Eco-friendly screen printing is a creative way to make unique designs while being kind to the planet. By using sustainable materials and reducing waste, you can enjoy the art of printing without harming the environment.

This guide will help you understand everything about eco-friendly printing, from what tools and materials you need to tips for making the process smooth and efficient. Whether you’re just starting or looking to make your printing process more sustainable, you’ll find all the steps here to create beautiful prints the green way.

Let’s jump in and start printing responsibly!

Complete Guide on Eco-Friendly Screen Printing

Key Supplies for Eco-Friendly Screen Printing

Choosing the right supplies for eco friendly screen printing is the foundation of creating environmentally responsible designs. Here’s a list of essential materials that align with sustainable practices:

- Plant-based inks

- Compostable squeegees

- Reusable mesh screens

- Sustainable fabric options

- Durable and washable stencils

- Chemical-free cleaning agents

1. Plant-Based Inks

Say goodbye to harmful chemical inks and hello to plant-based alternatives! These inks are crafted from natural oils and pigments, ensuring vibrant prints without compromising the planet.

Pro Tip: Opt for Permaset Aqua for a range of eco-friendly colors that stand out.

2. Compostable Squeegees

Traditional plastic squeegees are out—compostable squeegees are in! Made from materials like bamboo, these squeegees are sturdy during use and gentle on the environment when it’s time to dispose of them.

Why Bamboo? It’s renewable, durable, and compostable.

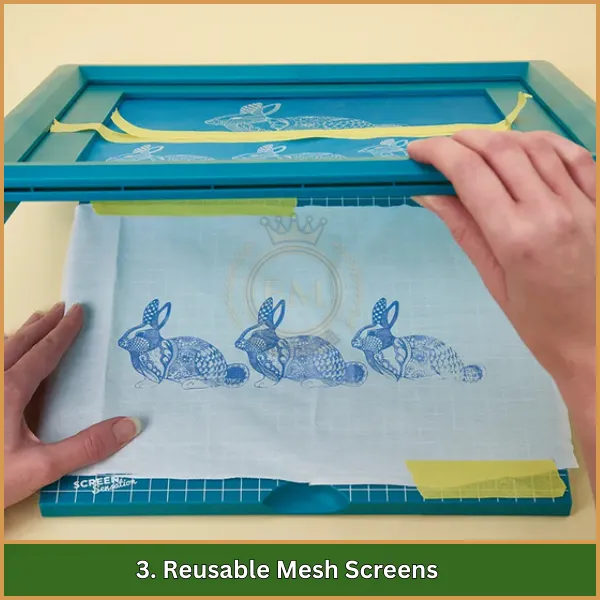

3. Reusable Mesh Screens

A greener approach to screen printing involves reusable mesh screens. These screens are easy to clean and recoat, reducing waste and saving money in the long run.

Top Choice: Aluminum screens paired with polyester mesh offer the perfect balance of durability and reusability.

4. Sustainable Fabric Options

The fabric you choose is just as important as the ink. Sustainable options like organic cotton or recycled fibers support environmentally responsible practices and provide a better feel for the final product.

Pro Recommendation: Look for fabrics labeled GOTS-certified for guaranteed eco-friendliness.

5. Durable and Washable Stencils

Washable stencils help you cut down on waste while maintaining consistency in your designs. They’re easy to clean and reuse, making them a must-have for sustainable printing.

Best Material: Metal stencils last longer and can withstand frequent use.

6. Chemical-Free Cleaning Agents

Cleaning up after printing doesn’t have to harm the environment. Chemical-free cleaners made from natural ingredients ensure a safe, effective cleanup without polluting water supplies.

Eco-Friendly Pick: Citrus-based cleaners like Franmar deliver excellent results with zero toxicity.

Step-by-Step Process for Eco-Friendly Screen Printing

It is a creative and sustainable way to produce stunning designs while minimizing environmental harm. By following these detailed steps, you can achieve professional results without compromising your commitment to sustainability.

1. Create Your Artwork

The foundation of any screen printing project is the design. Use graphic design software like Adobe Illustrator, CorelDRAW, or Canva to create your artwork. Focus on clean, bold designs with minimal fine details to make the printing process easier and reduce ink usage. Once your design is complete, print it onto a transparent film, which will later be used to create the stencil.

2. Prepare Your Screen

Select a reusable mesh screen made of polyester or stainless steel and attach it to a recyclable aluminum frame. Apply an eco-friendly emulsion evenly across the screen using a scoop coater. This emulsion will help create the stencil by blocking out areas of the screen. Place the coated screen in a dark, dust-free environment to dry completely. Drying can take a few hours depending on the emulsion type and temperature.

3. Transfer the Design

Position the transparent film with your design on the dried emulsion-coated screen. Secure it firmly, ensuring it doesn’t shift during exposure. Use a UV light source to expose the screen for the recommended time based on your emulsion. The light hardens the emulsion in areas not covered by the design, while the covered areas remain soft. Once exposed, gently rinse the screen with water to remove the soft emulsion, revealing your stencil.

4. Align for Printing

Set up your printing area by placing the prepared screen over the fabric or material you plan to print on. Ensure the screen is tightly secured and aligned with the material to avoid smudging or misplacement. Accurate positioning is crucial, especially when printing multiple items or using multi-layered designs.

5. Print with Sustainable Ink

Use sustainable screen printing ink, such as water-based or plant-based inks, to stay eco-friendly. These inks are free from harmful chemicals like PVC and phthalates, making them safer for the environment and users. Apply the ink at the top of the screen, then use a compostable squeegee to pull the ink evenly across the stencil. Ensure consistent pressure to achieve an even transfer of the design onto the material.

6. Dry and Cure

After printing, let your designs air dry naturally, or use a low-energy heat press or curing unit to speed up the process. Proper curing ensures the ink bonds with the material, making the design more durable and resistant to wear and washing. If using heat, keep the temperature low to reduce energy consumption and protect the fabric.

7. Clean Responsibly

Cleaning up after printing is an essential part of the process. Use biodegradable, non-toxic cleaning solutions to wash the screen, squeegee, and other tools. Avoid letting ink dry on the screen, as this can make cleanup more difficult and shorten the screen’s lifespan. Proper cleaning not only ensures your tools last longer but also keeps your printing process sustainable.

8. Store for Future Use

Once everything is clean and dry, store your screens, squeegees, and other tools in a cool, dry place. Reusing your materials reduces waste and saves money, making your screen printing process more efficient and environmentally friendly over time.

Tips for Minimizing Waste in Screen Printing

When it comes to eco-friendly screen printing, minimizing waste is a simple yet impactful way to reduce your environmental footprint. Here’s how you can do it:

- Stick to reusable tools like mesh screens, frames, and stencils that can be cleaned and used again.

- Save any leftover ink after each session, as it can be reused for future projects or mixed to create new colors.

- Only mix and use the exact amount of ink needed to avoid wasting excess material.

- Switch to biodegradable cleaning products to wash your tools without harming the planet.

- Print on sustainable fabrics, such as organic cotton or recycled materials, to promote greener practices.

- Turn mistakes or scrap fabric into test prints or samples instead of tossing them out.

- Arrange designs carefully on your material to make the most of every inch and reduce waste.

- Share knowledge about waste reduction with others to encourage sustainable printing habits.

By incorporating these practices, you can make your screen printing process cleaner, greener, and more efficient.

Bottom Line

Eco-friendly screen printing lets you create stunning designs while staying kind to the planet. With sustainable materials and thoughtful methods, you can make a big impact without compromising on quality.

Need professional vector art to take your prints to the next level? EMDigitizing has you covered! We provide high-quality vector art services at unbeatable prices, with lightning-fast turnaround and guaranteed results. You can even preview your design before it’s finalized. Plus, as a first-time customer, you’ll enjoy an exclusive 50% discount on your order!

Don’t wait—reach out to us today and let’s bring your creative vision to life!

FAQs

It is a sustainable printing method that uses non-toxic inks, reusable tools, and recycled materials to minimize harm to the environment.

Unlike traditional screen printing, eco-friendly methods avoid toxic chemicals, reduce waste, and use less energy, making the process safer for both people and the planet.

It helps protect the environment, ensures safer working conditions, and appeals to eco-conscious customers, boosting your brand’s image.

Yes, eco-friendly printing works on many materials like organic cotton, hemp, and recycled fabrics, providing flexibility for different projects.