Cuando se trata de la impresión de pantalla, El tipo de malla que usa puede afectar en gran medida el resultado de su diseño.. La malla de impresión de pantalla determina la cantidad de tinta y qué tan finos aparecerán sus detalles de diseño.

El uso de la malla correcta ayuda a garantizar que sus impresiones salgan claras y vibrantes.En esta guía, Cubriremos los conceptos básicos de los diferentes tipos de malla., Cómo elegir el correcto, y algunos consejos de cuidado simples para mantener sus pantallas en buenas condiciones.

Al dominar estos detalles, you’;podrá lograr mejores resultados de impresión.

Todo lo que necesita saber sobre la malla de serigrafía

¿Qué es la malla de serigrafía??

Es una tela finamente tejida que sirve como una plantilla en el impresión de pantalla proceso, utilizado para transferir tinta a diferentes superficies como la tela, papel, vaso, y metal. Permite que la tinta pase a través de áreas abiertas mientras evita que llegue a partes de la superficie no destinadas a imprimir. La malla se estira firmemente sobre un marco, y el recuento de malla y el tipo de material influyen en la cantidad de tinta aplicada y la precisión de los detalles impresos.

¿Cuáles son los tipos de malla de pantalla para imprimir??

Viene en varios tipos, cada una adecuada para diferentes necesidades de impresión basadas en el recuento de material y malla. Estas diferencias afectan la deposición de la tinta, detalle de la imagen, y calidad de impresión general.

Los tipos son:

- Malla de poliéster

- Malla de acero inoxidable

- Malla de nylon

- Malla de seda

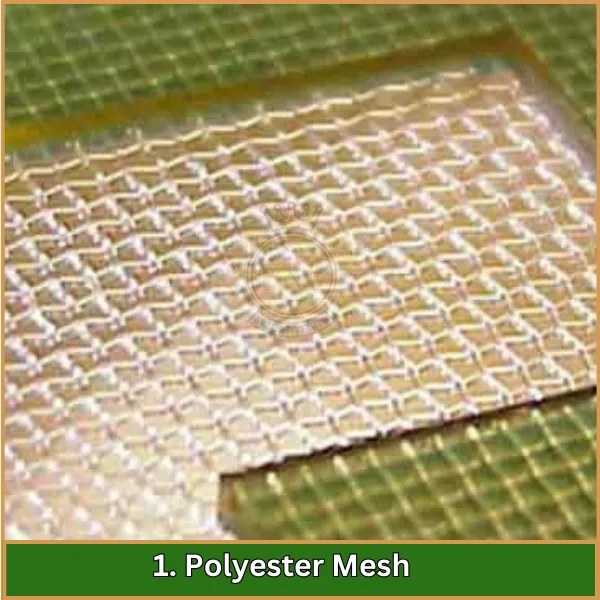

1. Malla de poliéster

La malla de poliéster es una tela sintética comúnmente utilizada en malla de pantalla para imprimir Debido a su resistencia y resistencia química.

Características clave:

- Alta resistencia a la tracción y durabilidad

- Resistente a la degradación química

Usos:

- Ideal para imprimir en textiles, cerámica, y productos planos o cilíndricos.

Beneficios:

- La malla de poliéster es asequible y versátil, Adecuado para una variedad de trabajos de impresión.

Limitaciones:

- Puede estirarse más bajo tensión alta, que puede afectar el registro de impresión.

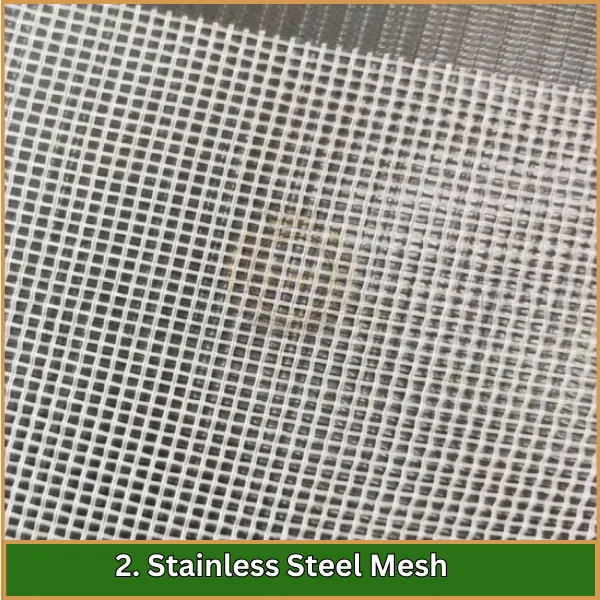

2. Malla de acero inoxidable

La malla de acero inoxidable es una muy duradera Impresión de pantalla de malla Hecho de cables de metal, utilizado para su resistencia al calor y los productos químicos.

Características clave:

- Extremadamente duradero y fuerte

- Alta resistencia al calor y a los químicos duros

Usos:

- Utilizado en electrónica, impresión de vidrio, y aplicaciones que requieren un control preciso de depósito de tinta.

Beneficios:

- Excelente para impresiones de alta precisión y ofrece una durabilidad superior.

Limitaciones:

- Más caro en comparación con otros tipos de malla de impresión de pantalla.

3. Malla de nylon

Nylon Mesh es una tela flexible y estirable, favorecido por su adaptabilidad a las superficies irregulares.

Características clave:

- Alta flexibilidad y capacidad de estiramiento

- Buena resistencia a la abrasión

Usos:

- Adecuado para superficies irregulares y sustratos abrasivos como vidrio y cerámica.

Beneficios:

- Se adapta bien a superficies desiguales, proporcionando más versatilidad.

Limitaciones:

- Menos resistente al solvente que el poliéster, que puede limitar su uso con ciertas tintas.

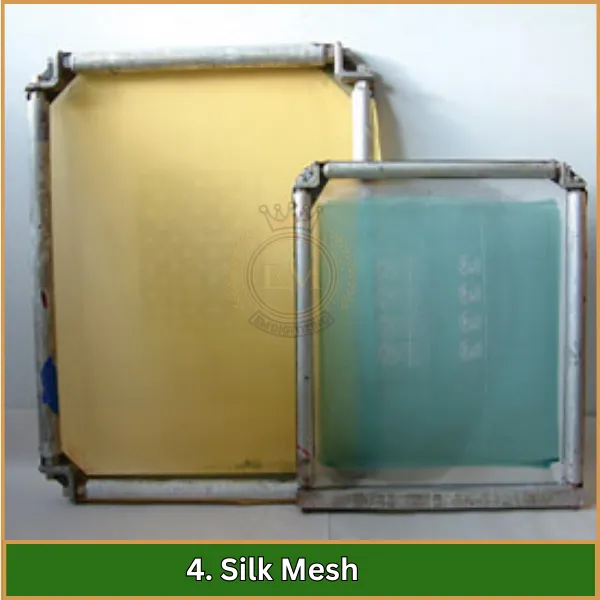

4. Malla de seda

La malla de seda es un material tradicional utilizado en Imprimir malla de pantalla por su capacidad para detallar las obras de arte fino, utilizado principalmente en grabado de alta calidad.

Características clave:

- Material tradicional para la impresión de pantalla

- Capacidad de detalle fino

Usos:

- Mayormente utilizado en artístico, Impresión de alta calidad y aplicaciones industriales limitadas.

Beneficios:

- Excelente para crear obras de arte detalladas con un acabado de alta calidad.

Limitaciones:

- No tan duradero como los materiales sintéticos y sensibles a las condiciones ambientales, requiriendo un manejo más cuidadoso.

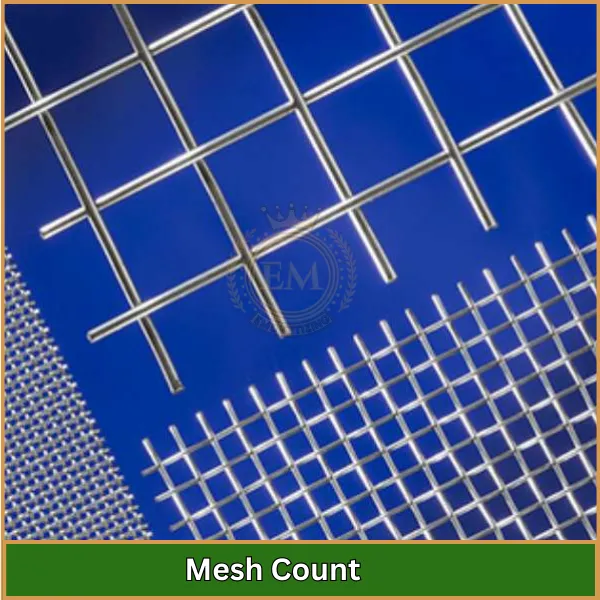

¿Qué es el recuento de malla de impresión de pantalla??

El recuento de malla se refiere al número de hilos por pulgada en una malla de impresión. Esta medición es crucial ya que afecta directamente la resolución, deposición de tinta, y el nivel de detalle que se puede lograr en el proceso de impresión.

Cuentas de malla más altas medias hilos más finos y aberturas más pequeñas, que son excelentes para diseños detallados y capas de tinta delgada. En cambio, Los recuentos de malla más bajos tienen aberturas más grandes, Adecuado para tintas más gruesas y gráficos más audaces.

Tipos comunes de recuento de malla y sus aplicaciones

Conteo de malla | Descripción | Aplicaciones comunes |

32T | Bajo recuento de malla, Permite más deposición de tinta, Ideal para diseños audaces. | Tintas especiales como brillo o copas. |

43T | Bajo recuento de malla, bueno para depósitos de tinta pesados. | Impresión textil con excelente cobertura. |

55T | Bajo recuento de malla, equilibrar la cobertura y la definición. | Impresión textil y aplicaciones generales. |

64T | Recuento de malla media, Adecuado para varios materiales. | Impresión en textiles, papel, y cartón. |

77T | Recuento de malla media, Bueno para detalles más finos. | Prendas livianas e impresión en papel. |

90T | Comúnmente utilizado para diseños de detalles más altos. | Impresiones de capa superior en tela y papel. |

110T | Recuento de malla versátil, Adecuado para diseños audaces. | Impresión de camisetas e impresión de pantalla de uso general. |

156T | Recuento de malla media, Balances detalles y cobertura de tinta. | Impresión textil con detalles moderados y colores audaces. |

230T | Alto recuento de malla, Ideal para detalles finos y tintas delgadas. | Impresiones de alta resolución en telas más ligeras y papel. |

305T | Recuento de malla muy alto, permite diseños intrincados. | Ilustraciones de arte detalladas y medias en superficies suaves. |

Impacto del recuento de malla en la impresión

El recuento de malla en la impresión de pantalla juega un papel fundamental en la determinación de la calidad y las características de la impresión final. Esencialmente, Afecta tres aspectos principales de la impresión: resolución, deposición de tinta, y la textura de la impresión.

- Resolución: Un recuento de malla más alto, con más hilos por pulgada, Resulta en una malla más fina. Esto permite imprimir detalles más finos porque puede contener puntos más pequeños de tinta.. Es ideal para diseños intrincados o texto pequeño que requiere alta precisión.

- Deposición de tinta: La cantidad de tinta que pasa a través de la malla al sustrato varía con el recuento de malla. Los recuentos de malla más bajos tienen aberturas más grandes, que permiten pasar un mayor volumen de tinta, creando una impresión más densa y más opaca. Esto es particularmente beneficioso para diseños en negrita o cuando se usa tintas especializadas como metálico o brillo.

- Textura de la impresión: La textura de la impresión final también puede estar influenciada por el recuento de malla. Malla más gruesa (recuento de malla más bajo) generalmente da como resultado una capa de tinta más gruesa, que puede agregar una textura notable a la impresión. En cambio, Los recuentos de malla más altos colocan una capa de tinta más delgada, que puede ser más suave al tacto.

Estos factores contribuyen colectivamente a la versatilidad de las técnicas de pantalla de impresión de malla, Permitir la personalización de acuerdo con las necesidades específicas del trabajo de impresión, Desde imágenes artísticas detalladas hasta diseños comerciales robustos.

Consideraciones para seleccionar la malla de impresión de pantalla

Al elegir la malla correcta para la impresión de pantalla, Se deben evaluar varios factores para garantizar una calidad de impresión y eficiencia de impresión óptimas.

Tipo de material

El material de la malla puede influir en su durabilidad, compatibilidad con tinta, y calidad de impresión. Los materiales comunes incluyen poliéster, nylon, y acero inoxidable, cada uno ofrece diferentes beneficios dependiendo de la aplicación de impresión.

Conteo de malla

Seleccionar el recuento de malla apropiado es crucial ya que afecta la resolución y la cantidad de tinta depositada. Se utilizan recuentos de malla más altos para impresiones detalladas en superficies suaves, Mientras que los recuentos más bajos son mejores para impresiones en negrita en superficies rugosas.

Diámetro de hilo

El diámetro de las hilos en la malla puede afectar el depósito general de tinta y el detalle de la impresión. Los hilos más finos proporcionan impresiones detalladas con menos depósito de tinta, Adecuado para diseños de alta detonancia.

Tensión de malla

La tensión de malla adecuada es esencial para evitar problemas como impresiones borrosas o distribución desigual de tinta. La tensión más alta generalmente da como resultado una mejor calidad de impresión.

Color de malla

El color de la malla puede afectar los tiempos de exposición durante el proceso de fabricación de pantalla y, en última instancia, afectar la impresión. White Mesh ofrece tiempos de exposición más bajos, Adecuado para detalles más finos, mientras que la malla amarilla o naranja ayuda con imágenes más nítidas y es mejor para un trabajo muy fino detallado.

Consejos de mantenimiento y limpieza para la malla de impresión de pantalla

Para preservar la calidad y extender la vida útil de su malla de impresión, El cuidado y la limpieza adecuados son esenciales. Aquí hay algunas pautas directas a seguir:

- Limpieza Regular: Limpie la malla de inmediato después de cada uso para evitar que la tinta se se seque y obstruya las aberturas de la malla.

- Manejo suave: Al limpiar, Use pinceles suaves o esponjas para evitar dañar los hilos de malla.

- Químicos específicos: Elija soluciones de limpieza diseñadas específicamente para mallas, asegurando que eliminen efectivamente la tinta sin dañar la tela.

- Enjuague completo: Siempre enjuague la malla siempre con agua después de la limpieza para eliminar cualquier limpiador o tinta restante.

- Secado adecuado: Asegúrese de que la malla esté completamente seca antes de almacenarla en una limpieza, área seca para evitar problemas con moho o moho.

Seguir estos consejos ayudará a mantener el rendimiento de su malla de impresión y lograr impresiones consistentemente de alta calidad.

Conclusión

Elegir la malla de impresión de pantalla correcta puede marcar una gran diferencia en la calidad de sus impresiones. Al comprender cómo la malla impacta el flujo de tinta y los detalles de diseño, puedes lograr más claro, Más resultados profesionales. El cuidado y el mantenimiento adecuados también ayudarán a extender la vida útil de sus pantallas y mantener sus impresiones con fuerza.

Buscando mejorar sus proyectos de impresión de pantalla? EMDigitalización ofrece experto servicios de arte vectorial Diseñado para satisfacer sus necesidades. Con tiempos de respuesta rápidos, precios asequibles, y trabajo de alta calidad, nos aseguramos de que sus diseños estén listos para imprimir con precisión. Más, disfruta de un 50% descuento en tu primer orden! Permítanos ayudarlo a llevar su impresión al siguiente nivel.

preguntas frecuentes

Sí, puede impresión de pantalla en pantalones cortos de malla, Pero es importante ajustar correctamente la distancia fuera del contacto. El uso de un material de respaldo también puede ayudar a evitar que la tinta sangre a través de la malla.

Elegir el recuento de malla correcto depende de la complejidad del diseño y el tipo de tinta. Los recuentos de malla más altos son ideales para detalles más finos y tintas más delgadas, Mientras que los recuentos más bajos funcionan mejor para diseños audaces y tintas más gruesas.

Para limpiar la malla de serigrafía, Aplique un lavado de pantalla o removedor de emulsión, Frota suavemente con un cepillo suave para aflojar cualquier tinta o residuo, y luego enjuague bien con agua.

Para exponer malla de serigrafía, Cubra la pantalla con una emulsión sensible a la luz y deja que se seque. Después, Coloque su diseño en la pantalla y exponga a una fuente de luz UV para la cantidad de tiempo recomendada, Dependiendo de tu tipo de emulsión.