Sublimations-T-Shirt-Druck ist eine fantastische Möglichkeit, hochwertige Qualität zu schaffen, durable prints that won’;T leicht abnutzen. If you’;Interessiert daran, kundenspezifische T-Shirts mit lebendiger Herstellung zu machen, professionelle Designs, Sublimation ist eine großartige Technik zum Erkunden.

Der Prozess ist unkompliziert und ermöglicht es Ihnen, atemberaubende Ergebnisse zu erzielen, die dauern. Whether you’;Ein Anfänger oder Erfahrung haben Erfahrung, Dieser Leitfaden führt Sie durch das Wesentliche des T -Shirt -Sublimation -Drucks, Helfen Sie, die Materialien zu verstehen, Techniken, und Tipps für das bestmögliche Ergebnis.

Sublimations-T-Shirt-Druck: Ein umfassender Leitfaden

Was ist Sublimation Druck??

Es ist ein Prozess, bei dem der Farbstoff in Materialien wie Stoffe übertragen wird, Keramik, oder Metalle. Die im Sublimation Druck verwendete Tinte wird beim Erhitzen in Gas verwandelt, erlauben, die Fasern des Materials durchdringen und lebendig erzeugen, langlebige Drucke.

Diese Methode ist besonders effektiv auf mit Polyester oder Polymer beschichteten Oberflächen, Es entstehen qualitativ hochwertige Bilder, die langlebig und lichtbeständig sind, knacken, oder Peeling. Im Gegensatz zu herkömmlichen Druckmethoden, Durch die Sublimation wird das Design direkt in das Material eingebettet, Dies führt zu einer glatten Oberfläche, die sich wie ein Teil des Stoffes oder Objekts anfühlt.

Vorteile:

- Lebendige Farben: Erzeugt helles Licht, hochwertige Drucke mit satten Farben.

- Haltbarkeit: Designs sind in den Stoff eingebettet, wodurch sie lichtbeständig sind, knacken, oder Peeling.

- Glatte Oberfläche: Keine zusätzlichen Schichten, eine nahtlose geben, glattes Gefühl.

- Umweltfreundlich: Verbraucht im Vergleich zu anderen Druckmethoden weniger Wasser und Energie.

Einschränkungen:

- Stoffbeschränkungen: Funktioniert am besten auf Polyester oder mit Polyester beschichteten Stoffen; nicht ideal für Baumwolle.

- Nur helle Farben: Beschränkt auf weiße oder helle Kleidungsstücke, um eine genaue Farbwiedergabe zu gewährleisten.

- Erstinvestition: Erfordert bestimmte Drucker, Tinten, und Materialien, was zu höheren Anlaufkosten führt.

Benötigte Materialien für den Sublimations-T-Shirt-Druck

Zum Einstieg T-Shirt-Druck Sublimation, Sie benötigen spezielle Materialien und Geräte, die für diesen Prozess entwickelt wurden. Nachfolgend finden Sie die wesentlichen Punkte mit kurzen Beschreibungen und Empfehlungen.

Sublimationsdrucker: Ein Spezialdrucker, der mit Sublimationstinte hochauflösende Bilder für die Übertragung auf Kleidungsstücke erzeugt. Für hochwertige Ergebnisse empfehlen wir Epson SureColor oder Sawgrass.

Sublimationstinte: Diese Tinte verwandelt sich beim Erhitzen in Gas, Dadurch kann es mit Polyestergewebe verschmelzen, sorgt für lebendige und langlebige Drucke. Für langlebige und lebendige Ausdrucke empfehlen wir die Verwendung von Original-Sawgrass- oder Epson-Tinten.

Sublimationspapier: Ein hitzebeständiges Transferpapier, das das gedruckte Design festhält und es beim Pressen mit Hitze auf den Stoff abgibt. Für hochwertige Bildübertragungen empfehlen wir A-SUB- oder TexPrint-Papier.

Heißpressmaschine: Eine Maschine, die hohe Hitze und Druck ausübt, um die Sublimationstinte vom Papier auf den Stoff zu übertragen. Für eine gleichbleibende Leistung empfehlen wir Fancierstudio- oder PowerPress-Wärmepressen.

T-Shirts aus Polyester oder einer Polyestermischung mit hohem Polyesteranteil: Für eine optimale Farbübertragung funktioniert die Sublimation am besten bei Kleidungsstücken aus Polyester oder Stoffen mit hohem Polyesteranteil. Wir empfehlen Jerzees- oder Gildan-T-Shirts mit mindestens 65% Polyesteranteil für beste Ergebnisse.

Hitzebeständiges Klebeband: Wird verwendet, um das Sublimationspapier während des Heißpressvorgangs auf dem T-Shirt zu befestigen, um ein Verrutschen zu verhindern. Wir empfehlen hitzebeständiges Klebeband von Cricut, um das Papier sicher an Ort und Stelle zu halten.

Schutzpapier oder Teflonfolie: Wird zwischen der Heißpresse und dem Sublimationspapier platziert, um sowohl das T-Shirt als auch die Heißpresse vor dem Auslaufen von Tinte zu schützen. Für den Langzeitgebrauch empfehlen wir wiederverwendbare Teflonplatten.

Design-Software (Optional): Mit Programmen wie Adobe Illustrator oder CorelDRAW können Sie erstellen individuelle Designs und achten Sie auf die richtige Größe für den Sublimationsdruck. Für die Designerstellung empfehlen wir Adobe Illustrator für Profis und Canva für Einsteiger.

Schritt-für-Schritt-Anleitung für den Sublimations-T-Shirt-Druck

Hier finden Sie eine umfassende Anleitung zum T-Shirt-Druck, in klare Schritte gegliedert:

1. Bereiten Sie Ihr Design vor

Beginnen Sie mit der Erstellung oder Auswahl Ihres Designs mithilfe einer Designsoftware wie Adobe Illustrator, Coreldraw, oder Canva. Stellen Sie sicher, dass das Design die richtige Größe für das T-Shirt hat und über eine hohe Auflösung verfügt, um gestochen scharfe Ergebnisse zu erzielen. Wenn das Design Text oder Bilder enthält, die in eine bestimmte Richtung ausgerichtet sein müssen, Vergessen Sie nicht, das Bild vor dem Drucken zu spiegeln, damit es korrekt auf den Stoff übertragen wird.

Wenn Ihr Bild nicht klar ist oder eine niedrige Auflösung aufweist, Mach dir keine Sorgen! EMDigitalisieren kann es für Sie in ein hochwertiges Vektorbild umwandeln. Wir bieten diesen Service zu erschwinglichen Preisen an, Stellen Sie sicher, dass Ihr Design scharf aussieht und für den Sublimationsdruck bereit ist.

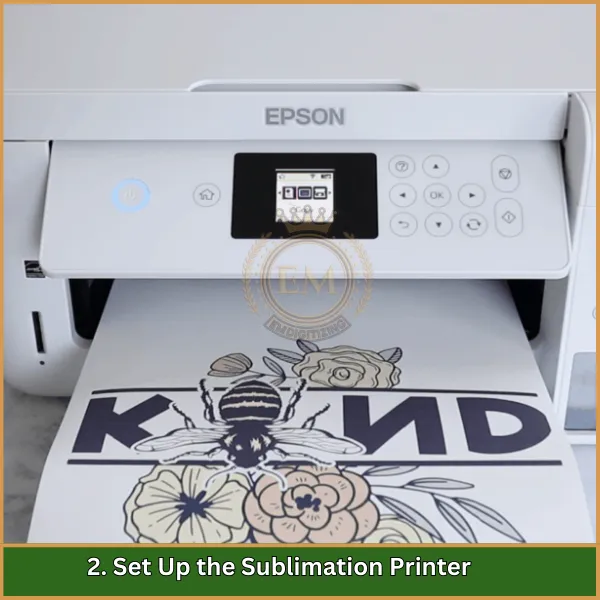

2. Richten Sie den Sublimationsdrucker ein

Beladen Sie Ihren Sublimationsdrucker mit Sublimationstinte und Sublimationspapier. Stellen Sie sicher, dass in den Druckereinstellungen alles richtig ausgerichtet ist, und drucken Sie Ihr gespiegeltes Design auf das Sublimationspapier. Für lebendige Farben und eine qualitativ hochwertige Übertragung ist die Verwendung des richtigen Papiers und der richtigen Tinte unerlässlich.

3. Bereiten Sie das T-Shirt vor

Wählen Sie ein T-Shirt aus Polyester oder einer Mischung mit hohem Polyesteranteil, Da die Sublimation auf diesen Stoffen am besten funktioniert. Mindestens 65% Polyester wird empfohlen. Heizen Sie Ihre Wärmepresse auf die empfohlene Temperatur vor, Typischerweise um 375-400 ° F., und legen Sie Ihr T-Shirt flach auf die Presse. Stellen Sie sicher, dass es keine Falten gibt, Feuchtigkeit, oder FINT auf dem Stoff, da diese die Qualität der Übertragung beeinflussen können.

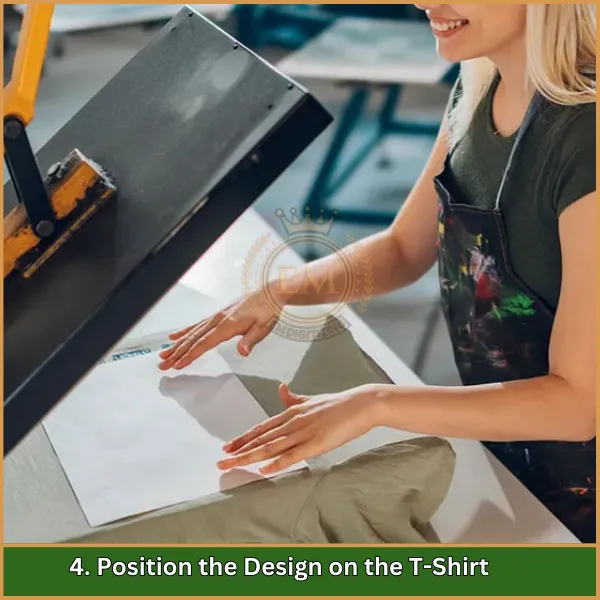

4. Positionieren Sie das Design auf dem T-Shirt

Sobald das T-Shirt fertig ist, Legen Sie Ihr gedrucktes Design mit dem Favorin auf den Bereich, in dem Sie es übertragen möchten. Verwenden Sie hitzebeständiges Band, um das Sublimationspapier am T-Shirt zu sichern, Stellen Sie sicher, dass es sich während des Pressungsprozesses nicht bewegt. Die richtige Ausrichtung ist der Schlüssel, um Ihr Design an der richtigen Stelle auf dem T-Shirt zu bringen.

5. Wärme und Druck auftragen

Legen Sie ein schützendes Teflonblatt oder Pergamentpapier über das Sublimationspapier und das T-Shirt. Schließen Sie die Wärmepresse, Sicherstellen, dass der richtige Druck ausgeübt wird. Drücken Sie das T-Shirt für 30-60 Sekunden, abhängig vom Stoff und den Presseinstellungen. Achten Sie auf die richtige Temperatur, Zeit, und Druck, um eine Unter- oder Überübertragung des Designs zu vermeiden.

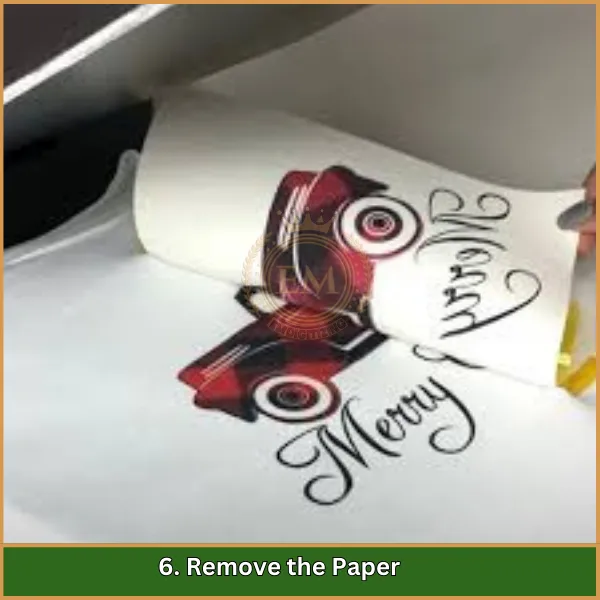

6. Entfernen Sie das Papier

Nach Ablauf der Presszeit, Öffnen Sie vorsichtig die Heißpresse und ziehen Sie das Sublimationspapier ab, solange es noch warm ist. Das Design sollte nun vollständig auf das T-Shirt übertragen sein, mit lebendigen Farben und einer glatten Oberfläche, die in den Stoff eingestickt ist.

7. Lassen Sie das T-Shirt abkühlen

Lassen Sie das T-Shirt vollständig abkühlen, bevor Sie es anfassen, um ein Verschmieren oder Verzerren des Aufdrucks zu vermeiden. Durch die Kühlung können sich die Tinten vollständig im Stoff festsetzen, Gewährleistung eines langlebigen und langlebigen Designs.

8. Überprüfen Sie das Design

Sobald es abgekühlt ist, Untersuchen Sie das T-Shirt, um sicherzustellen, dass das Design korrekt übertragen wurde. Überprüfen Sie, ob Farbunstimmigkeiten oder unvollständige Übertragungen vorliegen. Wenn benötigt, Nehmen Sie für zukünftige Drucke Anpassungen an den Einstellungen Ihrer Transferpresse vor, um die Qualität zu verbessern.

Tipps für hochwertige Sublimationsdrucke

Um sicherzustellen, dass Ihre Sublimations-T-Shirt-Drucke lebendig sind, dauerhaft, und professionell aussehend, Beachten Sie die folgenden Tipps:

- Verwenden Sie hochauflösende Designs: Stellen Sie sicher, dass Ihr Design mindestens hat 300 DPI für klare und gestochen scharfe Ausdrucke.

- Wählen Sie den richtigen Stoff: Verwenden Sie für eine optimale Farbübertragung Polyester- oder Polyestermischgewebe.

- Wärmen Sie das T-Shirt vor: Wärmen Sie den Stoff vor dem Bügeln einige Sekunden lang vor, um Feuchtigkeit und Falten zu entfernen.

- Stellen Sie die richtige Temperatur und den richtigen Druck ein: Befolgen Sie die empfohlenen Temperatureinstellungen, Druck, und Zeit basierend auf Ihrem Stoff und Ihrer Maschine.

- Verwenden Sie hitzebeständiges Klebeband: Befestigen Sie das Sublimationspapier mit hitzebeständigem Klebeband, um ein Verrutschen während des Druckvorgangs zu verhindern.

- Schützen Sie die Transferpresse: Verwenden Sie immer eine Teflonfolie oder Pergamentpapier, um die Druckmaschine vor dem Auslaufen von Tinte zu schützen.

- Papier im warmen Zustand abziehen: Für eine sauberere Übertragung entfernen Sie das Sublimationspapier, solange es noch warm ist.

- Überprüfen Sie regelmäßig den Tintenstand: Achten Sie auf den richtigen Tintenstand, um verblasste Drucke zu vermeiden und lebendige Farben zu gewährleisten.

Indem Sie diese Tipps befolgen, Sie können hochwertige Sublimationsdrucke erzielen, die hervorstechen und lange halten.

So pflegen Sie T-Shirts mit Sublimationsdruck?

Um die Lebendigkeit und Langlebigkeit von T-Shirts mit Sublimationsdruck zu erhalten, ist die richtige Pflege unerlässlich. Befolgen Sie diese einfachen Tipps, damit Ihre Drucke immer frisch aussehen:

- In kaltem Wasser waschen: Verwenden Sie kaltes Wasser, um ein Ausbleichen zu verhindern und die Helligkeit des Designs zu erhalten.

- Drehen Sie das Innere nach Außen: Drehen Sie das T-Shirt vor dem Waschen um, um den Aufdruck vor Reibung zu schützen.

- Verwenden Sie ein mildes Reinigungsmittel: Vermeiden Sie aggressive Chemikalien oder Bleichmittel, die den Druck beschädigen können.

- Vermeiden Sie Weichspüler: Weichspüler können den Druck mit der Zeit schwächen.

- An der Luft oder bei schwacher Hitze trocknen: Lufttrocknung wird bevorzugt, aber wenn Sie einen Trockner benutzen, Stellen Sie es auf niedrige Hitze, um Schäden am Druck zu vermeiden.

- Vermeiden Sie es, den Druck zu bügeln: Falls Bügeln notwendig ist, Vermeiden Sie direkte Hitzeeinwirkung auf das gedruckte Design; Auf der Rückseite bügeln oder ein Schutztuch verwenden.

Indem Sie diese Pflegehinweise befolgen, Sie können die Lebensdauer Ihrer T-Shirts mit Sublimationsdruck verlängern und sie länger wie neu aussehen lassen.

Fazit

Der Farbsublimationsdruck von T-Shirts ist eine einfache und effektive Möglichkeit, langlebige T-Shirts zu erstellen, lebendige Designs. Whether you’;Wir stellen T-Shirts für den persönlichen Gebrauch oder für Ihr Unternehmen her, Diese Technik stellt sicher, dass Ihre Drucke großartig aussehen und lange halten. Mit den richtigen Schritten, Jeder kann professionelle Ergebnisse erzielen.

Brauchen benutzerdefinierte Vektordesigns für Ihre Projekte? EMDigitizing ist für Sie da! Wir sind auf die Bereitstellung hochwertiger Vektorisierungsdienste mit schneller Abwicklung und erschwinglichen Preisen spezialisiert. Und für Erstkunden, Wir bieten ein Erstaunliches 50% Rabatt.

Lassen Sie uns dabei helfen, Ihre Designideen zum Leben zu erwecken!

Häufig gestellte Fragen

Als bester Drucker für T-Shirts gilt oft der Sawgrass Virtuoso SG500, bekannt für seine hochwertigen Drucke, Zuverlässigkeit, und Kompatibilität mit verschiedenen Transferpapieren.

Um einen Drucker zu verwenden, Erste, Drucken Sie Ihr Design mit dem Drucker auf Sublimationspapier, Verwenden Sie dann eine Heißpresse, um die Tinte unter hoher Temperatur und hohem Druck vom Papier auf ein Hemd auf Polyesterbasis zu übertragen.

Der Sublimationsdruck auf T-Shirts hält in der Regel ein Leben lang, da sich der Farbstoff chemisch mit dem Stoff verbindet und beständig gegen Ausbleichen durch Waschen oder Sonnenlicht ist.