vs plastisol, water-based ink is best for natural fabrics like cotton, providing a soft, seamless finish. Plastisol ink, however, is more versatile and performs well on a variety of fabric types, including synthetics, making it the go-to option for mixed-material garments.

Which Ink (Water Based Ink vs Plastisol Ink) is Best for Your Printing Needs?

Deciding between water based vs plastisol ink requires understanding your project’s goals, fabric type, and the desired finish. Both inks have distinct advantages and disadvantages, catering to different needs in screen printing.

When to Choose Water-Based Ink

Water-based ink is ideal for projects that prioritize eco-friendliness and a soft, natural finish. Since it soaks into the fabric, it creates a breathable design that feels like part of the material. This makes it perfect for:

- Light-Colored Fabrics: Water-based ink works best on light, natural fabrics like cotton or linen. It’s not as vibrant on dark fabrics unless you use discharge inks.

- Eco-Conscious Projects: If reducing environmental impact is important, water-based ink is a great choice because it uses water as the solvent and contains fewer harmful chemicals.

- Soft Feel and Subtle Designs: The ink becomes part of the fabric, providing a lightweight and seamless texture ideal for vintage or understated designs.

However, it requires a precise curing process and may be less durable on heavy or dark fabrics.

When to Choose Plastisol Ink

Plastisol ink is the go-to option for bold, vibrant designs and versatility across fabric types. Since it sits on the surface of the material, it creates a thick, opaque layer that is highly durable. This makes it suitable for:

- Dark or Synthetic Fabrics: Plastisol ink provides excellent opacity, making it ideal for printing on dark colors or synthetic blends like polyester or nylon.

- Intricate and Vibrant Designs: The ink’s high vibrancy ensures bold and eye-catching prints, perfect for multi-color or detailed designs.

- Durability and Longevity: Plastisol ink can withstand numerous washes without fading, making it the better choice for garments requiring long-term use, such as workwear or uniforms.

- Beginner-Friendly Printing: It doesn’t dry out during use and is easy to store, making it ideal for those new to screen printing.

However, plastisol is less environmentally friendly and can create a heavier feel on the fabric, which might not suit all projects.

Conclusion

Deciding between screen printing water based ink vs plastisol comes down to your unique printing needs. Water-based ink offers a soft and eco-friendly option, perfect for breathable prints, while plastisol ink delivers bold colors and exceptional durability for high-impact designs.

Whatever your choice, the quality of your artwork makes all the difference. That’s where EMDigitizing steps in! We specialize in professional vector art services, offering unbeatable rates, lightning-fast turnaround times, and guaranteed quality. Plus, with our preview option, you can see exactly how your design will look before it’s finalized.

Are you a first-time customer? Great news! Enjoy a massive 50% discount on your first order. Let EMDigitizing help transform your designs into something truly outstanding!

FAQs

Water-based ink uses water as its primary solvent, allowing it to soak into the fabric for a soft, breathable finish. In contrast, plastisol ink is PVC-based and sits on top of the fabric, creating bold, opaque designs with a slightly thicker feel.

Water-based ink penetrates fabric fibers, giving a natural and lightweight print, while plastisol ink stays on the surface, delivering vibrant, high-opacity prints suitable for all fabric types.

Yes, but it may require special additives or pre-treatment to ensure proper adhesion and longevity when used on synthetic materials.

No, mixing these inks is not recommended because their chemical bases and curing processes are incompatible, leading to poor results and potential printing failures.