¿Alguna vez te has preguntado cómo engrasar la máquina de bordar para que siga funcionando sin problemas?? La lubricación regular es imprescindible para mantener el rendimiento de su máquina y garantizar que dure años.. Es una tarea sencilla que evita el desgaste, reduce la fricción, y mantiene tu bordado con un aspecto impecable.

En esta guía, Compartiré un método fácil y paso a paso para engrasar su máquina correctamente.. Si eres nuevo en el bordado o simplemente necesitas un repaso rápido, Estos consejos te ayudarán a cuidar tu máquina sin ningún problema.. Profundicemos y hagamos que su máquina de bordar funcione de la mejor manera!

Cómo engrasar la máquina de bordar | Detailed Process &; Consejos

Suministros esenciales para engrasar su máquina de bordar

Para mantener adecuadamente su máquina, Es crucial saber cómo engrasar la máquina de bordar usando el herramientas para engrasar. Estos elementos esenciales facilitan el proceso y ayudan a garantizar un rendimiento duradero..

- Aceite para máquina de bordar

- cepillo suave

- Auriculares (para una aplicación precisa)

- Paño o pañuelo limpio

- manual de mantenimiento

1. Aceite para máquina de bordar

Usar el aceite adecuado para máquinas de bordar es crucial para un funcionamiento suave y eficiente. This oil is specifically designed to reduce friction and prevent rust on your machine’;s partes móviles. Always opt for the oil recommended by your machine’;s fabricante para evitar posibles daños o problemas de rendimiento.

2. cepillo suave

Un cepillo suave es una herramienta útil para quitar el polvo., hilas, y residuos de los componentes de su máquina. Garantiza una limpieza profunda sin causar rayones ni daños.. Pinceles pequeños o pinceles específicos para máquinas de coser Funciona perfectamente para esta tarea..

3. Auriculares (para una aplicación precisa)

Los auriculares son excelentes para aplicar aceite en zonas de difícil acceso, asegurando precisión y control. Su pequeño tamaño ayuda a prevenir el exceso de aceite y facilita la localización de piezas específicas de la máquina.. Para mejores resultados, Sumerja la punta ligeramente en el aceite para evitar una aplicación excesiva..

4. Paño o pañuelo limpio

A lint-free cloth or tissue is essential for wiping away excess oil and cleaning the machine’;superficies. Los paños de microfibra son ideales ya que no dejan fibras que puedan interferir con el rendimiento de su máquina.. Evite el uso de toallas de papel, que pueden arrojar partículas dentro de la máquina.

5. manual de mantenimiento

El manual de mantenimiento es su guía definitiva para una lubricación adecuada.. Proporciona instrucciones claras sobre dónde aplicar aceite y cuánto usar., tailored specifically to your machine’;modelo. Mantener este manual a mano durante el mantenimiento le ahorrará tiempo y garantizará que no se pierda ningún paso importante..

Áreas clave a lubricar para una máquina de bordar en buen estado

Mantenimiento regular, incluyendo una lubricación adecuada, Es vital para garantizar que su máquina de bordar funcione sin problemas y dure más tiempo.. A continuación se detallan las áreas esenciales que requieren lubricación para mantener su máquina en óptimas condiciones.:

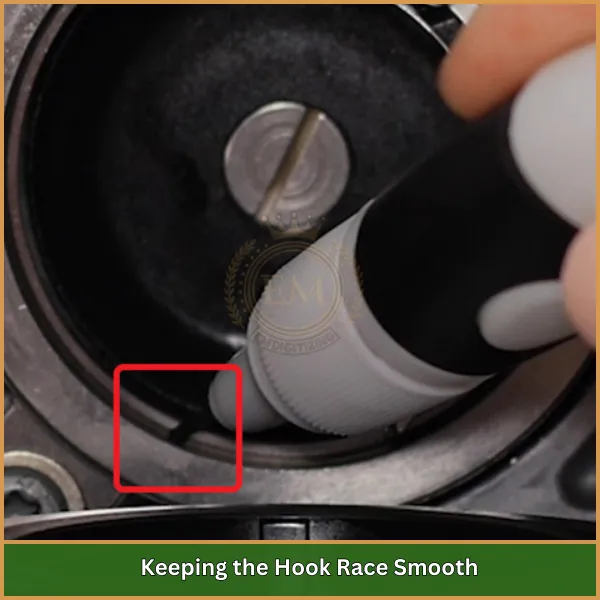

Mantener suave la carrera del gancho

La carrera del gancho es una parte vital de la máquina de bordar donde el gancho se mueve para atrapar el hilo.. Esta área es propensa a la fricción y al desgaste sin la lubricación adecuada.. A small drop of oil before each use and after changing the bobbin can significantly enhance the machine’;rendimiento.

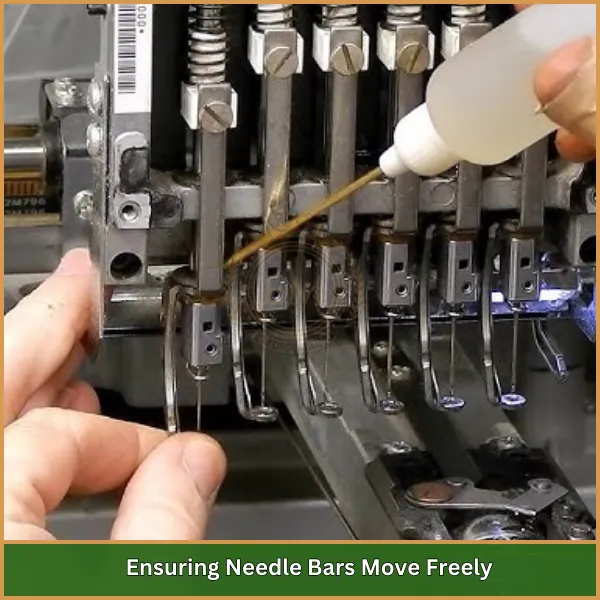

Asegurarse de que las barras de agujas se muevan libremente

Las barras de agujas son responsables del movimiento hacia arriba y hacia abajo de las agujas., que es fundamental para el proceso de costura. Aplicar aceite a la arandela de fieltro ubicada en la barra de agujas inferior cada 40 a 50 horas de uso garantiza un movimiento suave y eficiente, reduciendo el desgaste del mecanismo.

Mantenimiento de la palanca tensora

La palanca tirahilos juega un papel crucial en mover el hilo hacia arriba y hacia abajo durante el bordado.. Sin lubricación, puede volverse menos efectivo o causar puntos desiguales. Una gota de aceite aplicada periódicamente., as suggested in the machine’;manual de instrucciones, ayuda a mantener su funcionalidad.

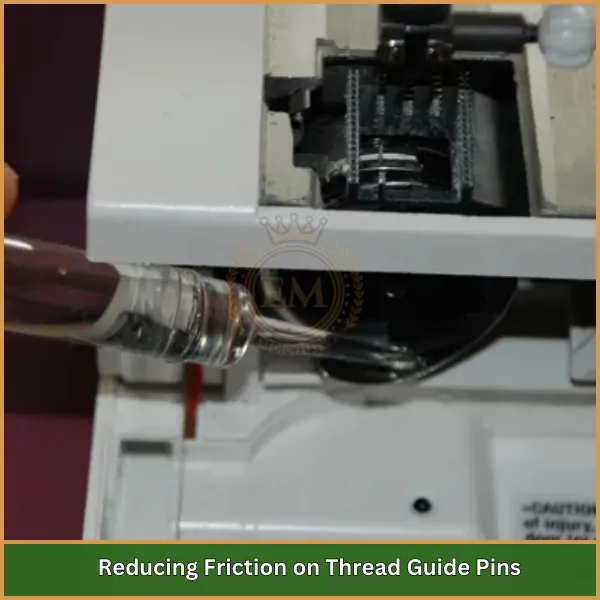

Reducción de la fricción en los pasadores guía del hilo

Los pasadores de la guía del hilo dirigen el hilo suavemente desde el carrete hasta la aguja.. Cuando estos alfileres estén secos, pueden causar resistencia, lo que puede provocar que el hilo se rompa o que las costuras sean desiguales.. Una ligera lubricación garantiza que el hilo se deslice sin esfuerzo y mejora la experiencia general de costura..

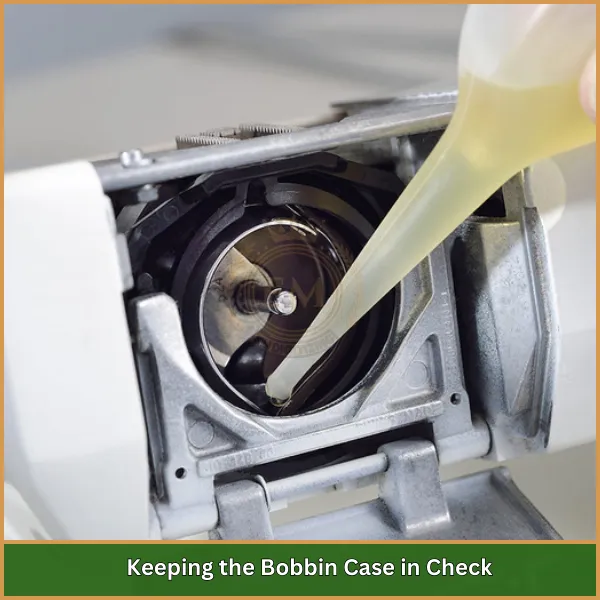

Mantener la caja de la bobina bajo control

La caja de la bobina sujeta la bobina de forma segura y controla la tensión del hilo., que es clave para crear diseños de bordado precisos. Limpiar esta área y aplicar una pequeña cantidad de aceite con regularidad previene problemas de tensión y garantiza una calidad de costura constante..

Cómo engrasar la máquina de bordar

Mantenga su máquina de bordar en óptimas condiciones siguiendo este proceso de engrase paso a paso. El engrase regular garantiza un funcionamiento suave y prolonga la vida útil de la máquina..

1. Prepararse

antes de empezar, Apague y desenchufe su máquina para garantizar la seguridad.. Reúne lo esencial: aceite para máquina de bordar, un cepillo suave, un paño sin pelusa, y otras herramientas necesarias para el trabajo.

2. Acceda a áreas clave

Retire con cuidado piezas como la aguja., placa de garganta, o cualquier otro componente que bloquee el acceso a los puntos de lubricación. Utilice un cepillo suave para limpiar pelusas o residuos., pero evita el aire comprimido, ya que podría empujar la suciedad hacia el interior.

3. Engrase la carrera del gancho

Comience abriendo la tapa del gancho y retirando la caja de la bobina.. Gire ligeramente el volante para colocar la pista del gancho.. Aplicar una sola gota de aceite directamente al anzuelo., teniendo cuidado de no exagerar.

4. Lubrique las barras de agujas

Tire hacia abajo una barra de agujas para bloquearla en su lugar.. Añade una gota de aceite a la arandela de fieltro de la parte inferior de la barra.. Repita este proceso para cada barra de agujas para garantizar un movimiento suave..

5. Abordar otras piezas móviles

Consulte el manual de su máquina para identificar áreas adicionales como pasadores de guía de hilo o mecanismos de tensión que requieren lubricación.. Aplique aceite ligeramente a estas piezas según las instrucciones..

6. terminar

Una vez que todas las áreas necesarias estén engrasadas, use un paño sin pelusa para limpiar el exceso de aceite. Vuelva a montar las piezas retiradas, asegurándose de que todo esté en su lugar de forma segura. Finalmente, Pruebe la máquina con un trozo de tela para confirmar que esté funcionando sin problemas..

7. Establecer una rutina

Para máquinas utilizadas frecuentemente, aceite diariamente o después de cada cambio de bobina. Si utiliza su máquina ocasionalmente, un horario semanal o mensual es suficiente.

Evite estos errores al engrasar su máquina de bordar

Saber engrasar correctamente la máquina de bordar es fundamental para un mantenimiento eficaz. Evite estos errores para mantener su máquina funcionando sin problemas:

- Aplicación de exceso de aceite: Usar demasiado aceite puede provocar una acumulación sucia, teñir telas, y afectando la calidad de la costura.

- Usar aceites inapropiados: Cíñete a aceites específicos para máquinas. Los aceites de uso general o domésticos pueden dañar los mecanismos internos..

- Saltarse la limpieza antes de engrasar: La suciedad y la pelusa que quedan en la máquina pueden mezclarse con el aceite., causando obstrucciones y problemas de rendimiento.

- Pasar por alto los componentes clave: Asegúrese de engrasar todas las piezas esenciales, como la pista del gancho y las barras de agujas, para evitar un desgaste desigual..

- Ignorar la guía del fabricante: No seguir las instrucciones específicas del manual puede resultar en un mantenimiento inadecuado..

- Programa de lubricación inconsistente: El mantenimiento irregular puede secar los componentes, provocando daños innecesarios con el tiempo.

- Saltarse una ejecución de prueba: Pruebe siempre su máquina después de engrasarla para detectar cualquier problema antes de comenzar un proyecto..

- Usar herramientas sucias: Los cepillos o paños sucios pueden introducir contaminantes en la máquina., negando los beneficios de la lubricación.

Siguiendo los pasos correctos y evitando estos errores, se asegurará de que su máquina de bordar permanezca en excelentes condiciones durante muchos años.

Línea de fondo

Cuidar tu máquina de bordar es sencillo, y ahora ya sabes cómo engrasar la máquina de bordar para que siga funcionando como nueva. La lubricación regular no solo mejora el rendimiento sino que también garantiza que su máquina dure muchos años..

Buscando servicios profesionales de digitalización? EMDigitizing lo tiene cubierto! Ofrecemos digitalización de primer nivel a precios inmejorables., tiempos de respuesta súper rápidos, y calidad garantizada. Con nuestra opción de vista previa, Puedes ver tu diseño antes de que esté finalizado para tu total tranquilidad..

Si es la primera vez que haces tu pedido, obtendrás una exclusiva 50% descuento en tu primer diseño! No espere: haga clic a continuación para realizar su pedido hoy y llevar su bordado al siguiente nivel..

preguntas frecuentes

El engrase mantiene su máquina de bordar funcionando sin problemas al reducir el desgaste de las piezas móviles.. También ayuda a mantener una calidad de costura constante y evita daños innecesarios con el tiempo..

El programa de lubricación varía según el uso.. Para uso frecuente, Lo ideal es engrasar diariamente o después de un cambio de bobina.. Si usa su máquina con menos frecuencia, engrasarlo una vez a la semana o al mes debería ser suficiente..

Usar solo máquina de coser de alta calidad aceite diseñado para máquinas de bordar. Evite el uso de aceites domésticos habituales., as they can harm the machine’;s mecanismos internos.