Ti sei mai chiesto?, “Cos’è la serigrafia?"È un modo divertente e creativo per stampare disegni su materiali come il tessuto, carta, e altro ancora. Questa tecnica funziona utilizzando uno stencil su un retino per trasferire l'inchiostro, dare vita alle tue idee.

La serigrafia è ampiamente amata per i suoi colori vivaci e i risultati duraturi, ecco perché viene spesso utilizzato per le magliette personalizzate, manifesti, e altri oggetti unici.

In questa guida, ti guideremo attraverso l'intero processo in semplici passaggi. Che tu sia nuovo alla stampa serigrafica o desideri migliorare le tue capacità, questa guida ti aiuterà a comprendere le nozioni di base e ad avviare il tuo progetto di stampa. Immergiamoci!

Cos'è la serigrafia? Una guida completa

Comprendere la stampa serigrafica

Serigrafia, spesso indicato come serigrafia, è un metodo in cui l'inchiostro viene trasferito con cura attraverso uno schermo a rete che contiene uno stencil. Questo processo dà vita a disegni complessi su un’ampia gamma di materiali, compreso il tessuto, carta, plastica, e perfino il vetro. È una tecnica versatile e creativa utilizzata per realizzare stampe dettagliate su varie superfici.

Tipi di tecniche di serigrafia

Serigrafia è una forma d'arte versatile con numerosi tipi di serigrafia che soddisfano esigenze e visioni creative diverse. Ogni metodo è unico nel suo processo e nei risultati che offre, offrendo infinite possibilità di personalizzazione su vari materiali.

- Serigrafia tradizionale: Questo metodo classico utilizza un retino e uno stencil per trasferire l'inchiostro su materiali come il tessuto, carta, o plastica. È una tecnica pratica per progetti puliti e precisi.

- Serigrafia a base acqua: Una scelta eco-consapevole, questo metodo utilizza inchiostri a base d'acqua che penetrano nei tessuti, creando morbidezza, stampe traspiranti perfette per l'abbigliamento.

- Serigrafia a scarica: Ideale per tessuti scuri, questo metodo utilizza un agente scaricante per rimuovere il colorante dal materiale, risultando vibrante, disegni effetto sbiancato.

- Serigrafia plastisol: Conosciuto per i suoi colori audaci e la sua longevità, Gli inchiostri plastisol si trovano sulla parte superiore del materiale e sono polimerizzati a caldo per garantirne la durata.

- Serigrafia metallica: Questo metodo utilizza inchiostri metallici per aggiungere un effetto riflettente, finitura lucida, spesso utilizzato per far risaltare abbigliamento e articoli promozionali.

- Serigrafia UV: Progettato per un'asciugatura rapida e risultati di alta qualità, questa tecnica utilizza inchiostri essiccabili ai raggi UV che vengono induriti sotto la luce ultravioletta, adatto per vetro, metallo, e superfici in plastica.

- Serigrafia ad alta densità: Per un effetto 3D, vengono applicati spessi strati di inchiostro per creare disegni in rilievo, aggiungendo consistenza e dimensione alla stampa.

- Serigrafia completa: Chiamata anche stampa jumbo, questa tecnica consente disegni a copertura totale, rendendolo ideale per stampe audaci su capi di grandi dimensioni come magliette e felpe con cappuccio.

Cos'è la serigrafia; è più di un semplice metodo di stampa; è uno strumento versatile per creare colpi di scena, disegni personalizzati. Ciascuna tecnica offre un modo unico per esplorare ciò che la serigrafia può ottenere, dai dettagli intricati all'audace, modelli all-over.

Materiali e strumenti necessari per la serigrafia

Gli strumenti di serigrafia sono la spina dorsale di questo processo creativo, garantendo che ogni passaggio sia fluido e preciso. Dalla preparazione dello schermo alla cura del progetto finale, avere gli strumenti giusti è essenziale per il successo.

- Schermo a maglie

- Tergipavimento

- Emulsione fotografica

- Unità di esposizione

- Dispositivo per la rimozione delle emulsioni

- Stazione di lavaggio

- Inchiostri da stampa

- Substrati

- Software di progettazione grafica

- Nastro di screening

- Attrezzature per la polimerizzazione a caldo

- Attrezzatura di registrazione

- Spazzole e stracci per la pulizia

- Pellicola trasparente o stencil

1. Schermo a maglie

La spina dorsale della serigrafia, uno schermo a rete è teso saldamente su un telaio, fungendo da base per il trasferimento dell'inchiostro sul substrato.

2. Tergipavimento

Uno strumento indispensabile con una lama piatta in gomma, la spatola distribuisce l'inchiostro in modo uniforme sullo schermo, premendolo attraverso la mesh per creare il disegno.

3. Emulsione fotografica

Questo liquido sensibile alla luce viene applicato sullo schermo a maglie per creare uno stencil. Quando esposto alla luce, si indurisce in aree specifiche, lasciando il disegno pronto per la stampa.

4. Unità di esposizione

Questo dispositivo utilizza la luce UV per esporre lo schermo rivestito in emulsione, consolidare le aree non coperte dal progetto, formando uno stampino preciso.

5. Dispositivo per la rimozione delle emulsioni

Una soluzione chimica che aiuta a pulire l'emulsione fotografica dallo schermo dopo l'uso, rendere lo schermo riutilizzabile per nuovi progetti.

6. Stazione di lavaggio

Un'area attrezzata con strumenti a pressione d'acqua per il risciacquo e la pulizia dello schermo dopo l'esposizione, assicurando che il disegno sia chiaramente visibile e pronto per la stampa.

7. Inchiostri da stampa

Per dare vita ai disegni vengono utilizzati inchiostri serigrafici appositamente formulati, come plastisol o a base acqua. Ogni tipo offre vantaggi unici, come colori vivaci o eco-compatibilità.

8. Substrati

Questi sono i materiali su cui vengono stampati i disegni, compreso il tessuto, carta, metallo, legna, o plastica, a seconda dei requisiti del progetto.

9. Software di progettazione grafica

Programmi come Adobe Illustrator o CorelDRAW sono essenziali per creare e modificare la grafica da trasferire sullo schermo.

10. Nastro di screening

Utilizzato per bloccare le aree indesiderate sullo schermo, il nastro schermante garantisce che l'inchiostro passi solo attraverso le parti della rete destinate al disegno.

11. Attrezzature per la polimerizzazione a caldo

Dopo la stampa, Per fissare l'inchiostro è necessaria un'attrezzatura di polimerizzazione come un essiccatore flash o una pressa a caldo, garantendo durata e resistenza all'usura.

12. Attrezzatura di registrazione

Questi strumenti garantiscono l'allineamento perfetto di più schermi stampe multicolori, mantenendo l’accuratezza e la precisione del progetto.

13. Spazzole e stracci per la pulizia

Per la manutenzione e la pulizia, spazzole e stracci sono essenziali per mantenere gli schermi, racle, e spazi di lavoro in ottime condizioni.

14. Pellicola trasparente o stencil

Utilizzato per creare stencil, questa pellicola blocca la luce in aree specifiche durante l'esposizione, assicurando che il disegno venga trasferito accuratamente sullo schermo.

Cos'è la serigrafia: Guida passo passo

La serigrafia è un processo creativo che trasforma i disegni in stampe di alta qualità. Ogni passaggio gioca un ruolo cruciale nel raggiungimento di un risultato impeccabile. Immergiamoci nel processo:

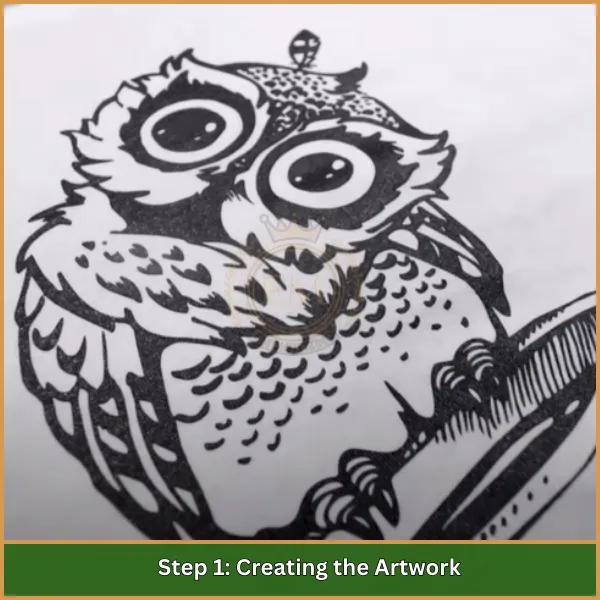

Fare un passo 1: Creazione dell'opera d'arte

Il viaggio inizia con la progettazione dell'opera d'arte. Per creare l'immagine viene utilizzato un software di progettazione grafica, che viene poi stampato su una pellicola trasparente che funge da stencil.

Fare un passo 2: Preparazione dello schermo

Uno schermo a maglie viene scelto in base alle esigenze del progetto. È rivestito con uno strato di emulsione fotosensibile, che pone le basi per la creazione dello stencil.

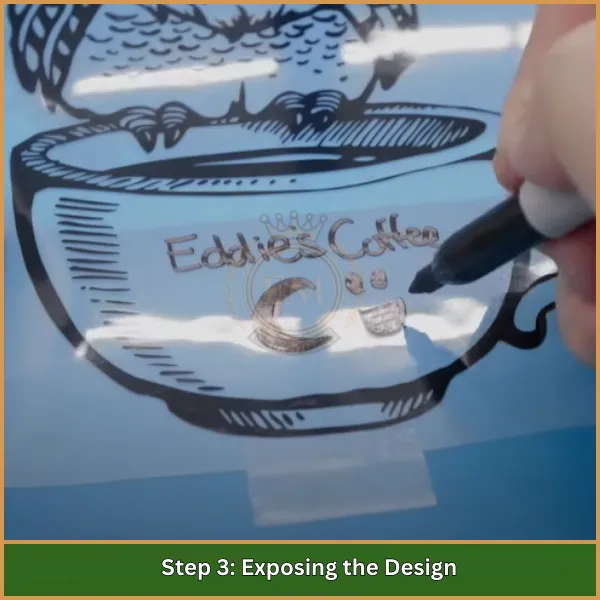

Fare un passo 3: Esporre il disegno

La pellicola trasparente con il disegno viene posizionata sullo schermo emulsionato. L'esposizione alla luce UV indurisce l'emulsione nelle aree scoperte, lasciando morbide le porzioni del disegno.

Fare un passo 4: Risciacquo dello schermo

Dopo l'esposizione, lo schermo viene lavato con acqua per eliminare l'emulsione ammorbidita. Questo passaggio rivela lo stencil, che consentirà all'inchiostro di passare durante la stampa.

Fare un passo 5: Impostazione dell'attrezzatura

Lo schermo è posizionato saldamente su una macchina da stampa, e il materiale (tessuto, carta, eccetera.) è allineato sotto di esso. Una corretta configurazione è essenziale per garantire una stampa precisa.

Fare un passo 6: Applicazione dell'inchiostro

L'inchiostro viene versato a un'estremità dello schermo, e viene utilizzata una spatola per spingerla uniformemente sullo stencil. L'inchiostro si trasferisce attraverso le aree aperte, dare vita al disegno sul materiale.

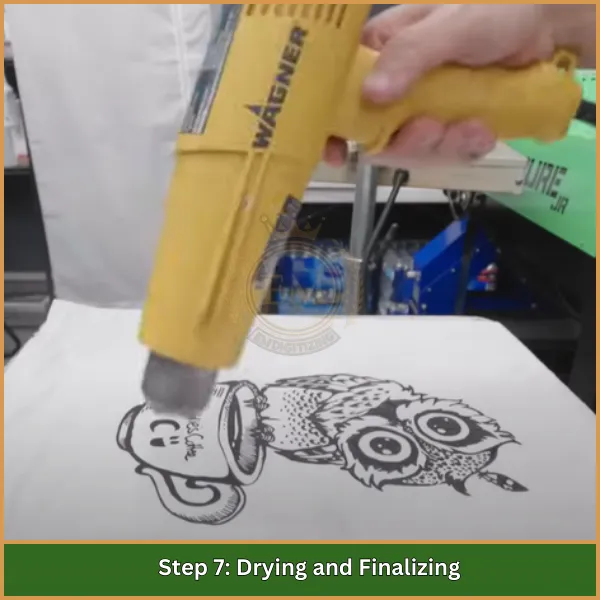

Fare un passo 7: Asciugatura e Finalizzazione

L'oggetto stampato viene spostato in una stazione di polimerizzazione dove viene applicato il calore per asciugare e fissare l'inchiostro. Ciò garantisce che il design sia durevole e resistente all'usura. Dopo un controllo di qualità, il prodotto è pronto per l'uso o la distribuzione.

Suggerimenti essenziali per una serigrafia di successo

- Mantieni pulito il tuo spazio di lavoro: Un ambiente privo di polvere garantisce che le tue stampe risultino nitide e impeccabili, minimizzando gli errori.

- Utilizza stencil di qualità: Gli stencil ben preparati con uno strato di emulsione liscio risultano nitidi, disegni professionali.

- Scegli il numero di mesh corretto: Match the screen mesh to your design’;s dettaglio. Utilizzare conteggi inferiori per inchiostri spessi e conteggi superiori per motivi complessi.

- Allinea perfettamente gli schermi: La corretta registrazione è fondamentale per le stampe multicolore. Assicurati che tutti gli schermi siano allineati per evitare disegni sovrapposti o disallineati.

- Mescolare accuratamente gli inchiostri: Gli inchiostri costantemente miscelati forniscono colori uniformi e un'applicazione uniforme, migliorando la qualità complessiva.

- Indurimento flash tra i colori: La polimerizzazione breve di ciascun colore previene le sbavature e garantisce una pulizia, look a strati per stampe multicolori.

- La polimerizzazione stampa correttamente: Una corretta polimerizzazione a caldo aumenta la durata e previene lo sbiadimento o la rottura delle stampe.

- Eseguire una stampa di prova: Controlla sempre una stampa di prova per individuare eventuali problemi prima di iniziare il ciclo di produzione completo.

Conclusione

Ora hai imparato cos'è la serigrafia e come dà vita ai disegni sul tessuto, carta, e altro ancora. È un processo creativo che chiunque può padroneggiare con gli strumenti e le tecniche giuste.

Per rendere i tuoi progetti di serigrafia ancora più semplici, EMDigitalizzazione è qui per aiutarti! Offriamo servizi professionali di arte vettoriale ai migliori prezzi, garantendo consegne veloci e qualità senza pari. Più, puoi visualizzare l'anteprima del tuo progetto prima che sia finalizzato, quindi sai esattamente cosa aspettarti.

Se ci stai provando per la prima volta, ecco un'offerta esclusiva: Ottenere 50% spento il tuo primo ordine! Che tu stia iniziando un nuovo progetto o una nuova esigenza disegni di alta qualità, EMdigitizing è il tuo partner di fiducia.

Domande frequenti

La serigrafia è una tecnica classica in cui l'inchiostro viene pressato attraverso uno schermo a rete per creare disegni dettagliati su varie superfici come il tessuto, carta, e plastica.

La serigrafia sulle magliette prevede l'utilizzo di uno stencil e di uno schermo a rete per trasferire l'inchiostro sul tessuto, dando vita a design vivaci e duraturi.

Per la serigrafia di magliette, avrai bisogno di oggetti come uno schermo a maglie, stampino, tergipavimento, inchiostri da stampa, e un dispositivo di polimerizzazione. Sono utili anche strumenti aggiuntivi come emulsione e prodotti per la pulizia.

Le tecniche di stampa serigrafica includono quelle tradizionali, a base d'acqua, scarico, plastisol, metallico, Stampa UV, e altro ancora, ciascuno offre risultati unici per varie applicazioni.