Ich erinnere mich noch an das erste Mal, als ich es versuchte Hut stickende Digitalisierung. Ich dachte, „Wie schwer könnte es sein?Ich hatte meine Maschine, Ein ordentliches Logo, und Erfahrung mit flachem Stoff.

Aber der Moment, in dem diese Nadel die gekrümmte Front der Kappe traf, Alles fiel auseinander, Stiche übersprungen, Das Design verlagerte sich, Und das Endergebnis sah nichts aus wie das, was ich mir vorgestellt hatte.

Dann traf es mich: Bei der Digitalisierung für Hüte geht es nicht nur darum, eine Stichdatei zu erstellen. Es geht darum zu verstehen, wie Hüte gebaut werden, Wie der Stoff reagiert, und wie das Design geformt und platziert werden muss, um auf einer Oberfläche zu arbeiten, die nicht flach ist.

Dieser Leitfaden ist genau das, was ich damals wünschte, ich hätte es damals. If you’;Fangen Sie gerade erst an und möchten diese frühen Fehler vermeiden, Ich werde dich durch alles führen, einfach, deutlich, und wie ein Freund, der dir die Seile zeigt.

Lassen Sie uns den richtigen Weg auf den richtigen Weg machen.

Hut stickende Digitalisierung: 5 Wichtige Tipps, die Sie sich nicht leisten können, um zu verpassen

Tipp #1: Beginnen Sie mit dem richtigen Design und platzieren Sie es intelligent

Wenn es darum geht Hut stickende Digitalisierung, Ihr Design muss nicht nur gut aussehen, Es muss gut passen und auf einer gekrümmten Oberfläche sauber näher sein.

Im Gegensatz zu flachen Kleidungsstücken, Hüte haben Nähte, Kurven, und begrenzter Raum.

Ein häufiger Fehler des Anfängers ist die Platzierung des Designs zu hoch, Zu breit, oder direkt über der Mitte Naht, das kann das Endergebnis verzerren.

Um das zu vermeiden, Sie müssen über drei Dinge zusammen nachdenken: das Art des Hutes, das Form der Frontplatte, und wie du Das Design sollte dimensioniert und platziert werden.

Hier ist ein klarer Leitfaden, mit dem Sie alles richtig anpassen können:

Huttyp | Frontform | Design-Platzierung | Maximale Designgröße (H × w) | Empfohlener Designstil |

Strukturierte Baseballkappe | Gebogen, feste Front | Etwas unterhalb der Mittellennaht | 2.25″; – 2.5″; × 4.5″; – 5″; | Fette Logos, mittelschwerer Text |

Trucker Hut | Semi-Flat-Schaum vorne | Zentriert, Vermeiden Sie Obere Ecken | 2.5″; – 2.75″; × up to 5″; | Lichtfüllung, einfache Vektorformen |

5-Panelhut | Flache Frontplatte | Kann höher und breiter platzieren | Up to 2.75″; × 5.5″; | Logos mit feinem Detail oder breitem Text |

Mütze | Dehnbarer Strick vorne | Untere vorne (Um eine Dehnungsverzerrung zu vermeiden) | 1.5″; – 2″; × 3″; – 4″; | Initialen, Kleine Ikonen, kurzer Text |

Unstrukturierter Vater Hut | Weich, zusammenklappbar | Zentriert niedriger als gewöhnlich | 2″; – 2.25″; × 4″; – 4.5″; | Einfache Grafik, Saubere Monogramme |

Bevor Sie in Ihrer Datei auf "Speichern" klicken, Nehmen Sie sich einen Moment Zeit, um zu fragen: Ist mein Design für diesen Hut geformt? Wird es sauber unter der Naht sitzen?? Ist es innerhalb des erlaubten Raums lesbar?

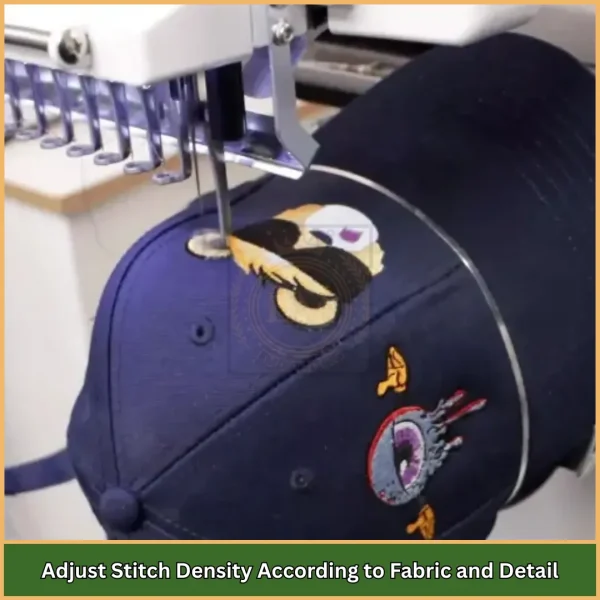

Tipp #2: Passen Sie die Stichdichte nach Stoff und Detail ein

Eine Sache, die viele Anfänger nicht erkennen, ist, wie viel Maschendichte Beeinflusst Stickergebnisse auf Hüten. Die falsche Dichte kann Fadenbruch verursachen, ungleichmäßige Textur, oder kräuseln, vor allem auf gebogenen oder dicken Materialien.

Anstatt die gleichen Dichteeinstellungen für zu verwenden Jedes Design, Passen Sie es an Ihr Stoff- und Designdetail an. Dickere Materialien wie Leinwand benötigen eine engere Dichte, Während Schaum- oder Strickstoffe lockerer Füllung und sorgfältige Unterlage erfordern.

Hier ist ein hilfreicher Leitfaden:

- Kleiner Text (4–6 mm): Verwenden Sie 0,40–0,45 mm Dichte

- Mittlere Formen (7–12 mm): Versuchen Sie 0,35–0,40 mm

- Große Elemente (13mm+): Mit 0,30 bis 0,35 mm enger werden

- Knockdown -Stich für Schaum: Verwenden Sie 0,50–0,60 mm

Wenn Sie verwenden Software zum Digitalisieren von Stickereien, Stellen Sie sicher.

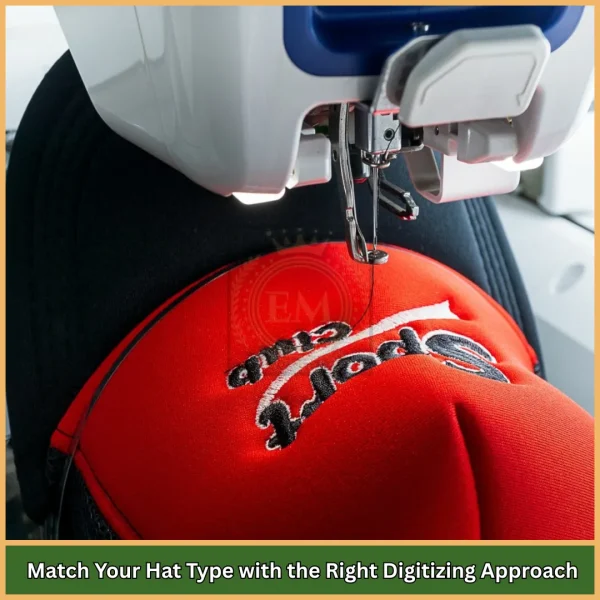

Tipp #3: Passen Sie Ihren Hutentyp mit dem richtigen Digitalisierungsansatz an

Nicht alle Hüte sind gleich gebaut, Und das bedeutet, dass Sie sie während der Digitalisierung nicht gleich behandeln können.

EIN Baumwoll -Kappe Wird Stiche gut mit Standardunterlagen halten, während a Trucker Caps Schaumstofffront braucht Knockdown -Stiche, um die Schwellung zu stabilisieren.

EIN Mütze, auf der anderen Seite, Strecken, So können enge Stiche verzerren oder auseinander ziehen.

Hier finden Sie eine kurze Referenz für den Umgang mit verschiedenen Hutstoffen:

Huttyp | Material | Digitalisierungstipp |

Baumwoll -Kappe | Twill | Verwenden Sie die mittlere Dichte mit leichter Zugkompensation |

Schaumstoff-Front-Trucker-Hut | Schaum + Netz | Knockdown -Stich, weiche Füllung, um zu sinken, um zu sinken |

Leinwand oder Denimkappen | Schwere gewebte Stoffe | Verwenden Sie eine engere Füllung, Starke Unterlage, scharfe Nadel |

Mesh-Back-Kappen | Plastiknetz | Nur Stich auf fester Frontplatte, Mesh vermeiden |

Mütze | Dehnbares Strick | Verwenden Sie eine offene Füllung, Kugelnadel, Lichtunterdrückung |

Wenn Sie wissen, dass Ihr Huttyp am häufigsten am häufigsten ist Cap Stickfehler, Besonders bei der Auswahl von Nadeltypen und Stabilisatoren.

Tipp #4: Verwenden Sie eine Maschine, die für Hüte gebaut wurde

Lassen Sie uns über Tools sprechen. Sie können die perfekte Datei haben, Aber wenn Ihre Maschine nicht für Hüte gedacht ist, Das Ergebnis kann immer noch enttäuschen. Zum CAP Stickerei digitalisiert, Sie benötigen eine Maschine, die gekrümmte Oberflächen unterstützt, Kappenrahmen, und schnelles Nähen.

Suchen Sie nach diesen Maschinenfunktionen:

- Multi-Needle-Kompatibilität (Für automatische Farbänderungen)

- Cap -Rahmenunterstützung (Wesentlich für Griff und Kurvenkontrolle)

- Bildschirmvorschau (Überprüfen Sie die Designposition vor dem Nähen)

- Einstellbare Spannungseinstellungen (Besonders für dicke Kappen)

Wenn es um Reifen geht, zwingen Sie keinen flachen Reifen auf eine gekrümmte Kappe. Verwenden Sie CAP-spezifische Reifen. Hier ist das, was am besten passt:

- Trucker Caps: Extra breiter gekrümmter Kappenrahmen

- Baseballmützen: Gebogener Weitkappenrahmen

- Mützen: Kleiner flacher oder zylindrischer Reifen

- 5-Tafelhüte: Flat Cap -Rahmen für saubere Platzierung

Die Verwendung der richtigen Kombination von Maschine und Hoop sorgt für die Stabilität, die Ihr Design für Reinigung benötigt, konsistente Ergebnisse.

Tipp #5: Speichern Sie im richtigen Format und überprüfen Sie alles doppelt

Sobald Ihre Datei fertig ist, Der letzte Schritt ist der Exportieren. Aber nicht beeilt, Denn das Speichern im falschen Format oder fehlende Schlüsselbefehle kann Ihre Designausführung vollständig durcheinander bringen.

Hier ist eine kurze Checkliste:

- Wählen Sie den richtigen Dateityp für Ihren Computer aus: .Sommerzeit, .PES, oder .EXP

- Bestätigen Sie die Farbsequenz entspricht Ihren Maschinenfäden

- Aufräumen Sprungstiche Sie überladen also nicht Ihre letzte Arbeit

- Hinzufügen Befehle trimmen zwischen Farbblöcken

- Sicherstellen Start- und Endpunkte Folgen Sie einem logischen Pfad

Und wenn Sie sich nicht sicher sind, welches Format oder die Einstellungen am besten sind, it’;S okay, um Hilfe zu bitten. Das ist wo Professionelle Stickdienstedienste kann einen großen Unterschied machen.

Fazit

So, Wenn Sie so weit gefolgt sind, Das weißt du jetzt Hut stickende Digitalisierung ist nichts, was man beiläufig nähert. Es ist technisch. Es ist präzise. Aber vor allem, Es ist überschaubar, wenn Sie die fünf Kernbereiche verstehen, über die wir gesprochen haben.

And if you’;Starten Sie einfach oder möchten Sie perfekte Ergebnisse ohne alle Versuch und Irrtum, Lassen Sie einen Experten nicht die technische Seite erledigen? Bei EMdigitalisieren, Wir wissen genau, was es braucht, um die Kappen zu digitalisieren.

Unser globales Team arbeitet 24/7, Unsere Preise sind flach, Unsere Ergebnisse sind garantiert, Und wir bieten an superschnelle Bearbeitungszeiten, oft innerhalb von 4 bis 12 Stunden. Plus, Du wirst bekommen 50% Rabatt auf Ihre erste Bestellung, So können Sie unseren Service ohne Druck testen.

Don’;Überlasse deine Kappen dem Zufall. Jetzt bestellen, Und lassen Sie uns Ihnen helfen, wie ein Profi zu nähen.

Häufig gestellte Fragen

Stickdigitalisierung mag am Anfang schwierig erscheinen, Besonders bei der Arbeit mit Hüten aufgrund ihrer gekrümmten Oberfläche. Jedoch, Sobald Sie die Grundlagen verstanden haben und sich mit Ihrer Software vertraut machen, Es wird viel einfacher zu verwalten. Viele Anfänger lagern digitalisiert, bis sie mehr Vertrauen gewinnen.

Zum Digitalisieren für die Kappenstickerei, Sie müssen die Form und Struktur des Hutes berücksichtigen. Beginnen Sie immer die Nähte aus dem Zentrum und bewegen Sie sich nach außen, um die Verzerrung zu verringern. Eine ordnungsgemäße Zugkompensation ist wichtig, damit das Design nicht verschoben wird. Für Schaumstoffkappen, Knockdown -Nähte hilft dabei, den Bereich vor dem Hauptdesign zu verflachten. Stellen Sie sicher, dass Ihr Design zum Stickbereich passt, Und vergessen Sie nicht, es vor der endgültigen Produktion auf einer Probe zu testen. zuletzt, Speichern Sie die Datei in einem Format, das mit Ihrer Maschine kompatibel ist.

CAP Stickerei ist eine Methode zum Dekorieren von Hüten durch Nähte Logos, Namen, oder Grafiken mit einer Stickmaschine. Da sind Hüte nicht flach wie Hemden, Sie erfordern einen besonderen Ansatz zur Digitalisierung, der die gekrümmte Oberfläche berücksichtigt, um saubere und genaue Ergebnisse zu erzielen.

Absolut. Stickmützen können eine sehr profitable Nische sein, Vor allem, weil benutzerdefinierte Kappen immer nach Teams gefragt sind, Unternehmen, Veranstaltungen, und Geschenke. Die Einrichtungskosten sind relativ niedrig, und Sie können sowohl Einzelbestellungen als auch Massenangebote anbieten, Das bringt oft eine gute Gewinnspanne mit.