Wenn Sie vorhaben, Ihr Druckgeschäft auszubauen, ein automatische Siebdruckpresse kann ein kluges Upgrade sein. Es kann in kürzerer Zeit viele Hemden drucken, mit besserer Qualität und weniger Aufwand. Aber bevor Sie kaufen, Sie müssen ein paar wichtige Dinge verstehen, zum Beispiel, wie es funktioniert, wie viel Platz es braucht, und welcher Typ für Sie am besten geeignet ist.In diesem Ratgeber, Wir erklären Ihnen alles Schritt für Schritt in einfacher Sprache.

Was ist eine automatische Screen -Druckmaschine? Alles, was Sie wissen müssen

Verschiedene Arten automatischer Siebdruckmaschinen

Es gibt viele Arten von Druckmaschinen. Jedes ist für verschiedene Arten von Gegenständen geeignet. Werfen wir einen Blick auf die wichtigsten Typen, damit Sie denjenigen auswählen können, der zu Ihrem Unternehmen passt.

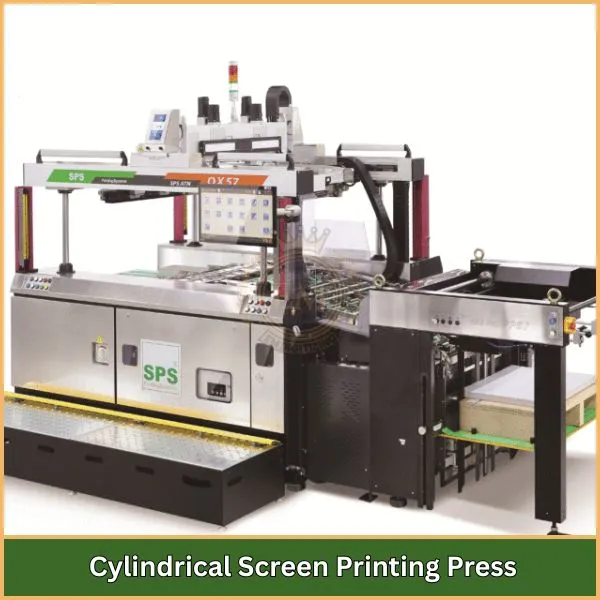

1. Zylindrische Siebdruckpresse

Diese automatische Siebdruckmaschine ist speziell für den Druck auf runden oder gekrümmten Oberflächen konzipiert.

Der Artikel, wie eine Flasche oder ein Becher, rotiert, während das Gerät gleichmäßig Tinte aufträgt.

Dadurch wird sichergestellt, dass die gesamte Oberfläche glatt wird, sauberer Druck.

Unternehmen, die Trinkgefäße bedrucken, Gläser, oder Kosmetikverpackungen verwenden häufig diese Art von Presse.

Es ist effizient und liefert hochwertige Ergebnisse bei allen Arten gebogener Produkte. Der Preis für eine zylindrische Presse liegt normalerweise zwischen $8,000 und $40,000.

2. Flachbett-Siebdruckmaschine

Für den Flachdruck eignen sich am besten Flachbett-Siebdruckmaschinen, harte Materialien.

In diesem Setup, Der Artikel bleibt auf einer ebenen Fläche an Ort und Stelle, und der Bildschirm fährt herunter, um Tinte darauf zu drücken.

Es wird häufig für Glasscheiben verwendet, Holzschilder, Kunststoffplatten, oder elektronische Teile.

Das Gerät ist dafür bekannt, sehr genaue und scharfe Ausdrucke zu erzeugen, insbesondere auf nicht flexiblen Materialien.

Es ist ideal für Branchen, die sich mit Schildern oder technischen Drucken befassen.

Der Preis für eine Flachbettpresse liegt normalerweise zwischen $15,000 zu $60,000.

3. Rotationssiebdruckmaschine

Die Rotationssiebdruckmaschine ist für die Herstellung von Bekleidung in großem Maßstab konzipiert.

Er verfügt über mehrere rotierende Druckplatten, mit denen viele Hemden oder Kleidungsstücke gleichzeitig bedruckt werden können.

Während sich jeder Gegenstand durch verschiedene Stationen dreht, es erhält nacheinander verschiedene Farben.

Dies macht die Maschine schnell und perfekt für Unternehmen, die T-Shirts in großen Mengen drucken, Uniformen, und andere Stoffprodukte.

Es wird häufig in großen Bekleidungsfabriken oder Print-on-Demand-Diensten eingesetzt.

Die Kosten für eine Rotationspresse liegen normalerweise zwischen $30,000 zu Ende $120,000, je nach Größe und Ausstattung.

4. Vier-Säulen-Siebdruckmaschine

Die Viersäulen-Siebdruckmaschine ist mit vier stabilen Stützsäulen ausgestattet.

Diese Beiträge tragen dazu bei, das Sieb und die Druckoberfläche im Gleichgewicht zu halten, Dies macht es zu einer großartigen Wahl für den Druck im Großformat, schwer, oder starre Gegenstände.

Es wird häufig zum Bedrucken von Blechen verwendet, Industrieteile, und große Platten, die starke Anforderungen erfordern, gleichmäßiger Druck beim Drucken.

Dieser Druckmaschinentyp eignet sich perfekt für Branchen, die technische Präzision bei ihren Drucken benötigen.

Die Preise für Vier-Säulen-Maschinen liegen typischerweise zwischen $10,000 zu $40,000.

5. Rolle-zu-Rolle-Siebdruckmaschine

Die Rolle-zu-Rolle-Siebdruckmaschine ist für den ununterbrochenen Druck auf langen Materialrollen wie Stoff ausgelegt, Vinyl, Film, oder Papier.

Das Material bewegt sich durch die Maschine, während wiederholte Designs kontinuierlich gedruckt werden.

Dieser Maschinentyp ist vollautomatisch und ideal für Unternehmen, die schnell arbeiten müssen, Großseriendruck, wie Tapetenhersteller, Stoffproduzenten, oder Hersteller von Verpackungsetiketten.

Wegen seiner Geschwindigkeit und Automatisierung, Diese Maschine ist teurer, kostet normalerweise zwischen $100,000 und $300,000 oder mehr.

Was Sie vor dem Kauf überprüfen sollten: Kauf einer automatischen Siebdruckmaschine?

Es kann Ihr Druckgeschäft schneller und professioneller machen. Aber bevor Sie eines kaufen, it’;Es ist sehr wichtig, einige wichtige Dinge zu überprüfen.

Wenn Sie eines davon überspringen, Sie könnten am Ende auf Probleme stoßen, die Sie Zeit kosten, Geld, oder beides.

Hier sind die wichtigsten Faktoren, die es zu berücksichtigen gilt:

- Kapazität des Druckvolumens

- Maschinentyp: Elektrisch vs. Pneumatisch

- Anzahl der Farben und Stationen

- Platzbedarf im Laden

- Benutzerfreundliche Steuerelemente

- Gesamtkosten und ROI

- Support und Wartung

- Sicherheits- und Effizienzmerkmale

- Strom- und Luftbedarf

1. Kapazität des Druckvolumens

Eines der ersten Dinge, über die Sie nachdenken sollten, ist, wie viel Sie regelmäßig drucken. Drucken Sie jede Woche nur ein paar Dutzend Hemden?, Oder bearbeiten Sie Hunderte von Artikeln für Großbestellungen?? Ihre Antwort wird Ihnen bei der Entscheidung helfen, welche Maschinengröße und -geschwindigkeit Sie benötigen.

Wenn Sie sich für eine Maschine entscheiden, die für Ihre Arbeitslast zu klein ist, Dies kann Ihr Geschäft verlangsamen und zu Rückständen führen. Andererseits, wenn Sie eine Hochleistungsmaschine kaufen, aber nicht genügend Bestellungen haben, um sie vollständig zu nutzen, Sie könnten Geld verschwenden.

Versuchen Sie, eine Maschine auszuwählen, die Ihre aktuelle Arbeitsbelastung bewältigen kann und Ihnen gleichzeitig Raum für Wachstum in den nächsten ein bis zwei Jahren bietet.

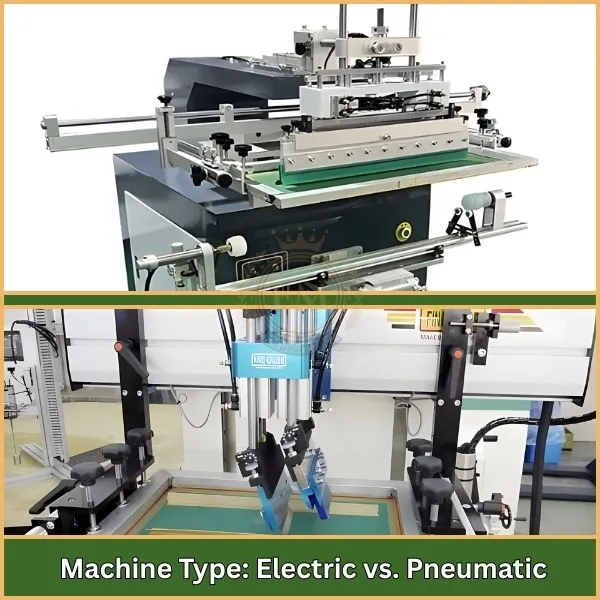

2. Maschinentyp: Elektrisch vs. Pneumatisch

Es gibt zwei Haupttypen von Pressen:

- Elektrische Pressen: Verwenden Sie Motoren. Sie sind leiser, verbrauchen Sie weniger Energie, und benötigen weniger Wartung.

- Pneumatische Pressen: Verwenden Sie Luftdruck. Sie sind in der Regel günstiger, benötigen aber einen starken Luftkompressor und können laut sein.

Wenn Sie ein kaufen Automatische Siebdruckmaschine für T-Shirts Unternehmen und möchten eine ruhige und saubere Umgebung, elektrisch wäre vielleicht besser.

Aber wenn Ihr Budget knapp ist, Pneumatik ist ebenfalls eine gute Wahl, seien Sie jedoch bereit, zusätzliche Lärm- und Luftgeräte in den Griff zu bekommen.

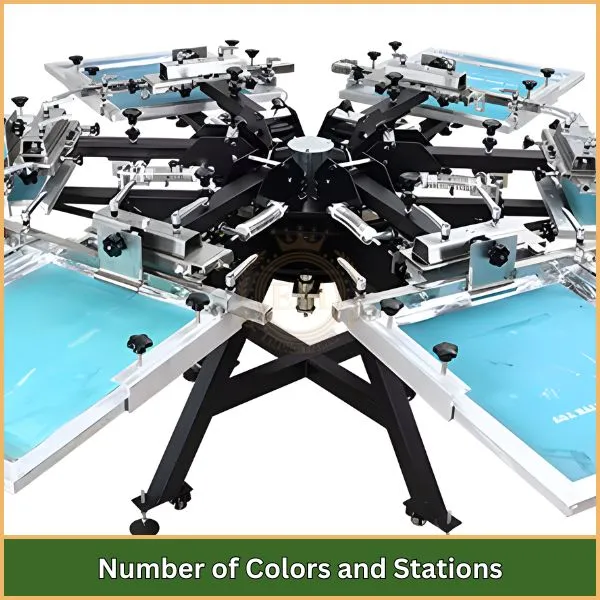

3. Anzahl der Farben und Stationen

Die Anzahl der Farben und Stationen einer Maschine bestimmt, wie komplex und schnell Ihre Drucke sein können.

Mit mehr Farbköpfen können Sie mehr Farben auf einmal drucken, Nützlich für mehrfarbige Logos oder detaillierte Grafiken.

Weitere Stationen (Teller) ermöglichen einen besseren Produktionsfluss.

Zum Beispiel, eine Maschine mit 8 Stationen bieten Platz zum Beladen, Drucken, blinkt, und alles auf einmal entladen, den Prozess beschleunigen.

Wählen Sie das Setup basierend auf den Designs, die Sie normalerweise drucken, und darauf, wie schnell Sie Bestellungen abschließen müssen.

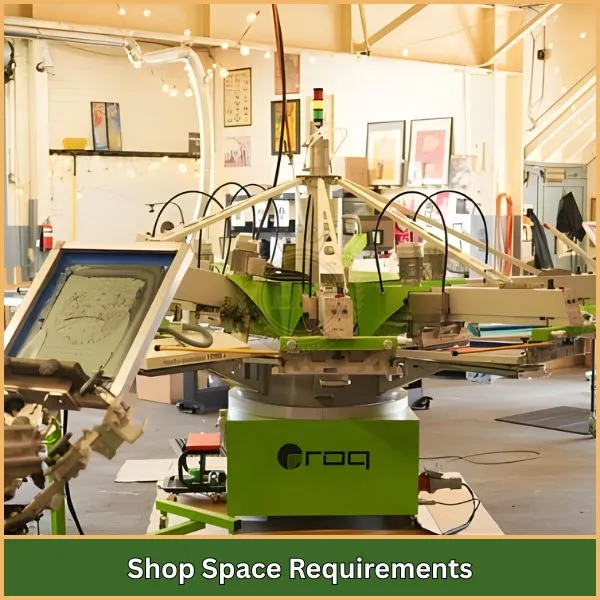

4. Platzbedarf im Laden

Diese Maschinen sind groß und benötigen viel Platz, nicht nur für die Maschine selbst, sondern auch für Betreiber, Bildschirme, Tinten, und Trockner.

Vor dem Kauf, Messen Sie Ihren Platz sorgfältig aus und vergleichen Sie ihn mit den Abmessungen der Maschine. Lassen Sie außerdem zusätzlichen Platz für sichere Bewegung und einfache Wartung.

Wenn Ihr Platz begrenzt ist, ein kompakter bzw kleine automatische Siebdruckmaschine passt vielleicht besser.

5. Benutzerfreundliche Steuerelemente

Einige Maschinen verfügen über manuelle Bedienelemente wie Knöpfe und Schalter, während andere mit digitalen Touchscreens ausgestattet sind.

Touchscreen-Systeme sind benutzerfreundlicher, Speichern Sie Ihre Jobeinstellungen, und ermöglichen schnelle Anpassungen.

Dies ist bei Nachbestellungen sehr hilfreich und verringert das Risiko menschlicher Fehler.

Manuelle Maschinen sind günstiger, erfordern aber mehr Schulung und Zeit.

Choose a system that matches your team’;Ihre Erfahrung und Ihr Bedürfnis nach Schnelligkeit und Genauigkeit.

6. Gesamtkosten und ROI

Der Preis der Maschine ist nur der Anfang. Sie müssen auch ein Budget für die Installation einplanen, Versand, Ausbildung, Zubehör, zukünftige Wartung, und Reparaturen. Berechnen Sie Ihre Kapitalrendite (ROI) indem Sie herausfinden, wie viele Artikel Sie jeden Monat drucken und verkaufen müssen, um Ihre Kosten zu decken und Gewinne zu erzielen.

Eine etwas teurere Maschine, die schneller arbeitet und länger hält, könnte auf lange Sicht einen besseren Wert bieten als ein günstigeres Modell, das häufig ausfällt.

7. Support und Wartung

Egal wie gut eine Maschine ist, Es wird irgendwann Wartung und Support benötigen. Stellen Sie sicher, dass die Marke oder der Lieferant einen angemessenen Kundenservice bietet, einfacher Zugang zu Ersatzteilen, und hilfreiche Benutzerhandbücher oder Schulungen.

Wenn die Maschine kaputt geht und Sie nicht schnell Hilfe bekommen können, Ihr Unternehmen könnte zum Erliegen kommen. Wählen Sie eine Maschine mit starkem Kundendienst.

8. Sicherheits- und Effizienzmerkmale

Suchen Sie nach Maschinen, die über hilfreiche und sichere Funktionen wie Not-Aus-Tasten verfügen, Bildschirmklemmen mit Schnellverschluss, berührungslose Steuerungen (um den Abstand zwischen Bildschirm und Stoff anzupassen), und einstellbarem Rakeldruck.

Diese Funktionen machen Ihre Arbeit sicherer, Schneller, und genauer, insbesondere bei langen Schichten oder bei der Bearbeitung mehrerer Aufträge pro Tag.

9. Strom- und Luftbedarf

Prüfen Sie, welche Art von elektrischer Energie die Maschine benötigt. Die meisten automatischen Maschinen verwenden 220 V oder 3-Phasen-Strom. Wenn Sie eine pneumatische Maschine verwenden, Sie benötigen außerdem einen starken Luftkompressor, der mit der Produktion mithalten kann.

Stellen Sie sicher, dass Ihr Geschäft diesen Stromanforderungen gerecht wird. Wenn nicht, Möglicherweise müssen Sie Ihr elektrisches System aufrüsten oder einen neuen Kompressor kaufen, was die Gesamtkosten erhöht.

So pflegen Sie Ihre automatische Siebdruckmaschine?

Wenn Sie Ihre Maschine pflegen, bleibt sie länger funktionstüchtig und beugt Problemen vor. Befolgen Sie diese Tipps:

- Reinigen Sie die Rakel, Teller, und Bildschirme nach jeder Schicht

- Staub abwischen, Fussel, und getrocknete Tinte

- Überprüfen Sie wöchentlich, ob die Riemen abgenutzt sind oder sich die Schrauben gelöst haben

- Bewegliche Teile schmieren

- Aktualisieren Sie die Software, wenn Ihr Gerät über einen digitalen Bildschirm verfügt

- Reinigen Sie den Luftkompressor regelmäßig (für pneumatische Pressen)

- Führen Sie ein Logbuch über Reparaturen und Reinigungen

Eine gute Wartung bedeutet weniger Verzögerungen und eine bessere Druckqualität.

Abschließende Gedanken: Sollten Sie sich eine automatische Druckmaschine zulegen??

Wenn Ihr Unternehmen mehr Bestellungen erhält und Sie Zeit sparen und gleichzeitig besser drucken möchten Entwürfe, Dann kann eine automatische Siebdruckmaschine eine gute Investition sein. Aber bevor Sie kaufen, Stellen Sie sich ein paar einfache Fragen: Haben Sie genügend Platz in Ihrem Geschäft?? Kann Ihr Geschäft mit der benötigten Strom- oder Luftversorgung umgehen?? Drucken Sie genug, damit sich die Maschine lohnt?? Haben Sie ein Team, das den Umgang mit der Maschine erlernen kann?? Und sind Sie bereit, es sauber und gepflegt zu halten??

Ebenfalls, behalte es im Hinterkopf, Selbst die beste Maschine benötigt zum Drucken hochwertige Designs. Viele Menschen haben Probleme, weil ihre Kunstwerke noch nicht fertig sind oder von schlechter Qualität sind.

Das ist wo EMDigitalisierung kann helfen. Wir bieten professionelle Vektorgrafiken und Digitalisierung von Stickereien die bereit sind, mit Ihrer Maschine verwendet zu werden. Sie erhalten hochwertige Designs, schnelle Lieferung, und volle Unterstützung, wann immer Sie sie brauchen. Plus, Wir bieten 50% aus deinem erste Bestellung und zusätzliche Rabatte auf Massendesigns.

Verschwenden Sie also keine Zeit damit, schlechte Kunstwerke zu reparieren. Lassen EMDigitalisierung Kümmern Sie sich um Ihre Designs, während Sie sich auf den Druck und das Wachstum Ihres Unternehmens konzentrieren!

Häufig gestellte Fragen

Eine automatische Presse ist eine beim Siebdruck eingesetzte Maschine, die den Großteil der Arbeit selbst erledigt. Anstatt Tinte von Hand durch das Sieb zu drücken, Die Maschine bewegt alles automatisch, Dadurch wird das Drucken großer Bestellungen deutlich schneller und einfacher.

Mit einer Siebdruckmaschine können Sie ein Design auf Stoff übertragen, indem Sie das Sieb ruhig halten und Tinte durch das Sieb auftragen. Es stellt sicher, dass jeder Druck an der gleichen Position erfolgt und sorgt für klare Ergebnisse, Scharfe Designs auf Artikeln wie T-Shirts oder Hoodies.

Beim automatischen Siebdruck werden Motoren und Einstellungen zur Steuerung des Druckvorgangs eingesetzt. Sie legen das Hemd auf die Maschine, einen Knopf drücken, Und es druckt jede Farbschicht, ohne dass jemand die Siebe manuell bewegen oder die Tinte auspressen muss.

Mit einer Maschine wie dem Trooper, Sie können herumdrucken 180 Hemden pro Stunde, sogar bei Designs, die sechs Farben verwenden. Diese Geschwindigkeit ist ideal für Unternehmen, die viele Bestellungen erhalten und diese schnell erledigen müssen.

Zum richtigen Fixieren der Tinte beim Siebdruck, Sie müssen das bedruckte Hemd erwärmen 320°F (160°C). Eine Wärmepresse funktioniert am besten und sollte gepresst werden um 40 Sekunden. Wenn Sie ein Bügeleisen verwenden, Wenden Sie die Hitze gleichmäßig an, bis das gesamte Design richtig erhitzt ist.