Achieving flawless embroidery can feel tricky, but a few simple adjustments can make all the difference. By focusing on specific factors, you can improve embroidery quality and produce professional-level results.

In this article, we’ll explore the key factors that contribute to better embroidery, from proper material choices to mastering your machine settings, ensuring your projects turn out beautifully every time.

12 Important Factors that Improve Embroidery Quality

Factors to Improve Embroidery Quality

Improving the quality of machine embroidery involves attention to several key factors that can greatly influence the final result.

- Needle Sharpness

- Thread Quality

- Upper Thread Tension

- Lower Thread Tension

- Backing Paper Thickness

- Machine Quality

- Framing Tension

- Adherence to Instructions

- Fabric Quality

- Use of Advanced Technology

- Proper Hoop Size

- Stabilizer Removal Technique

Now, let’s take a look at how each of these factors helps improve the quality of your embroidery.

1. Needle Sharpness

A sharp needle is crucial for clean and precise stitching, and it is one of the key factors how to improve quality of machine embroidery. Dull needles can cause fraying and uneven stitches, leading to a poor finish. Regularly changing needles based on the type of fabric being used ensures optimal performance.

Using the correct needle size for the thread and fabric combination is also important. For example, a larger needle is needed for thicker threads and fabrics, while a smaller needle is suitable for finer materials.

2. Thread Quality

High-quality threads are essential for durability and appearance. They should be strong, colorfast, and suitable for the specific fabric. Poor-quality threads can break easily and may not hold their color over time, affecting the overall look of the embroidery.

Using the appropriate thread type for the fabric is crucial to improve embroidery quality. For instance, polyester threads are suitable for most fabrics, while rayon threads provide a shiny finish and are often used for delicate materials.

3. Upper Thread Tension

Proper upper thread tension is vital for balanced stitching. If the tension is too tight, the thread may break; if it’s too loose, the stitches can appear sloppy. Adjusting the tension according to the fabric and thread type helps achieve a smooth finish.

The tension should be tight enough to prevent loops on the underside of the fabric while still allowing the thread to move freely through the needle.

4. Lower Thread Tension

Similar to upper tension, lower thread tension must be correctly set to ensure even stitching. An imbalance can lead to issues like thread bunching or loose stitches on the underside of the fabric.

Fine-tuning both tensions is key to how to improve embroidery quality. The lower thread tension should be slightly tighter than the upper thread tension to maintain a consistent stitch formation.

5. Backing Paper Thickness

The backing material provides support to the fabric during embroidery. Choosing the right thickness prevents distortion and ensures that the stitches hold their shape. A too-thin backing can lead to puckering, while a too-thick backing may be visible through the fabric.

The type of backing material should also be considered, as some are more suitable for specific fabrics. For example, cut-away backing is ideal for knit fabrics, while tear-away backing works well for woven materials.

6. Machine Quality

The quality of the embroidery machine plays a significant role in the final product. High-end machines offer better precision, more features, and improved stitch quality.

Investing in a reliable machine can enhance the overall embroidery experience. Regular maintenance, such as cleaning and oiling the machine, helps ensure optimal performance and extends its lifespan.

7. Framing Tension

Properly framing the fabric ensures that it remains taut during the embroidery process. Loose fabric can lead to uneven stitching and distortions. Using the right hoop and ensuring the fabric is securely held can prevent these issues.

The fabric should be stretched tight enough to prevent sagging but not so tight that it distorts the design or damages the material.

8. Adherence to Instructions

Following the manufacturer’s instructions for both the machine and materials is crucial. This includes settings for tension, speed, and type of needle and thread. Adhering to these guidelines helps avoid common pitfalls that can compromise quality. Experimenting with different settings and techniques can also help improve embroidery skills and produce better results.

9. Fabric Quality

The type and quality of the fabric significantly improve embroidery quality. Fabrics that are too stretchy or too thick can cause complications. Choosing the right fabric that complements the design and thread type is essential for achieving a polished look. Prewashing the fabric to remove any sizing or finishes can also help improve stitch quality and prevent shrinkage after embroidery.

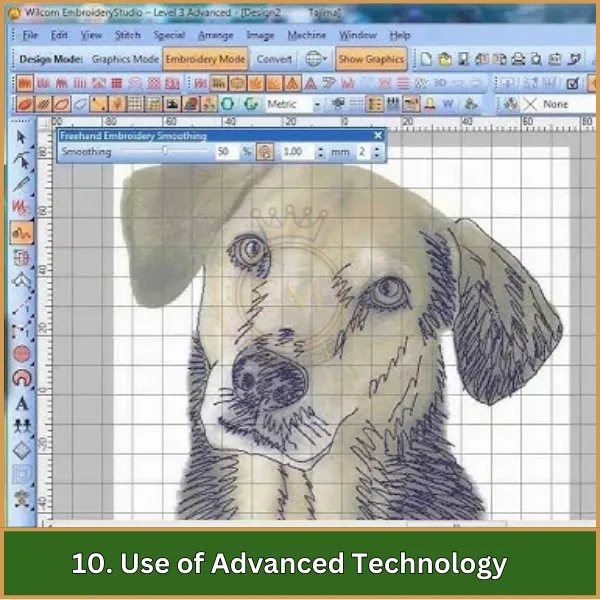

10. Use of Advanced Technology

Incorporating technology such as digitizing software and automated machines can enhance how to improve image quality of machine embroidery. Advanced features allow for more intricate designs and precise stitching. Staying updated with the latest technology can improve efficiency and output quality.

Digitizing software enables the creation of complex designs that can be easily transferred to the embroidery machine, while automated machines ensure consistent stitch quality and speed.

11. Proper Hoop Size

Using the correct hoop size for your fabric and design is crucial. A hoop that is too large may cause the fabric to shift during the embroidery process, leading to misalignment or distortion in the design. A properly fitted hoop ensures that the fabric remains securely in place, resulting in more accurate and consistent stitching.

12. Stabilizer Removal Technique

The way you remove the stabilizer after embroidery can affect the final appearance of the design. Improper removal may cause the fabric to stretch or distort. It’s essential to follow the manufacturer’s instructions for removing the stabilizer—whether cutting away, tearing, or dissolving—to maintain the integrity of both the fabric for the embroidery.

Wrap Up

To truly improve embroidery quality, having a well-digitized design is essential. Even with the best techniques and equipment, poor digitization can hold your projects back.

Before we wrap up, if you need digitizing services, feel free to contact us. We offer affordable digitizing services with guaranteed quality results. We’re offering 50% off to new customers, so grab this amazing deal before it’s too late!

Thank you for reading this article. If you liked it, please share it. You’re on your way to becoming an embroidery pro!

FAQs

Digitizing in embroidery is the process of converting artwork into a digital file that an embroidery machine can read. Good digitizing ensures smooth, accurate stitching, which greatly enhances the quality of the final embroidery.

High-quality thread reduces the chances of breaking and fraying, leading to smoother and more vibrant embroidery. Poor thread quality can result in uneven stitching and a less professional finish.

A stabilizer keeps the fabric steady during embroidery, preventing it from stretching or shifting. This ensures clean, precise stitching and helps maintain the design’s shape and quality.

Complex designs with intricate details can be challenging to embroider and may require more advanced techniques and better digitizing. Simpler designs are generally easier to execute with higher quality.