Conseils secrets rapides pour la sérigraphie en demi-teintes

Introduction:

Dans cet article, nous explorerons quelques conseils secrets rapides pour vous aider à maîtriser l'art de la sérigraphie en demi-teintes, vous permettant de créer des impressions en demi-teintes visuellement époustouflantes et d'aspect professionnel.

Conseils secrets rapides pour la sérigraphie en demi-teintes

Qu'est-ce que les demi-teintes?

L'impression en demi-teintes est une technique polyvalente qui permet de reproduire des détails complexes, nuances, et dégradés utilisant un nombre limité de couleurs d'encre. Il est largement utilisé dans diverses applications, y compris l'impression de vêtements, en demi teintes impressions artistiques, et matériel promotionnel.

Conseils pour la sérigraphie en demi-teintes

Maintenant que vous savez ce qu’est une sérigraphie en demi-teinte, passons à quelques astuces étonnantes pour l’impression en demi-teinte:

Comprendre l'impression en demi-teintes

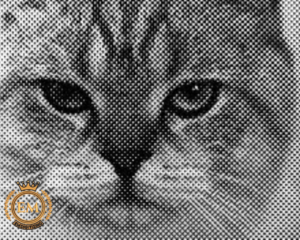

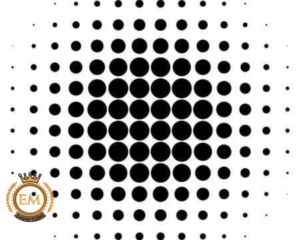

Pour exceller dans l'imprimante en demi-teintes, it’;Il est essentiel de comprendre le concept de base derrière le processus. L'impression d'images en demi-teintes consiste à décomposer les images en tons continus en une série de petits points dont la taille et la densité varient.. Ces points en demi-teinte, lorsqu'ils sont imprimés ensemble, créer l'illusion de différentes nuances et dégradés. La clé d’une impression en demi-teintes réussie réside dans la recherche du bon équilibre entre la taille des points d’impression, fréquence des points, et substrat d'impression.

Choisir le bon motif de demi-teintes

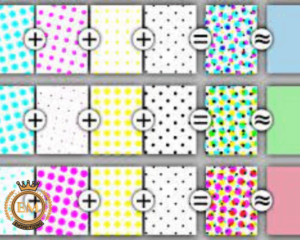

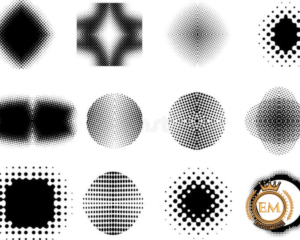

La sélection du motif de demi-teintes approprié est cruciale pour obtenir les résultats d'impression souhaités.. Différents modèles de demi-teintes, comme un point rond, point elliptique, et point carré, produire des effets visuels variés. Les points ronds sont couramment utilisés pour l'impression générale, tandis que les points elliptiques peuvent créer des transitions plus douces. Points carrés, d'autre part, donner une apparence plus traditionnelle et mécanique. L'expérimentation et les tests d'impression peuvent vous aider à déterminer le meilleur motif de demi-teintes pour votre projet spécifique. impression d'écran projet.

Préparation optimale des images

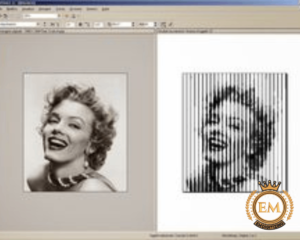

Une bonne préparation de l’image est essentielle pour une sérigraphie en demi-teinte réussie. Begin by adjusting the image’;le contraste et les niveaux pour améliorer les détails et assurer une bonne gamme tonale. Prochain, convertir l'image en niveaux de gris et ajuster sa résolution pour qu'elle corresponde à la taille d'impression prévue. Pensez à utiliser un logiciel de retouche d'image comme Adobe Photoshop pour contrôler avec précision la taille des points, fréquence, et angle. Pensez à tester l'impression et à affiner vos réglages pour obtenir l'effet demi-teinte souhaité.

Exposition appropriée à l'écran

Une exposition précise des tons d'écran est essentielle pour obtenir des impressions en demi-teintes nettes et nettes.. Assurez-vous que votre émulsion d'écran est correctement enduite, uniformément réparti, et exempt de débris. Use a quality exposure unit and follow the manufacturer’;s directives pour un temps d'exposition optimal. Une sous-exposition peut entraîner des points faibles et une mauvaise définition de l'image, tandis qu'une surexposition peut entraîner la fusion des points ou la perte de détails. Vérifiez et calibrez régulièrement votre configuration d'exposition pour maintenir une qualité d'impression constante..

Sélection du bon nombre de maillages

Le nombre de mailles de votre écran joue un rôle important dans la sérigraphie en demi-teintes en pointillés. Un nombre de mailles plus élevé produit des détails plus fins et des points plus petits, tandis que les nombres de mailles inférieurs conviennent mieux aux points plus gros et aux dépôts d'encre plus lourds.. Tenez compte de la texture du substrat et de la viscosité de l'encre lors de la sélection du nombre de mailles. It’;Il est important de trouver un équilibre pour garantir une couverture d'encre et une pénétration des points optimales sans obstruer l'écran ni sacrifier la qualité d'impression..

Application appropriée de l'encre

L'obtention d'impressions en demi-teintes cohérentes et éclatantes nécessite une application minutieuse de l'encre.. Utilisez une raclette avec la dureté appropriée, assurant une pression et un angle constants tout au long du trait d'impression. Maintenez un rapport encre/écran approprié pour éviter- ou sous-encrage, ce qui peut affecter la formation des points et la clarté de l'impression. Des tests d'impression et des ajustements peuvent être nécessaires pour obtenir la couverture d'encre et la saturation des points souhaitées..

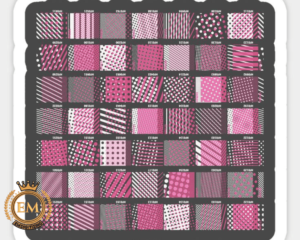

Expérimentation sur la forme des points:

Don’;Ne vous limitez pas au tour traditionnel, elliptique, ou des points carrés. Essayez d'expérimenter différentes formes de points, comme des diamants ou des triangles, pour créer des effets visuels et des textures uniques dans vos impressions.

Contrôle de la densité des demi-teintes:

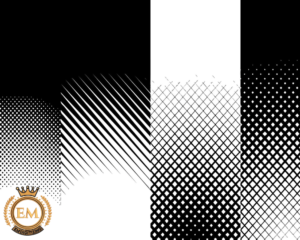

L'ajustement de la densité de vos points de demi-teintes peut avoir un impact significatif sur l'apparence générale de vos impressions.. Augmentez la densité des points pour les zones plus sombres pour ajouter de la profondeur et de la richesse, tout en diminuant la densité dans les zones plus claires pour obtenir des dégradés subtils.

Considérations relatives au substrat:

Gardez à l'esprit que différents substrats peuvent nécessiter des ajustements spécifiques dans votre processus d'impression en demi-teintes.. Facteurs tels que la texture de la surface, couleur, et le taux d'absorption peut influencer l'adhérence de l'encre et la clarté des points. Testez les impressions sur différents substrats pour déterminer les paramètres optimaux pour chacun.

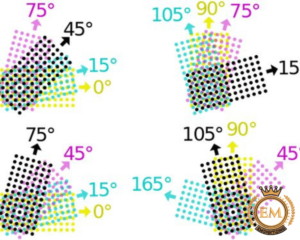

Variation de l'angle des demi-teintes:

La variation des angles de demi-teintes dans les impressions multicolores peut aider à réduire les motifs de moiré et à améliorer la qualité globale de l'impression.. Expérimentez avec différentes combinaisons d'angles pour trouver les résultats les plus attrayants et les plus équilibrés..

Nettoyage et entretien appropriés de l'écran:

Nettoyez et entretenez régulièrement vos écrans pour garantir une qualité d’impression optimale. Enlever l'excès d'encre, résidu d'émulsion, et les débris de la surface de l'écran pour éviter le colmatage et assurer une formation constante de points.

Contrôle de la température et de l'humidité:

Les conditions environnementales peuvent affecter les performances de vos encres et émulsions. Maintenez un environnement d'impression contrôlé avec des niveaux de température et d'humidité stables pour minimiser les problèmes de séchage de l'encre., distorsion des points, ou séchage par sérigraphie pendant le processus d'impression.

Paramètres de demi-teinte de réglage fin:

Faites attention aux détails et affinez continuellement vos paramètres de demi-teintes. Ajuster la taille du point, fréquence, et l'angle en fonction des exigences spécifiques de l'image et de l'impression pour obtenir l'impact visuel souhaité.

Inspection post-impression:

Après l'impression, inspectez soigneusement vos impressions en demi-teintes pour détecter toute imperfection ou incohérence. Recherchez des problèmes tels qu'une formation de points incomplète, saignement d'encre, ou une mauvaise inscription. Résolvez rapidement tout problème pour améliorer les futurs tirages.

Apprentissage continu et pratique:

La sérigraphie en demi-teintes est un art qui nécessite de la pratique et un apprentissage continu. Restez à jour avec les nouvelles techniques, outils, et les tendances de l'industrie. Expérimentez différentes combinaisons et approches pour élargir vos connaissances et affiner vos compétences.

Variation de la taille des demi-teintes:

Expérimentez en faisant varier la taille des points dans votre motif en demi-teintes. L'utilisation de différentes tailles de points peut ajouter un intérêt visuel, créer des textures, et améliorez la plage dynamique globale de vos impressions.

Contrôle du dégradé:

Obtenir des dégradés fluides dans les impressions en demi-teintes nécessite une attention particulière. Ajustez la taille et l'espacement des points dans les zones de transition pour garantir des dégradés homogènes et visuellement attrayants..

Considérations sur la base:

Lors de l'impression sur des supports sombres ou colorés, pensez à utiliser une couche de base pour améliorer l'éclat des impressions en demi-teintes. Alignez correctement la sous-couche avec les couches suivantes pour maintenir un enregistrement précis.

Mélange d'encre:

Explorez le monde du mélange d'encres personnalisé pour créer des couleurs et des tons uniques pour vos impressions en demi-teintes.. Expérimentez avec différentes combinaisons d'encres pour obtenir les effets visuels souhaités et élargissez vos possibilités créatives.

Tests d'impression et calibrage:

Effectuez régulièrement des tests d'impression pour évaluer la précision de votre configuration en demi-teintes.. Effectuer les ajustements nécessaires à la taille du point, densité, et angles en fonction des résultats. L'étalonnage de votre équipement et de votre flux de travail garantit une impression cohérente et fiable.

En intégrant ces conseils dans votre processus de sérigraphie d’images en demi-teintes, vous pouvez affiner davantage votre technique, élargissez vos possibilités créatives, et produisez systématiquement des impressions exceptionnelles qui se démarquent de la foule. Rappelles toi, la pratique et l'expérimentation sont essentielles pour maîtriser cette méthode d'impression polyvalente.

Conclusion:

La sérigraphie en demi-teinte ouvre un monde de possibilités pour créer des impressions visuellement captivantes. En comprenant les principes fondamentaux et en appliquant ces conseils secrets rapides, vous pouvez maîtriser l'art de l'impression en demi-teintes et produire des images de haute qualité, résultats professionnels. N'oubliez pas d'expérimenter, test, et affinez votre processus pour obtenir les effets souhaités. Avec de la pratique et une attention aux détails, vous pouvez faire passer votre sérigraphie en demi-teintes au niveau supérieur et créer des impressions époustouflantes qui captivent les spectateurs et laissent une impression durable.

If you’;Vous avez besoin de services de numérisation de broderie de logo personnalisé, NUMÉRISATION EM est la solution ultime. Nous sommes spécialisés dans la fourniture de logos brodés de premier ordre services de numérisation avec une qualité sans compromis. Profitez de notre offre exclusive de 50% réduction sur tous nos services pour les nouveaux clients. Demandez un devis gratuit aujourd'hui, and we’;je vous contacterai rapidement.

Nous espérons que cet article vous a fourni des informations précieuses. Si vous avez des questions ou des requêtes concernant le contenu, please don’;n'hésite pas à laisser un commentaire. Merci d'avoir pris le temps de lire!

Le processus de demi-teinte en sérigraphie consiste à convertir des images en tons continus en motifs de petits points.. Ces points varient en taille et en densité pour créer l'illusion de nuances et de dégradés dans l'image imprimée.. Cette technique permet la reproduction d'images photographiques en utilisant des couleurs d'encre limitées..

La meilleure demi-teinte pour la sérigraphie dépend de divers facteurs tels que le détail de l'image souhaité., le type de substrat, et le matériel d'impression utilisé. Les options de demi-teintes courantes incluent le point rond, point elliptique, et point carré. L'expérimentation et les tests peuvent aider à déterminer la demi-teinte la plus appropriée pour obtenir les résultats d'impression souhaités..

Pour créer une demi-teinte pour l'impression, un logiciel spécialisé comme Adobe Photoshop peut être utilisé. Le processus consiste à convertir l'image originale en tons continus en une série de petits points variant en taille et en espacement.. Paramètres du logiciel, comme la taille des points, fréquence, et angle, peut être ajusté pour obtenir l'effet de demi-teinte souhaité pour les exigences d'impression spécifiques.

L'utilisation de l'impression en demi-teintes offre deux avantages clés: Premièrement, il permet la reproduction d'un ton continu motif images, y compris les dégradés et les nuances, en utilisant un nombre limité de couleurs d'encre. Deuxièmement, l'impression en demi-teintes permet un contrôle précis de la taille et de la densité des points, résultant en une représentation précise des détails et des transitions plus douces dans l'image imprimée.

Les types courants de demi-teintes incluent les points ronds, point elliptique, et point carré. Chaque type a ses caractéristiques et peut produire différents effets visuels sur l'image imprimée. En outre, variations de la taille des points, espacement, et l'angle peut être utilisé pour créer des motifs de demi-teintes personnalisés qui répondent à des exigences d'impression spécifiques et à des préférences artistiques.