Vous êtes-vous déjà demandé comment les rendre dynamiques, des designs durables qui ressortent sur les vêtements et les accessoires? Les patchs de sublimation sont le secret! Ils sont parfaits pour ajouter une touche unique à vos tenues ou promouvoir votre entreprise avec style.

Dans ce guide, Nous décomposons tout ce que vous devez savoir sur ces correctifs - de ce qu'ils sont à la façon dont vous pouvez les créer vous-même. Que vous soyez un débutant ou que vous recherchiez de nouvelles idées créatives, Ils sont une façon passionnante de donner vie à vos créations.

Explorons leur magie ensemble!

Un guide complet sur les patchs de sublimation

Que sont les patchs de sublimation?

Ce sont des correctifs conçus sur mesure à travers le processus d'impression de sublimation. Cette technique utilise la chaleur et la pression pour transférer les conceptions du papier sublimation sur des tissus spécialement enduits, Créer des vibrants, longue durée, et des impressions très détaillées qui sont intégrées en permanence dans le matériau.

Quels sont les types de patchs de sublimation?

Les correctifs sont disponibles dans de nombreux types fabriqués en utilisant le processus de sublimation. Chaque type a des fonctionnalités uniques pour différents besoins.

- Patchs en polyester

- Patchs à la chaleur adhésifs

- Patchs en feutre

- Patchs tissés

- Patchs de forme personnalisés

1. Patchs en polyester

Les patchs en polyester sont un choix populaire en raison de leur durabilité et de leur compatibilité avec l'impression de sublimation. Ces patchs sont fabriqués à partir de tissu de polyester de haute qualité, qui permet dynamique, conceptions haute résolution. Ils sont légers et fonctionnent bien pour les vêtements et les accessoires, les rendre polyvalents pour diverses utilisations comme les vêtements de sport et les articles promotionnels.

2. Patchs à la chaleur adhésifs

Les patchs à chaleur adhésifs sont conçus avec un support spécial sensible à la chaleur qui se lie facilement aux tissus lorsqu'il est pressé avec de la chaleur. Ces correctifs sont idéaux pour une application rapide et efficace, Souvent utilisé pour les uniformes, Sacs, ou projets de bricolage. L'adhésif fort garantit que le patch reste en toute sécurité après l'application, Fournir une finition propre et professionnelle.

3. Patchs en feutre

Les patchs en feutre ont un doux, Surface texturée qui leur donne une apparence unique et classique. Leur matériel détient bien les impressions de sublimation, résultant en gras, des designs accrocheurs. Ces patchs sont idéaux à des fins décoratives et sont couramment utilisés sur les chapeaux, vestes, ou comme articles à collectionner.

4. Patchs tissés

Patchs tissés sont fabriqués à partir de fils tissés étroitement qui créent une surface lisse et détaillée. Cela permet des conceptions complexes, Texte fin, et les logos à représenter clairement. Les patchs tissés sont parfaits pour la marque professionnelle, Logos d'entreprise, et des œuvres d'art détaillées, offrant un look élégant et poli.

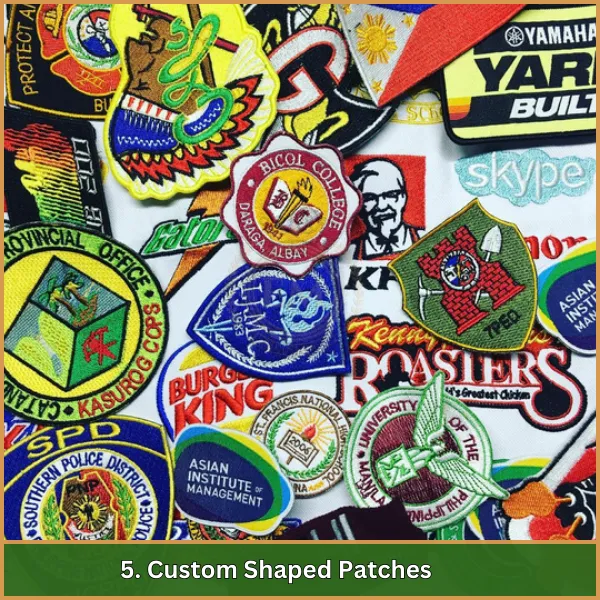

5. Patchs de forme personnalisés

Les correctifs de forme personnalisés sont adaptés pour répondre aux besoins de conception spécifiques, leur permettant d'être coupés en n'importe quelle forme ou taille. Cette flexibilité les rend idéales pour une marque unique, événements spéciaux, ou personnalisation créative. Que ce soit pour une utilisation promotionnelle ou des projets personnels, Ces correctifs aident les conceptions à se démarquer avec leurs formes distinctives et leurs impressions vibrantes.

Quels sont les avantages des patchs sublimés?

Ils sont très durables et fournissent dynamique, Designs détaillés qui ne se décoloreront pas ou ne peleront pas au fil du temps. Leur nature légère et personnalisable les rend adaptés à une variété d'applications, De la marque aux projets personnels.

- Designs vibrants et détaillés: Offre des imprimés de haute qualité avec des détails pointus et des couleurs vives.

- Résistant à la fondu: La sublimation intègre le design dans le tissu, assurer la longévité.

- Options personnalisables: Disponible en différentes formes, tailles, et des conceptions pour répondre aux besoins spécifiques.

- Léger: Ajoute un minimum, Les rendre idéaux pour les vêtements et les accessoires.

- Rentable: Abordable pour les petits et les grands cycles de production.

- Respectueux de l'environnement: Il utilise moins d'encre et d'énergie que les autres méthodes d'impression.

Quelles sont les limites des correctifs sublimés?

Ils sont populaires, Mais ils ont quelques limites. Comprenez-les pour prendre une décision éclairée lors du choix de la sublimation pour votre projet.

- Restrictions relatives aux tissus: Ils fonctionnent mieux sur le polyester ou les matériaux enduits, les rendre inadaptés aux tissus comme le coton.

- Sensibilité à la chaleur: Les températures élevées requises pour l'impression sublimation peuvent endommager les articles sensibles à la chaleur, y compris des matériaux de chapeau.

- Limitations de couleur: Les patchs de sublimation pour les chapeaux peuvent ne pas être aussi vibrants sur les tissus sombres ou non blancs, Comme le processus repose sur une base de couleur claire.

- Usure normale: Bien que durable, frottement ou flexion continue, Surtout sur des articles fréquemment utilisés comme des chapeaux, can affect the patch’;S La durée de vie.

- Coûts initiaux élevés: Investir dans des imprimantes sublimation et des presses à chaleur peut être coûteuse pour les projets à petite échelle ou débutants.

Quels matériaux sont nécessaires pour les correctifs de broderie sublimation?

Vous avez besoin d'outils et de matériaux spécifiques conçus pour le processus de sublimation pour créer ces correctifs. Ceux-ci garantissent des résultats de haute qualité avec des conceptions dynamiques et durables.

- Patchs de sublimation vierges: Patchs précoés prêts pour l'impression de sublimation.

- Imprimante à sublimation: Pour les conceptions d'impression sur du papier sublimation.

- Encre sublimation: Encre spécialisée utilisée pour transférer des conceptions.

- Papier sublimation: Papier résistant à la chaleur pour transporter la conception imprimée.

- Machine à chaleur: Applique la chaleur et la pression pour le transfert de conception.

- Feuille de protection: Téflon ou papier parchemin pour protéger le tissu et la presse à chaleur.

- Ruban résistant à la chaleur: Pour maintenir le design en place pendant la pression.

- Outils de coupe: Ciseaux ou machines de coupe pour façonner les patchs au besoin.

- Logiciel de conception: Pour créer et personnaliser les conceptions de patchs.

Processus étape par étape pour faire des correctifs de sublimation

- Préparez vos matériaux: Rassembler des matériaux comme des patchs sublimés, imprimantes de sublimation, encre sublimation, papier sublimation, machines à chaleur, et ruban soumis à la chaleur.

- Créez votre conception: Utilisez un logiciel de conception pour créer votre œuvre. Pour des patchs de chapeau de sublimation personnalisés ou d'autres conceptions, Zdigizing offre des services d'experts pour assurer la perfection.

- Imprimez la conception: Imprimez votre conception sur du papier sublimation à l'aide d'une imprimante de sublimation. N'oubliez pas de refléter le design avant d'imprimer.

- Positionnez la conception sur le patch: Placer le papier sublimation sur le patch de sublimation vierge avec le côté imprimé face vers le bas. Utilisez du ruban à la chaleur pour le fixer.

- Configurez la presse à chaleur: Préchauffer la chaleur appuyez sur 380 ° F-400 ° F et ajustez la pression au besoin.

- Appuyez sur le patch: Couvrir le patch avec une feuille de protection et appuyer sur la chaleur pour la chaleur pour 40-60 secondes.

- Refroidir le patch: Retirez soigneusement le papier sublimation et laissez le patch refroidir complètement.

- Couper et finir: Coupez le patch dans la forme souhaitée, si nécessaire, et assurer que la conception est parfaitement transférée.

Ces étapes vous aideront à faire de superbes patchs de chapeau sublimation ou d'autres patchs sublimés vibrants pour vos projets!

Applications des correctifs de sublimation

Les patchs en cuir sublimation sont parfaits pour ajouter un look élégant et professionnel à divers articles. Leur durabilité et leur sensation de prime les rendent idéaux pour la marque et la personnalisation.

- Vêtements en cuir personnalisés: Utilisé sur les vestes, Sacs, Et des chapeaux pour un élégant, design professionnel.

- Marque de marque: Parfait pour les produits promotionnels haut de gamme comme les portefeuilles en cuir ou les casquettes.

- Articles de cadeaux de luxe: Ajoute une touche premium aux cadeaux personnalisés pour des occasions spéciales.

- Accessoires et décoration: Idéal pour les portefeuilles, porte-clés, ou pièces de décoration intérieure avec un design personnalisé.

- Marchandises d'événement: Idéal pour les souvenirs haut de gamme ou les correctifs commémoratifs pour des événements spéciaux.

- Projets de passe-temps et d'artisanat: Une façon amusante pour les amateurs de bricolage de concevoir et de créer des patchs décoratifs.

- Objets de collection de patch: Populaire parmi les collectionneurs pour la création de correctifs de collection uniques et dynamiques.

- Réparation des vêtements: Couvre des larmes ou des trous dans les vêtements tout en ajoutant une touche décorative.

Il offre des conceptions de polyvalence et de dynamisme, en faisant un choix populaire dans diverses applications!

Conclusion

Les patchs de sublimation sont un moyen amusant et facile d'ajouter coloré, Designs durables à vos articles. Avec un peu de pratique, Vous pouvez créer des patchs incroyables qui ont l'air professionnels et rester vibrants pendant des années.

Que vous fassiez des correctifs pour vous-même, comme cadeaux, ou pour votre entreprise, Ils sont un projet créatif et enrichissant. Si vous avez besoin d'aide pour créer un design de haute qualité pour votre patch, nous sommes là pour vous aider! Chez EMdigitizing, nous offrons services de vectorisation professionnels à la moitié du prix du marché, et les nouveaux clients peuvent profiter d'un 50% rabais.

Commencez votre voyage de correctif aujourd'hui et laissez-nous vous aider à donner vie à vos idées!

FAQ

Oui, La sublimation peut être effectuée sur des patchs en cuir, Mais il fonctionne mieux sur le cuir qui a un revêtement spécial ou qui est traité d'un spray sublimation pour maintenir efficacement la conception.

Pour créer ces patchs pour les chapeaux, Imprimez votre conception sur du papier sublimation avec encre sublimation. Transférer la conception sur un matériau de patch prêt pour la sublimation à l'aide d'une presse à chaleur. Alors, Fixez le patch au chapeau en coudant ou en appliquant un support adhésif.