Encontrar el La mejor tela para serigrafía. es el primer paso para crear diseños increíbles. El tipo de tela que elijas puede afectar el aspecto de la tinta., se siente, y perdura en el tiempo. Algunas telas facilitan el proceso y ofrecen resultados más nítidos., mientras que otros pueden no funcionar tan bien.

En este articulo, Exploraremos las telas ideales para serigrafía.. Descubrirá sus características únicas y cómo pueden ayudarle a lograr impresiones de alta calidad.. Ya sea que estés trabajando en camisetas, bolsas, u otros artículos, conocer el tejido adecuado marca la diferencia. Vamos a sumergirnos!

¿Cuáles son las mejores telas para serigrafía??

Explorando la mejor tela para serigrafía

Encontrar el mejor tejido para serigrafía puede marcar una diferencia significativa en la calidad de tus impresiones.. Aquí hay una lista de tipos de telas que funcionan bien para impresión de pantalla proyectos:

- Seda

- Algodón

- Lino

- Lana

- Nylon

- Poliéster

- Spandex

- Cáñamo

1. Seda

La seda es un tejido lujoso conocido por su suavidad., textura suave, lo que la convierte en la mejor opción para proyectos de serigrafía de alta gama.. Su capacidad para producir diseños refinados y elegantes lo hace ideal para prendas y accesorios de lujo..

Beneficios:

- La superficie lisa permite impresiones intrincadas y detalladas..

- Naturalmente resistente a las manchas, manteniendo su calidad en el tiempo.

Limitaciones:

- La absorción limitada de tinta puede resultar en una impresión más suave., colores menos vibrantes.

- Caro y menos duradero, haciéndolo inadecuado para la impresión masiva.

2. Algodón

El algodón es un tejido versátil y muy utilizado en serigrafía. Sus fibras naturales absorben la tinta de manera eficiente., produciendo diseños vibrantes y duraderos. Es una excelente opción para ropa diaria y personalizada..

Beneficios:

- Excelente retención de tinta para nítidos., estampados coloridos.

- Respirable, cómodo, y ampliamente disponible en diferentes tejidos.

Limitaciones:

- Propenso a encogerse y arrugarse después del lavado..

- Tiempo de secado más lento en comparación con los tejidos sintéticos..

3. Lino

El lino ofrece una superficie natural y texturizada., proporcionando una estética rústica y ecológica para diseños serigrafiados. Su naturaleza transpirable lo hace perfecto para uso liviano y casual..

Beneficios:

- La textura única añade un carácter distintivo a los diseños..

- Ecológico y muy transpirable., ideal para prendas de verano.

Limitaciones:

- La superficie irregular puede dificultar la impresión.

- Puede requerir un tratamiento previo para obtener resultados consistentes.

4. Lana

La lana es un tejido más grueso que proporciona una excelente absorción de tinta., dando como resultado impresiones ricas y atrevidas. A menudo se elige para ropa de invierno o proyectos que requieren materiales duraderos..

Beneficios:

- Retiene bien la tinta, permitiendo colores profundos y vibrantes.

- Durable y naturalmente aislante, ideal para climas más fríos.

Limitaciones:

- La textura rugosa dificulta la obtención de impresiones uniformes.

- Puede encogerse o sentirse bajo el calor y la humedad..

5. Nylon

El nailon es un tejido sintético resistente y ligero., comúnmente utilizado en ropa deportiva. Su elasticidad y superficie lisa pueden producir impresiones nítidas., pero requiere un manejo cuidadoso.

Beneficios:

- Ligero y elástico, ideal para ropa deportiva y exterior.

- Buena resistencia a la humedad, perfecto para aplicaciones al aire libre.

Limitaciones:

- La adhesión de la tinta puede ser complicada en su superficie lisa..

- Propenso a derretirse a altas temperaturas durante el proceso de curado..

6. Poliéster

El poliéster es un tejido duradero y resistente a la humedad que se utiliza a menudo en la serigrafía comercial.. Su textura suave garantiza impresiones claras y vibrantes., haciéndolo ideal para prendas promocionales y deportivas..

Beneficios:

- Mantiene la intensidad del color incluso después de múltiples lavados..

- Resistente a las arrugas y muy duradero..

Limitaciones:

- Sensible al calor alto, que puede causar daños durante la impresión.

- A menudo requiere mezclarse con algodón para obtener una calidad de impresión óptima..

7. Spandex

El spandex es un tejido elástico y flexible que se utiliza para prendas deportivas y ajustadas.. Si bien agrega comodidad, su elasticidad puede plantear desafíos para la serigrafía.

Beneficios:

- La alta elasticidad garantiza un ajuste cómodo para las prendas..

- Perfecto para diseños de rendimiento y ropa deportiva..

Limitaciones:

- La tinta puede agrietarse o distorsionarse cuando la tela se estira..

- Requiere técnicas especiales para garantizar impresiones duraderas..

8. Cáñamo

El cáñamo es un tejido sostenible y ecológico conocido por su durabilidad.. Sus fibras naturales proporcionan una textura rústica que complementa diseños informales y terrosos..

Beneficios:

- Fuerte y duradero, ideal para uso repetido.

- Respetuoso con el medio ambiente, con mínimo impacto en el planeta.

Limitaciones:

- Disponibilidad limitada en comparación con el algodón o el poliéster..

- Puede sentirse áspero en la piel a menos que se mezcle con materiales más suaves..

Factores clave de las telas perfectas para serigrafía

A la hora de seleccionar la mejor tela para serigrafía, ciertas características garantizan resultados duraderos y de alta calidad. Estas son las características esenciales a considerar.:

- Fuerte durabilidad

- Excelente absorción de tinta

- Alta calidad de impresión y nitidez

- Resistencia al calor

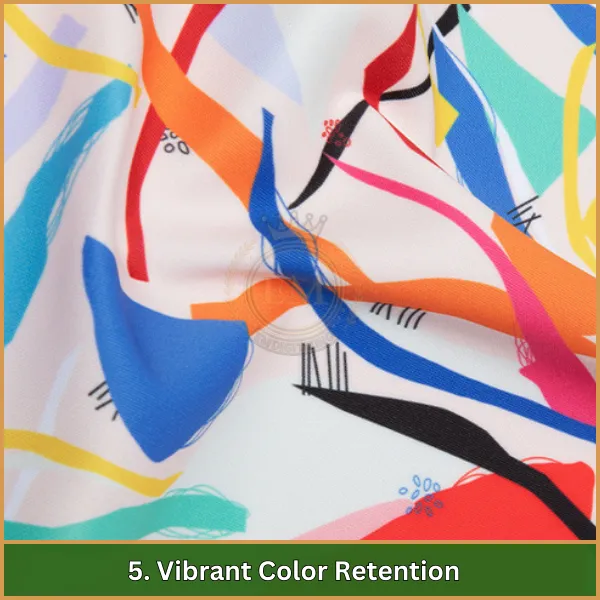

- Retención de color vibrante

- Gestión eficaz de la humedad

- Textura suave y compatible

- Sensación cómoda y transpirable

1. Fuerte durabilidad

Los tejidos duraderos garantizan impresiones duraderas que resisten lavados frecuentes., tener puesto, y exposición a diversas condiciones. Esto los hace ideales para la ropa diaria., casa de textiles, y otros artículos de uso frecuente.

2. Excelente absorción de tinta

Las telas con alta absorción de tinta producen colores vibrantes., diseños nítidos. Esta característica evita que los colores se desvanezcan o se destiñan., garantizar que las impresiones sigan siendo llamativas y llamativas con el tiempo.

3. Alta calidad de impresión y nitidez

Una superficie de tela suave permite líneas nítidas e imágenes detalladas.. Esto garantiza que los diseños complejos e intrincados se trasladen perfectamente al material., mejorar el atractivo estético general.

4. Resistencia al calor

Las telas resistentes al calor pueden soportar el proceso de curado sin derretirse ni distorsionarse.. Esta propiedad garantiza que la tela mantenga su integridad mientras la tinta se fija., dando como resultado un producto final impecable.

5. Retención de color vibrante

La capacidad de retener colores brillantes y saturados hace que una tela sea ideal para serigrafía.. Garantiza que los diseños sigan siendo vívidos e impactantes incluso después de un uso prolongado..

6. Gestión eficaz de la humedad

Los tejidos con buena capacidad de absorción de la humedad mantienen a los usuarios cómodos al alejar el sudor del cuerpo.. Esta característica es especialmente importante para ropa deportiva y ropa para exteriores..

7. Textura suave y compatible

La textura de un tejido juega un papel clave en el éxito de la serigrafía. Las telas suaves permiten una distribución y adherencia uniforme de la tinta., proporcionando consistente, resultados de calidad profesional.

8. Sensación cómoda y transpirable

Los tejidos transpirables promueven la circulación del aire y reducen la acumulación de humedad., hacerlos cómodos de usar. Esto es esencial para prendas diseñadas para uso diario o deportivo..

Explorando la compatibilidad de telas con técnicas de impresión

El éxito de la serigrafía y otros métodos depende en gran medida de la elección del tejido adecuado.. Cada técnica de impresión interactúa de manera diferente con varios materiales., por lo que comprender la compatibilidad es esencial. Ya sea que esté buscando el La mejor tinta textil para serigrafía. u otros métodos, así es como combinan con tipos de telas populares.

1. Impresión de pantalla

Una técnica clásica en la que la tinta se empuja a través de una plantilla sobre la tela y se fija con calor., haciéndolo perfecto para diseños atrevidos y grandes cantidades.

Las mejores telas: Algodón, poliéster, triples mezclas

Por qué funciona: El algodón absorbe la tinta maravillosamente para impresiones vibrantes., El poliéster garantiza durabilidad y resistencia a la humedad., y las mezclas triples ofrecen una sensación suave con una retención de tinta equilibrada.

2. Directo a la prenda (DTG) Impresión

Usando tecnología avanzada de inyección de tinta, Impresiones DTG directamente sobre telas., capturando detalles finos y colores vivos, haciéndolo ideal para diseños personalizados y lotes más pequeños.

Las mejores telas: 100% algodón o mezclas de algodón

Por qué funciona: Las fibras de algodón absorben la tinta de manera eficiente, asegurando diseños nítidos y detallados con resultados de alta resolución.

3. Tintas a base de agua

Popular por su acabado ecológico y transpirable., Las tintas a base de agua crean suaves, impresiones de sensación natural, comúnmente utilizado en serigrafía y DTG.

Las mejores telas: Mezclas de algodón y algodón.

Por qué funciona: Estas tintas se adhieren bien a fibras naturales como el algodón., produciendo diseños suaves al tacto con excelente transpirabilidad.

4. Tintas Plastisol

Una opción gruesa y duradera, Las tintas plastisol se curan con calor para producir colores vibrantes., diseños duraderos, a menudo se prefiere para serigrafías llamativas y brillantes.

Las mejores telas: Algodón, poliéster, mezclas

Por qué funciona: Plastisol se adhiere fuertemente tanto a fibras naturales como sintéticas., ofreciendo resultados consistentes y duraderos en diferentes tipos de telas.

5. Impresión por sublimación

Usando calor y presión, La sublimación transforma el tinte en gas., uniéndolo permanentemente con telas sintéticas, creando diseños vivos y resistentes a la decoloración.

Las mejores telas: Materiales recubiertos de poliéster y polímero.

Por qué funciona: El poliéster absorbe profundamente el tinte., resultando en brillante, diseños permanentes que resisten la decoloración y el desgaste.

6. Impresión por transferencia

Este método consiste en aplicar diseños preimpresos a la tela mediante prensas térmicas., convirtiéndolo en una opción versátil para una variedad de proyectos.

Las mejores telas: Algodón, poliéster, mezclas

Por qué funciona: Telas que pueden soportar el calor de manera efectiva, como mezclas de algodón y poliéster, Proporciona una superficie lisa para transferencias precisas y duraderas..

Consejos para probar y preparar telas para serigrafía

Para conseguir estampados impecables con el mejor tejido para impresión de pantalla, preparar tus materiales es fundamental. Siga estos pasos para asegurarse de que su tela esté lista para imprimir y brinde resultados de alta calidad.:

- Prelavar la tela: Quitar cualquier suciedad, quimicos, o tallaje lavando la tela previamente. Esto ayuda a que las tintas se adhieran mejor..

- Realizar una prueba de tinta: Pruebe con una pequeña impresión de prueba para comprobar qué tan bien se adhiere la tinta a la tela y si los colores parecen vibrantes..

- Evaluar el peso de la tela: Determine si el peso de la tela se adapta al método de impresión elegido; las telas más claras pueden necesitar técnicas o tintas especiales..

- Verificar la textura de la superficie: Las telas lisas suelen dar como resultado impresiones más nítidas., así que evalúa la textura antes de comenzar..

- Seleccione la composición adecuada: Haga coincidir el tipo de tela con su método de impresión, como algodón para DTG o poliéster para sublimación.

- Realizar una prueba de estiramiento: Estire la tela para ver si la tinta permanece intacta sin agrietarse ni distorsionarse..

- Prueba de tolerancia al calor: Verifique que la tela pueda soportar temperaturas de curado sin daños ni distorsiones..

- Elija la emulsión adecuada: Utilice una emulsión que se alinee con su tipo de tela y técnica de impresión para una exposición precisa y resultados limpios..

- Asegúrese de una alineación adecuada: Verifique nuevamente la ubicación del diseño para evitar impresiones desiguales y mantener la coherencia..

- Mantenga limpio el espacio de trabajo: Un entorno de impresión ordenado garantiza que no haya contaminantes que arruinen la calidad de la tela o la tinta..

Conclusión

Eligiendo el La mejor tela para serigrafía. Hace una gran diferencia en la creación de diseños que destacan y duran mucho tiempo.. La tela adecuada ayuda a que tus impresiones luzcan vibrantes y profesionales en todo momento..

A EMDigitalización, Estamos aquí para apoyar sus proyectos creativos con nuestros servicios expertos en arte vectorial.. Prometemos resultados de alta calidad., entrega súper rápida, y una opción de vista previa para que siempre estés satisfecho antes de finalizar.

Si nos estás probando por primera vez, disfruta de un 50% descuento en tu primer pedido! No espere: permítanos ayudarle a hacer realidad sus ideas a precios inmejorables..

preguntas frecuentes

El algodón es el tejido más popular para serigrafía debido a su excelente absorción de tinta y resultados de impresión vibrantes.. Otras opciones como poliéster y mezclas también pueden funcionar bien según el proyecto..

La mejor tela para camisas serigrafiadas suele ser 100% algodón, lo que da diseños nítidos y colores brillantes. Para mayor durabilidad y elasticidad., las mezclas de algodón y poliéster son una excelente opción.

Absolutamente! Telas como la seda, lino, y el nailon se puede utilizar para serigrafía., pero es posible que necesiten tintas especializadas o preparación adicional para lograr resultados de alta calidad..