Farbstoffmigration im Siebdruck kann ein frustrierendes Problem sein, Besonders beim Drucken auf synthetischen Stoffen wie Polyester. Es tritt auf, wenn der Farbstoff des Stoffes in die gedruckte Tinte blüht, verursacht, dass die Farben in Ihrem Design verschieben oder verblassen. Dieser Effekt zeigt sich oft nach dem Härtungsvorgang, Während die Wärme den Stofffarbstoff aktiviert, führt zu unerwünschter Farbmischung.

Aber keine Sorge - es gibt effektive Möglichkeiten, dies anzugehen! Verwenden von tiefen Tinten, Auftragen einer Farbstoffblockierungsschicht, Das Einstellen von Härtungstemperaturen sind nur einige Methoden, mit denen Sie Ihre Drucke knusprig und farblich halten können. Mit diesen Techniken, Sie können es verhindern und sicherstellen, dass Ihre Designs so lebendig bleiben wie beabsichtigt.

Farbstoffmigration im Druck: Was es ist und wie man es kontrolliert?

Was ist Farbstoffmigration im Druck??

It refers to the process where dye from the fabric or garment material transfers or “;bleeds”; in die Tintenschicht eines gedruckten Designs. Dieses Problem tritt häufig in synthetischen Stoffen auf, vor allem Polyester, Wenn er während des Aushärtungsprozesses Wärme ausgesetzt ist. Die Farbstoffmoleküle werden mobil und können sich in die Tinte bewegen, Verfärbung oder Farbton verursachen, Was die beabsichtigten Farben des Drucks verändert und die Gesamtdruckqualität reduziert.

Was sind die Faktoren, die Farbstoffmigration verursachen?

Dies geschieht aufgrund mehrerer Faktoren, die beeinflussen, wie sich die Farben im Stoff bewegen. Wenn Sie diese verstehen, können Sie unerwünschte Farbänderungen in Ihren Drucken verhindern.

- Stofftypen anfällig

- Wärme- und Heilungstemperatur

- Farbstoffqualität und Stabilität

- Tintenart und Komposition

- Luftfeuchtigkeit während des Drucks

- Zeit und Druck angewendet

1. Stofftypen anfällig

Bestimmte Stoffe sind anfälliger für die Migration im Druck als andere. Synthetische Materialien, wie Polyester und Nylon, sind besonders anfällig, weil sie häufig hitzempfindliche Farbstoffe enthalten. Wenn während des Druckprozesses Wärme angewendet wird, Diese Farbstoffe können in die Tintenschicht bluten, Verfärbung verursachen. Blended Fabrics mit einem hohen Prozentsatz synthetischer Fasern können diese Probleme auch auftreten.

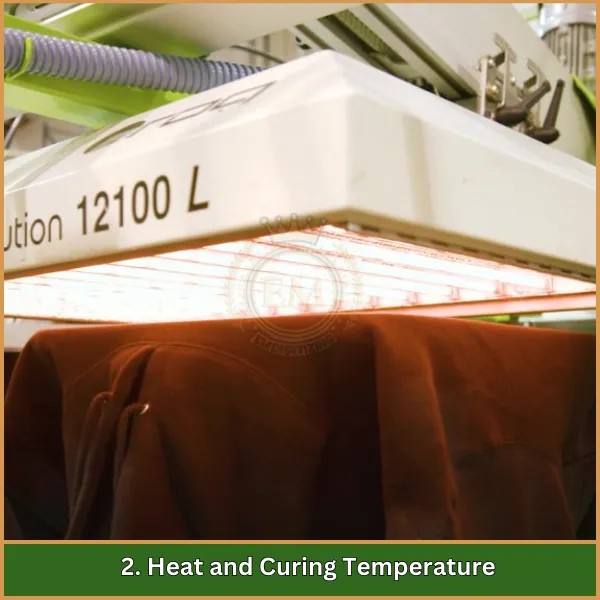

2. Wärme- und Heilungstemperatur

Die im Härtungsprozess verwendete Wärmemenge ist ein wesentlicher Faktor bei der Farbmigration. Wenn die Temperatur zu hoch ist, Es aktiviert den Farbstoff in synthetischen Stoffen, Erlauben, in die Tinte zu wandern. Um es zu minimieren, Es wird empfohlen, nach Möglichkeit niedrigere Aushärttemperaturen zu verwenden, oder spezialisierte Tinten mit niedrigem Cure, die den Bedarf an hoher Hitze verringern.

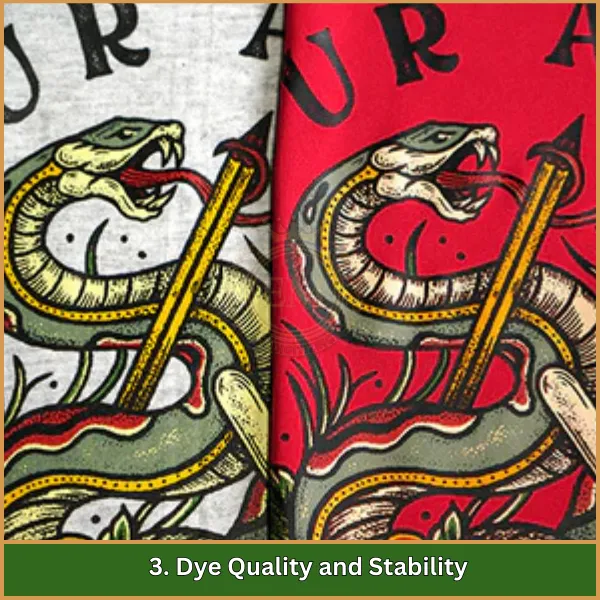

3. Farbstoffqualität und Stabilität

Die Stabilität des im Stoff verwendeten Farbstoffs spielt eine wichtige Rolle in diesem Thema. Es ist wahrscheinlicher, dass niedrige oder instabile Farbstoffe bei Wärme und Druck ausgesetzt sind. Stoffe mit hoher Qualität gefärbt, Stallfarbstoffe sind weniger anfällig für Migration, Stellen Sie sicher, dass die gedruckten Farben wahr bleiben.

4. Tintenart und Komposition

Die Art der verwendeten Tinte kann auch die Farbmigration beeinflussen. Bestimmte Tinten werden so formuliert, dass sie der Migration blockieren oder widerstehen, sie für geeignet machen für Drucken auf synthetischen Stoffen. Beispiele sind:

- Plastisol -Tinten niedriger Blutungen: Diese Tinten sind speziell entwickelt, um die Migration zu reduzieren, indem eine Barriereschicht zwischen dem Stoff und der Tinte gebildet wird.

- Polyesterfreundliche Tinten: Diese Tinten werden dazu gebracht, bei niedrigeren Temperaturen zu heilen, Reduzierung des Migrationsrisikos auf Polyester- und synthetischen Mischungen.

- Unterbasis-Tinten mit Farbstoffblockieren: Diese Tinten wirken als Primerschicht, Verhindern, dass Farbstoff in die oberen Tintenschichten sickert.

5. Luftfeuchtigkeit während des Drucks

Luftfeuchtigkeit in der Druckumgebung kann zur Farbmigration beitragen. Eine hohe Luftfeuchtigkeit kann den Feuchtigkeitsgehalt in Stofffasern erhöhen, Sie sind anfälliger für hitzebedingte Druckmigration während des Heilung. Es ist wichtig, die Luftfeuchtigkeit im Druckbereich zu kontrollieren, um eine übermäßige Farbstoffbewegung zu verhindern.

6. Zeit und Druck angewendet

Die Zeit und den Druck, der während des Druck- und Aushärtungsprozesses ausgeübt wird. Übermäßiger Druck oder längere Wärmeexposition kann dazu führen, dass der Farbstoff leichter in die Tinte übergeht. Wenn Sie gerade genug Druck verwenden und die Expositionszeit während der Heilung verkürzen, können Sie die Migration verhindern, Besonders auf empfindlichen Stoffen.

So verhindern Sie die Farbstoffmigration im Screen -Druck?

Es ist wichtig, die Qualität von aufrechtzuerhalten gedruckte Designs auf synthetischen Stoffen. Im Folgenden finden Sie effektive Methoden zur Kontrolle und der Behebung von Farbstoffmigrationsproblemen im Screen -Druck.

- Verwenden Sie Tinten mit niedrigen Blutungen

- Niedrigere Aushärttemperatur

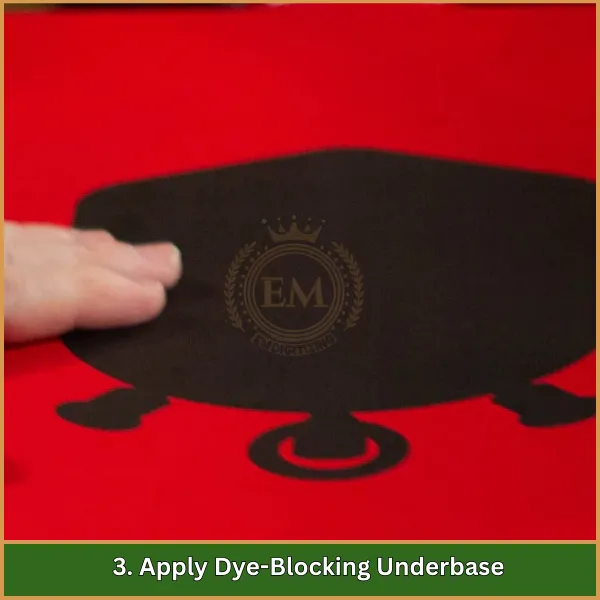

- Dye-Blocking-Unterbasis auftragen

- Wählen Sie Farbstabilitätsstoffe

- Feuchtigkeitswerte kontrollieren

- Verwenden Sie die richtigen Druck- und Zeiteinstellungen

- Testdrucke

1. Verwenden Sie Tinten mit niedrigen Blutungen

Sie sind speziell formuliert, um der Farbmigration zu widerstehen, indem sie eine Barriere zwischen dem Stofffarbstoff und der gedruckten Tinte erzeugen. Diese Tinten wirken als Farbstoffmigrationsblocker, Ideal zum Drucken auf synthetischen Stoffen, Wie Polyester, wo Migration wahrscheinlicher ist. Die Verwendung von Tinten mit niedrigem Blocken hilft dabei, die wahren Farben des Drucks beizubehalten und verhindert unerwünscht.

2. Niedrigere Aushärttemperatur

Hohe Aushärttemperaturen können Migration in synthetischen Stoffen auslösen. Die Senkung der Härtemperatur verringert die Wahrscheinlichkeit, dass sich der Farbstoff in die Tintenschicht bewegt. Viele Tinten mit niedrigem Cure sind so konzipiert, dass sie bei niedrigeren Temperaturen effektiv heilen, Machen Sie sie zu einer großartigen Option, um die Migration im Siebdruck zu reduzieren.

3. Dye-Blocking-Unterbasis auftragen

Eine unterblockende Unterbasis fungiert als Primerschicht, die verhindert, dass Farbstoff in die gedruckte Tinte sickert. Diese Unterbasis, Typischerweise weiß oder klar, wird vor der Haupttintenschicht angewendet, um eine Schutzbarriere zu erzeugen. Es ist besonders nützlich, um eine Migration in dunklen oder farbenfrohen synthetischen Stoffen zu verhindern.

4. Wählen Sie Farbstabilitätsstoffe

Einige Stoffe sind stabil gefärbt, hochwertige Farbstoffe, die weniger anfällig für Migration sind. Die Entscheidung für farbstabilische Stoffe kann dazu beitragen, das Risiko einer Migration zu verringern und das gedruckte Design intakt zu halten. Überprüfen Sie die Stoffspezifikationen oder konsultieren Sie Lieferanten, um sicherzustellen, dass die verwendeten Materialien für den Siebdruck geeignet sind.

5. Feuchtigkeitswerte kontrollieren

Eine hohe Luftfeuchtigkeit in der Druckumgebung kann die Wahrscheinlichkeit einer Migration erhöhen. Überschüssige Feuchtigkeit macht die Stofffasern empfindlicher gegenüber Wärme, was dazu führen kann, dass der Farbstoff blutet. Durch die Aufrechterhaltung der optimalen Luftfeuchtigkeitsniveaus im Arbeitsbereich können Sie die Farbstoffbewegung kontrollieren und konsistentere Druckergebnisse erzeugen.

6. Verwenden Sie die richtigen Druck- und Zeiteinstellungen

Übermäßiger Druck oder längere Wärmeexposition während des Heilens kann die Farbmigration fördern. Durch die Verwendung der richtigen Druckmenge und die Verkürzung der Härtungszeit, soweit möglich, Sie können die Farbstoffübertragung in die Tinte minimieren. Wenn Sie diese Einstellungen basierend auf dem Stofftyp einstellen, können Sie die Migration verhindern und die Qualität des endgültigen Drucks verbessern.

7. Testdrucke

Bevor Sie mit großen Druckläufen fortfahren, Testen Sie eine kleine Probe, um nach Anzeichen einer Migration zu überprüfen. Mit diesem Schritt können Sie die erforderlichen Anpassungen vornehmen, wie das Ändern der Härtungszeit oder das Umschalten auf eine Tinte mit niedrigem Blut, Um sicherzustellen, dass die endgültigen Drucke lebendig und frei von Migration sind.

Tipps zur Verhinderung der Farbstoffmigration in Ihren Drucken

Die Vermeidung von Farbmigration ist für die Erzeugung von Knusprigen unerlässlich, Drucken ohne unerwartete Farbverschiebungen reinigen. Hier sind einige einfache Schritte, um Ihre Designs scharf aussehen zu lassen:

- Entscheiden Sie sich für Stoffe, die mit stabilen Färben gefärbt sind, hochwertige Farben, da es weniger wahrscheinlich blutet, dass diese bluten.

- Wählen Sie niedrig gestrichen.

- Verwenden Sie eine farbstblockierende Primerschicht für Stoffe, die für den zusätzlichen Schutz für Migration anfällig sind.

- Setzen Sie niedrigere Aushärttemperaturen, um das Risiko von Farbstoffblutungen von Wärme zu verringern.

- Halten Sie die Luftfeuchtigkeitsniveaus in Schach, um zu verhindern, dass Feuchtigkeit die Farbstoffbewegung beeinflusst.

- Wenden Sie den richtigen Druck aus und vermeiden Sie eine Überhüllung, um die Migration zu begrenzen.

- Testen Sie immer einen Beispieldruck, um sicherzustellen, dass Ihre Endergebnisse der Farbe treu bleiben.

Zusammenfassung

Zum Abschluss, Die Farbstoffmigration in Schach zu halten, ist für lebendige Wesentliche von wesentlicher Bedeutung, langlebige Drucke. Mit den richtigen Techniken-wie bei der Auswahl von Tinten mit niedrigen Bemerzen, Härtungstemperaturen einstellen, und Anwenden von Farbstoffblockierschichten-Sie können sicher unerwünschte Farbverschiebungen in Ihren Designs vermeiden.

Für diejenigen, die erstklassige Vektor-Kunstdienste suchen,, EMDigitizing ist hier, um zu helfen! Wir bieten qualitativ hochwertige Vektorkunst mit schnellen Turnaround-Zeiten und erschwinglichen Preisen. Plus, Wir garantieren Qualität und bieten eine Vorschau -Option, Sie sind sich also immer sicher über Ihr endgültiges Design. Wenn Sie zum ersten Mal Kunde sind, nutzen von a 50% Rabatt auf Ihre erste Bestellung! Bereit, Ihre Designs zum Leben zu erwecken? Beginnen Sie mit EMDigitalisierung Heute!