Der Sonderfarben-Siebdruck gilt als eine der zuverlässigsten Methoden, um gestochen scharfe und lebendige Designs zu erzielen. Perfekt für Branding- und Werbematerialien, Es ist bekannt für seine Präzision und die Fähigkeit, Farben hervorzuheben. Ob Sie an Bekleidung arbeiten, Beschilderung, oder individuelle Drucke, Diese Methode liefert jedes Mal konsistente Ergebnisse.

Neugierig, wie es funktioniert oder warum es so beliebt ist? In diesem Ratgeber, Wir gehen auf die Details ein, Entdecken Sie seine einzigartigen Vorteile, und vergleichen Sie es mit anderen Druckmethoden, um zu entscheiden, ob es die richtige Wahl für Ihr Projekt ist.

Umfassender Leitfaden zum Sonderfarben-Siebdruck

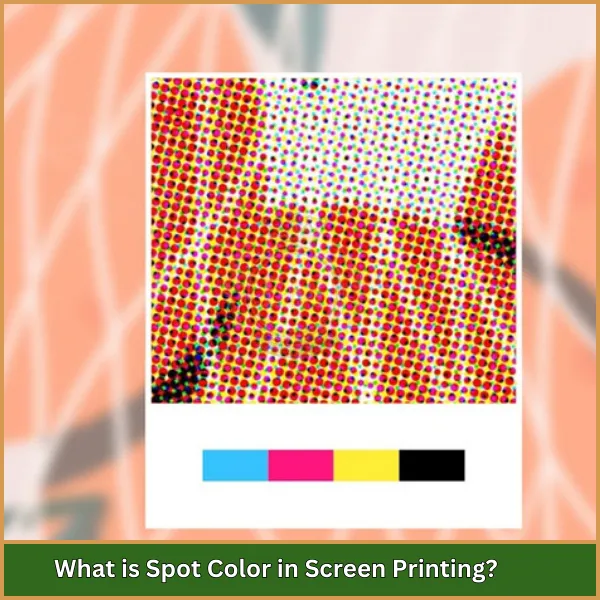

Was ist Sonderfarbe im Siebdruck??

Es bezieht sich auf eine bestimmte Methode, Vorgemischte Tintenfarben werden direkt auf den Druck aufgetragen, ohne zu verblenden oder zu schattieren. Jede Farbe wird in ihrer reinen Form durch separate Siebe gedruckt, scharf erstellen, lebendig, und konsistente Designs, Wird normalerweise für Logos verwendet, Text, oder einfache Grafiken.

Vorteile des Sonderfarbdrucks

- Erzeugt Lebendigkeit, Gleichbleibende Farben mit vorgemischten Tinten.

- Kostengünstig für einfache Designs mit weniger Farben.

- Hochdeckende Tinten sorgen für eine hervorragende Deckkraft, auch auf dunklen Oberflächen.

- Ermöglicht eine präzise Farbanpassung, Unverzichtbar für Logos und Branding.

- Ideal für den Massendruck, Aufrechterhaltung der Einheitlichkeit über große Mengen hinweg.

- Einfacherer Einrichtungsprozess im Vergleich zu komplexen Druckmethoden.

Einschränkungen beim Sonderfarbdruck

- Beschränkt auf Volltonfarben; Nicht geeignet für Farbverläufe oder fotorealistische Designs.

- Höhere Kosten und Rüstzeit für mehrfarbige oder detaillierte Designs.

- Zeitaufwändig bei kleinen oder einzelnen Druckaufträgen.

- Erfordert eine präzise Bildschirmausrichtung, um eine Fehlausrichtung zu vermeiden.

- Feine Details sind in Volltonfarben möglicherweise nicht so scharf oder klar.

- Herkömmliche Tinten können ohne ordnungsgemäße Entsorgung eine größere Umweltbelastung haben.

Wie sich der Spot-Farbdruck von anderen Drucken unterscheidet

Beim Vergleich von CMYK und Spot Farbsiebdruck, Der Hauptunterschied liegt in der Art und Weise, wie Farben erzeugt und angewendet werden. Beim Sonderfarbdruck werden vorgemischte Farben verwendet, Festtinten für präzise und lebendige Farben, Damit eignet es sich ideal für Designs, die eine exakte Farbabstimmung erfordern, wie Logos und Branding. Jede Farbe wird einzeln aufgetragen, Gewährleistung von Konsistenz und Klarheit, insbesondere für einfache Designs mit begrenzten Farben.

Im Gegensatz, Beim CMYK-Druck werden vier Grundfarben gemischt: Cyan, Magenta, gelb, und Schwarz – um ein breites Farbspektrum zu erzeugen. Während CMYK für fotorealistische Bilder und Farbverläufe vielseitiger ist, Manchmal gelingt es nicht, einheitliche und lebendige Töne für bestimmte Farben zu erzielen. Sonderfarbendruck, deshalb, sticht in Szenarien heraus, in denen Farbgenauigkeit und Lebendigkeit nicht verhandelbar sind.

Benötigte Materialien und Werkzeuge für den Sonderfarben-Siebdruck

Zur Erzielung hochwertiger Ergebnisse beim Siebdruck von Sonderfarben, Es ist wichtig, über die richtigen Materialien und Werkzeuge zu verfügen, um präzise und lebendige Drucke zu gewährleisten.

Materialien

- Bildschirme: Vorgestreckte oder vorbeschichtete Siebe mit der passenden Maschenzahl für Ihr Design.

- Sonderfarbentinten: Vorgemischte Plastisol- oder wasserbasierte Tinten für den Volltonauftrag.

- Emulsion: Lichtempfindliche Beschichtung auf Sieben zur Herstellung von Schablonen.

- Schablonenfolie (Optional): Alternative zur Emulsion für einfachere Designs.

- Substrat: Elemente zum Drucken, wie T-Shirts, Papier, oder andere Materialien.

- Rakel: Wird verwendet, um Tinte durch das Sieb auf das Substrat zu drücken.

- Reinigungschemikalien: Entfetter, Emulsionsentferner, und Tintenreiniger zur Wartung von Bildschirmen.

Werkzeuge

- Siebdruckpresse: Eine manuelle oder automatische Presse zum Halten der Bildschirme und zur Gewährleistung einer präzisen Registrierung.

- Belichtungseinheit: Ausrüstung zum Härten von Emulsionen auf Bildschirmen mittels UV-Licht.

- Flash-Trockner: Wird zum Aushärten von Tinte zwischen Schichten oder zum teilweisen Trocknen unter Basisdrucken verwendet.

- Heißpresse oder Durchlauftrockner: Zur vollständigen Aushärtung von Tinten und Gewährleistung der Haltbarkeit.

- Registrierungsleitfäden: Werkzeuge zum genauen Ausrichten von Bildschirmen für mehrfarbige Drucke.

- Design-Software: Programme wie Adobe Illustrator oder CorelDRAW zum Erstellen von Sonderfarbseparationen.

Was ist der Prozess des Sonderfarbdrucks??

Das Sonderfarbenverfahren im Siebdruck erfordert die sorgfältige Befolgung der Schritte, um eine lebendige Wirkung zu gewährleisten, scharf, und präzise Drucke mit Vollton, vorgemischte Tinten. Diese Methode ist Ideal für Designs mit definierten Farben, wie Logos oder Text.

Schritt 1: Vorbereiten des Designs

Der Prozess beginnt mit der Erstellung eines Designs, das auf den Sonderfarbendruck zugeschnitten ist.

- Verwenden Sie Designsoftware wie Adobe Illustrator oder CorelDRAW, um die Grafik in verschiedene Sonderfarben zu unterteilen.

- Stellen Sie sicher, dass jede Farbe beschriftet und als separate Ebene oder Datei vorbereitet ist.

- Sonderfarbendesigns sollten keine Farbverläufe oder Schattierungen enthalten, sondern sich auf einfarbige Farbblöcke konzentrieren.

Schritt 2: Erstellen der Bildschirmschablone

Eine Schablone, oder Bildschirm, ist darauf vorbereitet, jede Sonderfarbe auf das Substrat zu übertragen.

- Tragen Sie mit einem Spachtelgerät eine Schicht lichtempfindlicher Emulsion gleichmäßig auf den Bildschirm auf.

- Platzieren Sie das Design (gedruckt auf einer transparenten Folie) auf den Bildschirm und setzen Sie ihn UV-Licht aus.

- Das Licht verhärtet die Emulsion, außer wo das Design es blockiert, Verlassen des Schablonenbereichs.

- Spülen Sie den Bildschirm mit Wasser ab, um die unbelichtete Emulsion abzuwaschen, das Design enthüllen.

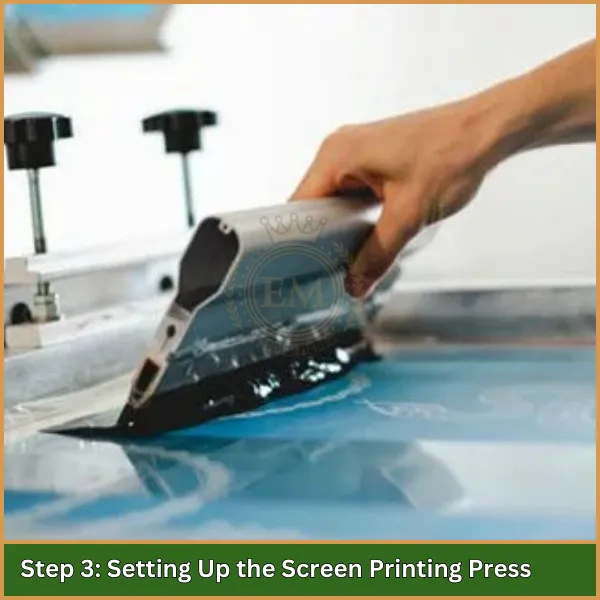

Schritt 3: Einrichten der Siebdruckmaschine

Die richtige Ausrichtung ist für den mehrfarbigen Spotdruck von entscheidender Bedeutung.

- Befestigen Sie das Sieb an der Siebdruckmaschine.

- Verwenden Sie Ausrichtungshilfen oder Markierungen, um sicherzustellen, dass jedes Sieb für mehrfarbige Drucke perfekt ausgerichtet ist.

- Überprüfen Sie die Ausrichtung anhand von Testdrucken, bevor Sie mit dem vollständigen Stapel fortfahren.

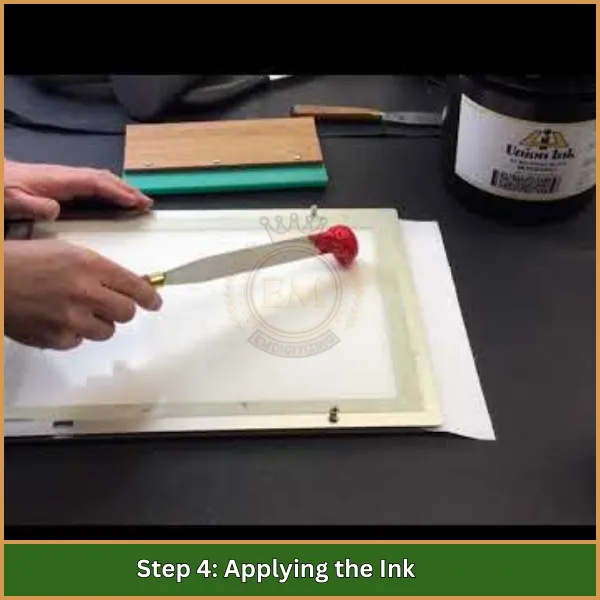

Schritt 4: Auftragen der Tinte

Dies ist die Druckphase, wobei jede Sonderfarbe auf das Substrat übertragen wird.

- Tragen Sie die ausgewählte Sonderfarbentinte auf den Bildschirm auf.

- Drücken Sie die Tinte mit einem Rakel in einer gleichmäßigen Bewegung durch die Schablone auf den Untergrund.

- Wiederholen Sie den Vorgang für jede Farbe, Reinigen oder Ersetzen der Siebe zwischen den Farben, falls erforderlich.

Schritt 5: Aushärten der Tinte

Durch die Aushärtung wird sichergestellt, dass die Tinte dauerhaft auf dem Untergrund haftet.

- Verwenden Sie einen Flash-Trockner zum teilweisen Aushärten zwischen den Tintenschichten in mehrfarbigen Designs.

- Härten Sie das endgültige Design mit einer Heißpresse oder einem Fließbandtrockner vollständig aus, typischerweise bei 320°F (160°C) für Plastisolfarben.

Schritt 6: Reinigen und Wiederverwenden von Bildschirmen

Nach dem Drucken, Siebe sollten gereinigt und für den späteren Gebrauch ordnungsgemäß aufbewahrt werden.

- Entfernen Sie überschüssige Tinte mit einem Bildschirmreiniger.

- Tragen Sie einen Emulsionsentferner auf, um die Schablone aufzulösen und das Sieb wiederherzustellen.

- Gründlich ausspülen und die Siebe in einer sauberen Umgebung trocknen lassen.

Anwendungen des Sonderfarbdrucks

Es handelt sich um eine vielseitige Technik, die für ihre Fähigkeit bekannt ist, präzise und lebendige Farbausgaben zu liefern. Es wird in verschiedenen Bereichen häufig eingesetzt, um professionelle und auffällige Ergebnisse zu erzielen. Hier glänzt es:

- Professionelle Visitenkarten: Der Sonderfarbdruck sorgt dafür, dass markenspezifische Farbtöne perfekt aufeinander abgestimmt sind, Erstellen eleganter und professioneller Visitenkarten.

- Individuelle Briefköpfe und Briefpapier: Konsistenz ist der Schlüssel zum Corporate Branding, und Sonderfarben sorgen für Einheitlichkeit bei allen Büromaterialien.

- Briefumschläge mit Logo: Die Verwendung von Sonderfarben auf Umschlägen steigert die optische Attraktivität und stärkt die Markenidentität.

- Marketingmaterialien: Von Broschüren bis hin zu Flyern, Der Volltonfarbdruck hebt wichtige Abschnitte hervor, Werbematerialien hervorstechen lassen.

- Produktverpackung: Reich werden, Einheitliche Farben auf der Verpackung sind entscheidend für den Wiedererkennungswert der Marke, Damit ist der Sonderfarbendruck die erste Wahl.

- Merchandise und Giveaways: Logos und Designs auf Artikeln wie Tragetaschen und T-Shirts kommen durch den Sonderfarbendruck lebendig zur Geltung.

- Exklusive Kunstdrucke: Künstler verwenden für limitierte Auflagen häufig Sonderfarben, um die Originalität und Genauigkeit ihrer Arbeit zu bewahren.

- Schilder und Displays: Wenn Sichtbarkeit und Klarheit an erster Stelle stehen, Der Volltonfarbdruck sorgt für kräftige Ergebnisse, auffällige Beschilderung.

Fazit

Der Sonderfarben-Siebdruck ist die Methode der Wahl, um kräftige Drucke zu erzeugen, lebendig, und präzise Entwürfe, insbesondere für Logos, einfache Grafiken, und Projekte, die eine außergewöhnliche Farbgenauigkeit erfordern. Dieser spezielle Prozess stellt sicher, dass jede Farbe perfekt aufeinander abgestimmt ist, liefert scharfe und konsistente Ergebnisse.

Zum professionelle Dienstleistungen im Bereich Vektorkunst, EMdigitizing ist hier, um zu helfen! Unser Team bietet hochwertige und erschwingliche Vektorisierungslösungen, die auf Ihre Bedürfnisse zugeschnitten sind. Plus, Neukunden erhalten ein exklusives 50% Rabatt auf ihre erste Bestellung. Lassen Sie sich dieses zeitlich begrenzte Angebot nicht entgehen – kontaktieren Sie uns noch heute und verbessern Sie Ihre Designs mit unseren Expertendiensten!