Starting a custom patches business sounds exciting, doesn’t it? But before you jump in, there’s one big decision to make—choosing the best embroidery machine for custom patches. The right machine can turn your creative ideas into high-quality patches that stand out, but with so many options available, where do you even begin?

Don’t worry! Whether you’re just starting or looking to level up, understanding the must-have features in an embroidery machine is the first step. From exploring essential functionalities to showcasing top recommendations, we’ve got everything you need to make an informed decision.

Let’s dive in and discover the perfect machine to bring your custom patch business to life!

How to Choose the Right Embroidery Machine for Custom Patches Business?

Key Features to Look for in an Embroidery Machine for Custom Patches

Choosing the right machine for custom patches is essential for delivering high-quality designs and managing your business efficiently. Here are the key features to focus on when selecting a machine.

1. Embroidery Area and Hoop Sizes

The embroidery area determines the maximum size of patches you can create. Look for a machine that supports a variety of hoop sizes, as this flexibility will allow you to produce both small and large patches. A larger embroidery area also enables you to embroider multiple patches simultaneously, saving production time.

2. Multi-Needle vs. Single-Needle Machines

The choice between a multi-needle and a single-needle machine depends on your business size and requirements:

- Multi-Needle Machines: Ideal for businesses producing complex, multi-color designs quickly. These machines allow multiple threads to be set up at once, speeding up production.

- Single-Needle Machines: Best for beginners or small-scale operations, offering affordability but slower production speed.

3. Stitching Speed and Precision

For a successful custom patches business, speed and precision are key. Machines with high stitching speeds (measured in stitches per minute) can handle bulk orders more efficiently. However, precision is equally important to ensure the accuracy of intricate designs. Choose a machine with adjustable speed settings to balance speed and detail.

4. Built-in Designs and Customization Options

While built-in designs and fonts are useful, the ability to upload and customize designs is crucial for creating unique patches. Look for machines compatible with professional embroidery software that allows you to digitize and upload custom designs effortlessly.

5. Compatibility with Embroidery Software

A good embroidery machine for custom patches should support widely-used file formats like DST, PES, or EXP. This ensures seamless integration with embroidery software, allowing you to create and edit complex designs with ease. Compatibility with digitizing software is essential for scaling your custom patch business.

Types of Embroidery Machine for Custom Patches

Selecting the right type of machine for custom patch production is essential to ensure quality and efficiency. Each type of embroidery machine caters to different business needs, from beginners to large-scale operations.

1. Home Embroidery Machines

Home embroidery machines are compact, budget-friendly, and designed for hobbyists or small-scale businesses. These machines are typically single-needle and include basic features suitable for simple patch designs. While they lack the speed and capacity for large orders, they are ideal for beginners looking to experiment with creating custom patches.

Key Features:

- Affordable and easy to use.

- Limited embroidery area, suitable for small patches.

- Slower stitching speed, making them less suitable for high-volume production.

2. Commercial Embroidery Machines

A custom patch embroidery machine in the commercial category is built for businesses requiring high productivity and efficiency. These machines are often multi-needle, allowing you to use multiple thread colors simultaneously, making them ideal for complex and colorful patch designs.

Key Features:

- Multi-needle setup for faster production.

- Larger embroidery area for creating multiple patches at once.

- Higher stitching speed, perfect for large-scale production.

3. Computerized Embroidery Machines

Computerized embroidery machines are equipped with advanced technology, enabling seamless integration with embroidery software. These machines offer precision and automation, making them perfect for businesses that focus on custom and intricate patch designs.

Key Features:

- Support for a variety of embroidery file formats like DST or PES.

- Ability to upload custom designs via USB or Wi-Fi.

- Automated threading and tension control for ease of use.

4. Industrial Embroidery Machines

Industrial embroidery machines are designed for large-scale production. These machines are often multi-head, allowing simultaneous embroidery of multiple patches, which significantly boosts productivity. They are ideal for businesses with high-demand clients or those producing thousands of patches.

Key Features:

- Multi-head configuration for mass production.

- Durable and designed for continuous use.

- Superior speed and precision for bulk orders.

Top Embroidery Machine Recommendations for Custom Patches

Selecting the right embroidery machine is crucial for producing high-quality custom patches efficiently. Below are top recommendations categorized to suit various business needs and expertise levels.

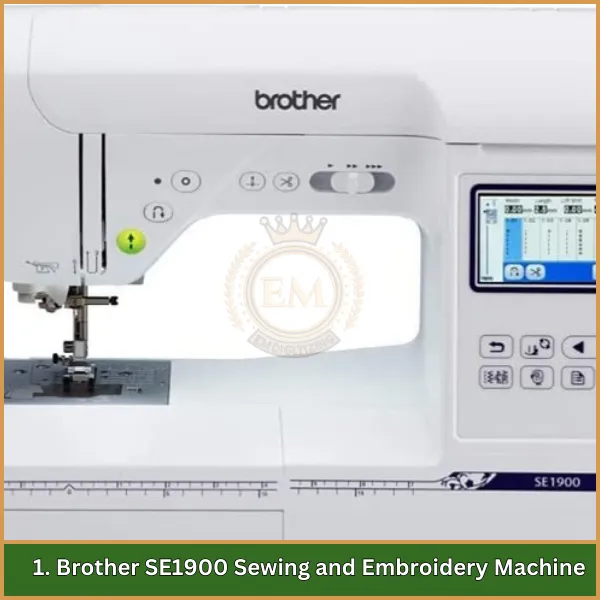

1. Brother SE1900 Sewing and Embroidery Machine

The Brother SE1900 is a versatile machine ideal for both beginners and experienced users. It features a 5″ x 7″ embroidery area, 138 built-in designs, and 11 fonts, allowing for diverse and intricate patch creations. The large color touchscreen facilitates easy design editing and previewing.

Key Features:

- 5″ x 7″ embroidery field

- 138 built-in designs and 11 fonts

- Large color touchscreen for intuitive navigation

- Combination of sewing and embroidery functions

2. Janome Memory Craft 500E Embroidery Machine

The Janome Memory Craft 500E is designed for dedicated embroidery tasks, offering a large embroidery area of 7.9″ x 11″. It includes 160 built-in designs and six fonts, with advanced editing capabilities accessible via its LCD touchscreen. This machine is suitable for users aiming to produce larger patches with intricate details.

Key Features:

- 7.9″ x 11″ embroidery area

- 160 built-in designs and six fonts

- Advanced editing features on an LCD touchscreen

- USB port for importing custom designs

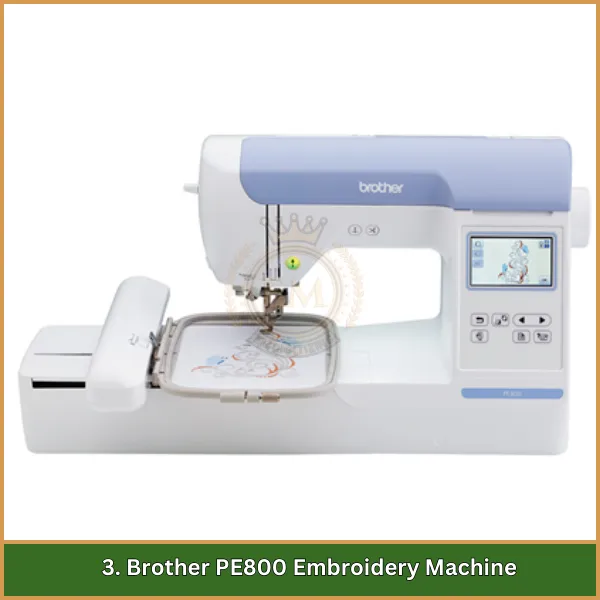

3. Brother PE800 Embroidery Machine

The Brother PE800 is a user-friendly machine perfect for those new to embroidery. It offers a 5″ x 7″ embroidery field, 138 built-in designs, and 11 fonts. The color touchscreen allows for easy design editing and previewing, making it a great choice for creating custom patches.

Key Features:

- 5″ x 7″ embroidery area

- 138 built-in designs and 11 fonts

- Color touchscreen for intuitive navigation

- USB port for importing custom designs

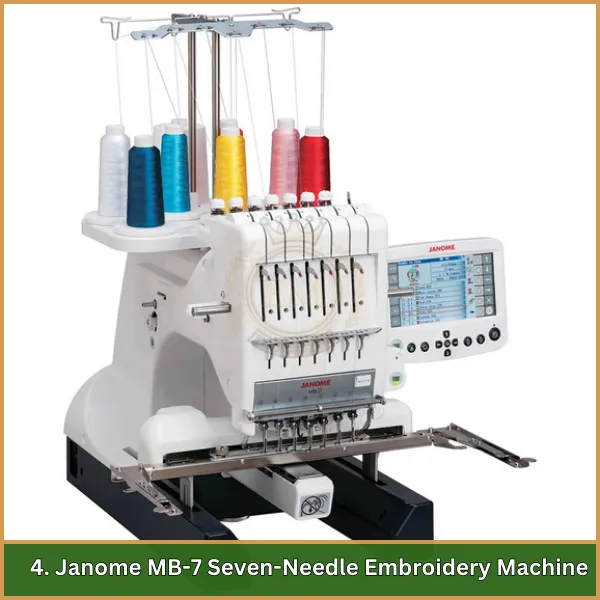

4. Janome MB-7 Seven-Needle Embroidery Machine

For businesses requiring higher production capacity, the Janome MB-7 offers a seven-needle configuration, allowing for multiple thread colors without manual changes. It features a 9.4″ x 7.9″ embroidery area and is compatible with various embroidery formats, making it suitable for complex and colorful patch designs.

Key Features:

- Seven-needle setup for efficient multi-color embroidery

- 9.4″ x 7.9″ embroidery area

- Compatible with multiple embroidery formats

- Remote computer screen (RCS) for easy design editing

5. Brother PR1055X Ten-Needle Embroidery Machine

The Brother PR1055X is a professional-grade machine designed for high-volume production. With ten needles, it allows for extensive color combinations without manual thread changes. It features a large embroidery area of 14″ x 8″ and advanced capabilities such as wireless connectivity and a built-in camera for precise positioning.

Key Features:

- Ten-needle configuration for high efficiency

- 14″ x 8″ embroidery area

- Wireless connectivity for design transfer

- Built-in camera for accurate design placement

When choosing an embroidery machine for custom patches, consider factors such as production volume, design complexity, and budget to select the most suitable option for your business needs.

Conclusion

Now that you’ve chosen the perfect embroidery machine for custom patches, it’s time to bring your designs to life! A great design starts with precise digitizing, and that’s where EMdigitizing comes in.

At EMdigitizing, we specialize in delivering top-notch patch digitizing services to ensure your custom patches look flawless. Plus, we’re making it even easier to get started by offering a 50% discount on your first order!

Ready to take your patches to the next level? Contact us today and get a free quote in just 5 minutes. Let us help you turn your creative vision into stunning custom patches!

FAQs

Absolutely! An embroidery machine is perfect for making custom patches. It allows you to stitch intricate designs onto fabric, which can then be cut out and finished into professional-quality patches.

Both single-needle and multi-needle embroidery machines can be used for making custom patches. Machines with larger embroidery fields, durable frames, and advanced features are particularly ideal for efficient patch production.

Key features to consider include automatic thread cutting, a large embroidery area, and a color touchscreen for easy design navigation. These features enhance precision and make the patch-making process faster and easier.

To create custom patch designs, you’ll need embroidery digitizing software that converts artwork into stitch files compatible with your machine. Popular choices include Wilcom, Brother PE-Design, or Adobe Illustrator with embroidery plugins.