What is DTF Printing? DTF T-Shirt Printing At Home

Introduction:

In this article we will delve into the intricacies of DTF printing shirt and explains how it has revolutionized t-shirt printing, empowering individuals to create custom designs in the comfort of their own homes.

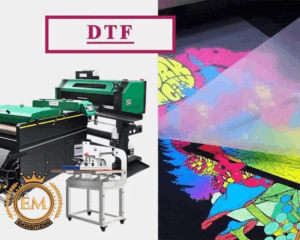

Over the years, the field of printing has witnessed significant advancements, enabling individuals to explore their creativity in various ways. One such innovation that has gained popularity is DTF printing. DTF, short for “Direct to Film,” transfers printer is a digital printing technique that allows users to transfer intricate designs onto fabrics, particularly t-shirts, using a specialized printer and ink.

What is DTF Printing? DTF T-Shirt Printing At Home

What is DTF Film Printing

DTF shirt printing involves a straightforward process of transferring designs onto t-shirts. Unlike traditional methods such as screen printing or heat transfer, direct to film printing near me offers greater flexibility and accuracy in capturing intricate details. The process involves the following steps:

Design Creation:

The initial step in DTF printing is creating or selecting a dtf transfer designs using graphic design software. Users can either design their artwork or download ready-made embroidery designs from various online platforms.

Preparing the Film:

The design is then printed onto a transparent film using a DTF printer. Specialized DTF inks are used, which are formulated to adhere to the fabric.

Applying Adhesive:

Once the design is printed, a layer of adhesive is applied to the film using a DTF powder machine. The adhesive helps the ink adhere to the fabric during the transfer process.

Heat Pressing:

The film with the adhesive layer is placed onto the t-shirt, and the two are heat pressed together. The heat activates the adhesive and allows the ink to transfer onto the fabric.

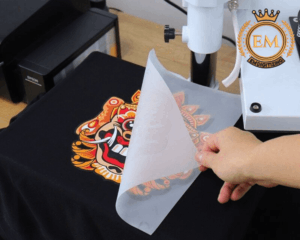

Peeling and Finishing:

After the transfer process, the film is peeled off, revealing the vibrant and detailed design on the t-shirt. A finishing step may be required to cure the ink and enhance its durability.

Advantages of DTF Printing

DTF t shirt printer offers several advantages over traditional t-shirt printing methods, making it an attractive option for individuals looking to create custom designs at home. Here are some notable benefits of DTF heat transfer printer:

Versatility:

Direct to film heat transfer printing allows for the application of intricate and multicolored designs on various fabric types, including cotton, polyester, and blends. It provides greater versatility compared to traditional methods that may be limited in terms of design complexity and fabric compatibility.

High-Quality Output:

DTF transfer printer ensures high-resolution prints with exceptional color vibrancy. The direct transfer process enables accurate reproduction of fine details, gradients, and textures, resulting in visually appealing t-shirt designs.

Durability:

The DTF ink and adhesive combination create a robust bond with the fabric, making the prints resistant to cracking, fading, and peeling. This ensures that the designs maintain their quality and longevity, even after multiple washes.

Cost-Effective:

Direct to fabric transfers printing eliminates the need for expensive screens or vinyl cutters required in traditional methods, making it a cost-effective option for individuals interested in small-scale production or personalized prints.

Easy Setup and Operation:

DTF printing systems are relatively simple to set up and operate, making them accessible to beginners and hobbyists. With minimal equipment and a user-friendly interface, enthusiasts can quickly start creating their own t-shirt designs at home.

Quick Turnaround Time:

DTF printing allows for a fast turnaround time compared to traditional methods. Since there is no need for screen preparation or complex setup, the printing process can be completed quickly. This makes DTF printing suitable for on-demand or time-sensitive projects, such as custom orders or event merchandise.

Full-color Printing:

DTF printing enables the application of full-color designs without limitations. Unlike screen printing, which requires separate screens for each color, DTF printing can reproduce vibrant designs with a wide color gamut in a single print run. This flexibility allows for more creative possibilities and the ability to accurately replicate complex artwork.

Soft and Breathable Prints:

DTF prints have a soft and breathable feel on the fabric. The ink penetrates the fabric fibers, resulting in a print that doesn’t have a heavy or plastic-like texture. This makes DTF printing ideal for creating comfortable and wearable t-shirts that retain the natural feel and drape of the fabric.

Seamless Color Blending:

DTF printing excels in reproducing smooth color gradients and blends. With the ability to print tiny dots of ink, it can create seamless transitions between colors, adding depth and dimension to the designs. This feature is particularly advantageous when printing photorealistic images or designs with intricate shading.

Wide Range of Compatible Fabrics:

DTF printing can be applied to a wide range of fabrics, including cotton, polyester, blends, and even non-textile materials like leather or denim. This versatility allows users to explore different fabric options and expand their creative horizons beyond t-shirts. It opens up possibilities for customizing other textile products such as hoodies, bags, caps, and more.

Eco-Friendly Printing:

DTF printing is considered a more environmentally friendly printing method compared to traditional alternatives. The process doesn’t require water or excess chemicals typically used in screen printing, reducing water waste and environmental pollution. Additionally, DTF inks are often water-based or eco-solvent, further minimizing the ecological impact.

Scalability:

DTF printing offers scalability, allowing users to easily produce small or large quantities of prints. Whether it’s a single custom design or a bulk order, the process remains efficient and consistent. This makes it an attractive option for individuals or small businesses looking to offer personalized t-shirts or launch their own clothing lines.

Considerations for DTF Printing at Home

While DTF printing offers numerous advantages, there are a few considerations to keep in mind when setting up a DTF printing setup at home:

Equipment and Supplies:

DTF printing requires specific equipment, including a DTF printer, DTF inks, a heat press machine, and a DTF powder machine. It is essential to research and invest in reliable and compatible equipment to ensure optimal results.

Workspace and Ventilation:

DTF printing involves working with powders, inks, and adhesives, which may generate fumes and dust particles. Setting up a dedicated workspace with proper ventilation is crucial to ensure a safe and comfortable printing environment.

Learning Curve:

While DTF printing is relatively straightforward, there is still a learning curve associated with achieving the best results. Experimentation, practice, and a willingness to troubleshoot are necessary to master the technique and produce professional-looking prints.

Maintenance and Care:

Regular maintenance of the equipment and proper storage of consumables such as inks and films are essential for prolonging their lifespan and ensuring consistent print quality.

Conclusion:

DTF printing has revolutionized t-shirt printing by providing individuals with an accessible and versatile method to create custom designs at home. The process allows for high-quality prints, intricate details, and vibrant colors, making it an ideal choice for both personal and small-scale production. However, it is crucial to consider the necessary equipment, how to make dtf transfers at home, workspace setup, how to press dtf transfers, and learning curve associated with DTF printing. With the right tools, knowledge, and practice, enthusiasts can unlock their creative potential and transform ordinary t-shirts into unique wearable art. As technology continues to advance, best dtf transfer printer is expected to further evolve, offering even more possibilities for self-expression and customization in the world of textile printing.

If you want to customize embroidery logo digitizing, EM DIGITIZING is the ultimate solution for all your customized embroidery logo digitizing needs. Our company takes pride in delivering top-notch embroidery logo digitizing services with unmatched quality. With our exceptional services, we guarantee to bring your logo to life in a stunning and detailed embroidery design.

At EM DIGITIZING, we understand the importance of customer satisfaction and strive to provide the best possible experience. As a token of appreciation for choosing our services, we offer an incredible 50% discount on all our services to our first-time customers.

Getting started with us is easy. Simply reach out to us for a free quote, and our team will promptly respond and guide you through the process. Thank you for taking out the time to read this article.

When using DTF (Direct-to-Film) printing, you don’t need sublimation paper as it utilizes a different method. DTF transfers are printed on a special film and then transferred onto the fabric using adhesive powder.

DTF ink is specifically designed for the DTF printing process. It’s crucial to use DTF ink that is compatible with your printer model for optimal results and durability.

DTF shirts are known to hold up well in the wash, especially when proper printing and transfer techniques are followed. However, it’s important to follow the care instructions provided with the garment to maintain its longevity.

The type of DTF equipment used can vary depending on the specific requirements of the business. It typically involves a DTF printer, adhesive powder, a heat press machine, and a curing unit to ensure proper transfer and fixation of the design onto the fabric.

The choice of garment for DTF transfers depends on personal preference and the intended embroidery design. DTF can work well on various fabrics, but many prefer using it on cotton or cotton-blend garments for its soft feel and vibrant print results.